Universal Motor Commutator Manufacturer in China

XDC is a leading commutator manufacturer in China, supplying high-performance copper commutators for universal motors used in power tools, household appliances, automotive systems and light industrial equipment worldwide. We design and produce complete commutator families covering miniature to medium frame sizes, with tight tolerances for high-speed AC/DC operation and long brush life.

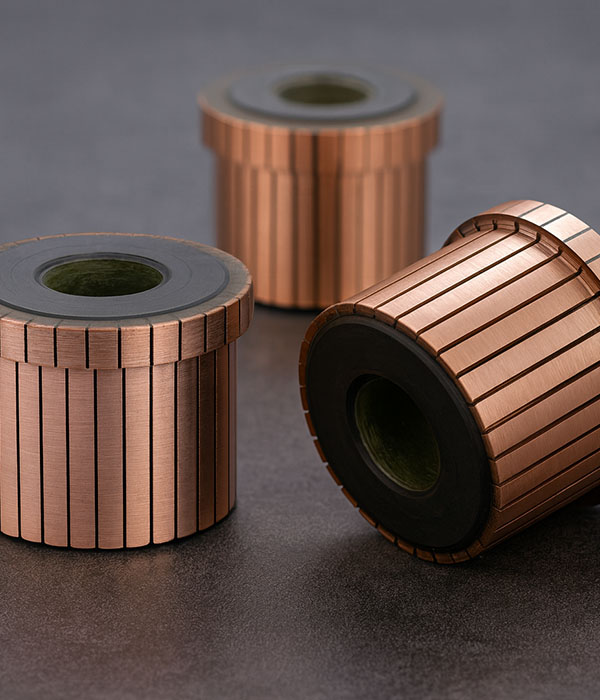

Universal Motor Commutator Manufactured by XDC

Inspect XDC’s line of Universal Motor commutators, optimized for high-speed power tools and appliances. We produce custom parts aligned exactly with your engineering files. Our approach guarantees satisfaction by delivering pre-production samples prior to volume manufacturing. Browse our finished products below, and directly send us your drawings to get a quote.

5-Bar Micro Commutator

The 5-segment geometry reduces electrical erosion at the brush interface compared to 3-slot designs. This 5.6mm unit is engineered to maximize the service life of high-cycle micro motors.

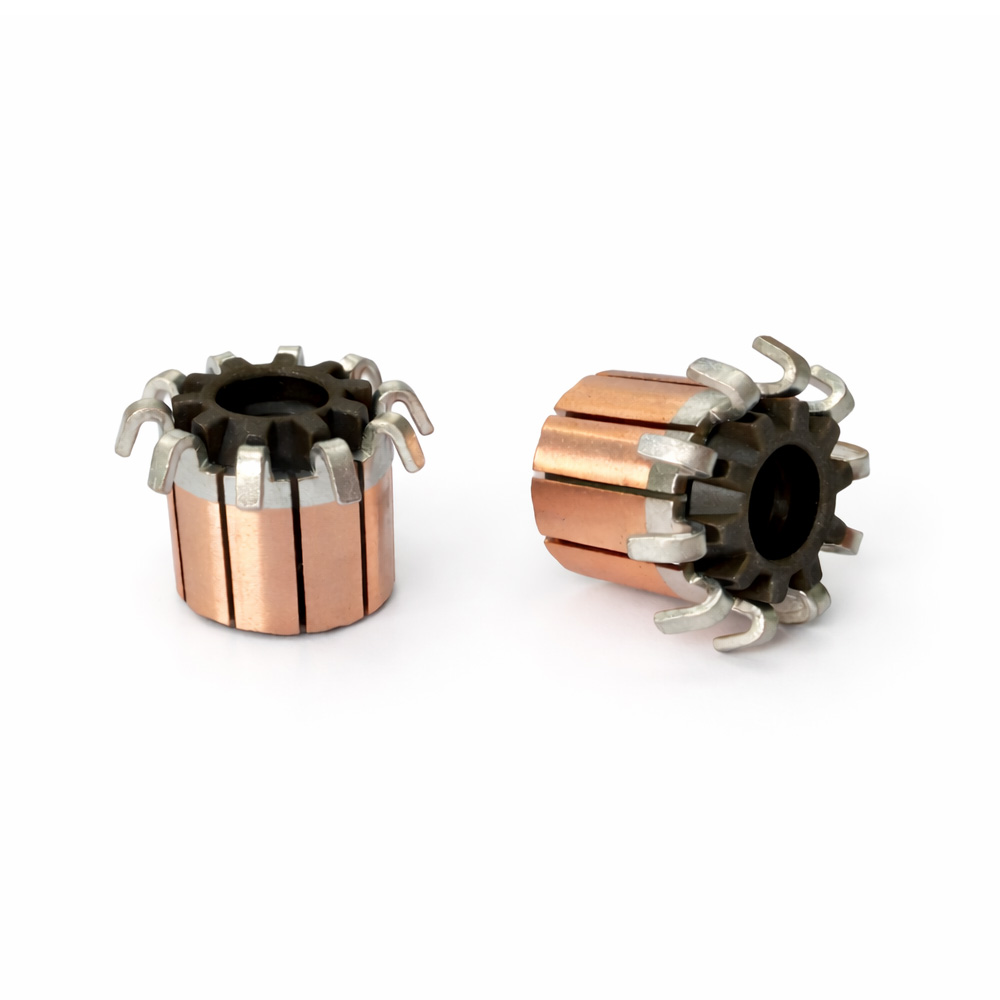

3-Segment Strain-Relief Commutator

The bent-hook profile is engineered to minimize stress concentration at the wire connection point. This design safeguards against wire fatigue and breakage, ensuring the structural integrity of the winding circuit.

High-Retention 3-Segment Commutator

Engineered with reinforced anchoring features, this 7.6mm unit exhibits superior copper bar pull-out strength. This robust construction prevents segment loosening, ensuring reliability even under sustained mechanical vibration.

High-Conductivity Micro Commutator

Crafted from high-purity copper alloy, this 2.9mm unit minimizes contact resistance. It is designed to maximize energy efficiency in battery-powered, low-voltage micro motor systems.

42mm Variable-Load Commutator

Optimized for 4-pole industrial motors, this 28-segment unit (42mm OD) excels in variable-load environments. Its robust design maintains electrical stability during rapid torque fluctuations, ensuring reliable heavy-duty operation.

14-Slot Current-Distributing Commutator

The high-segment count allows for simultaneous brush contact across multiple bars. This effectively distributes current load, minimizing localized overheating and ensuring uniform wear patterns for professional motor applications.

Wear-Optimized 10-Bar Commutator

Specific copper alloy hardness is utilized in this 15mm, 10-slot unit to strictly match brush grade specifications. This material pairing prevents uneven wear and threading, ensuring consistent performance over the motor’s lifespan.

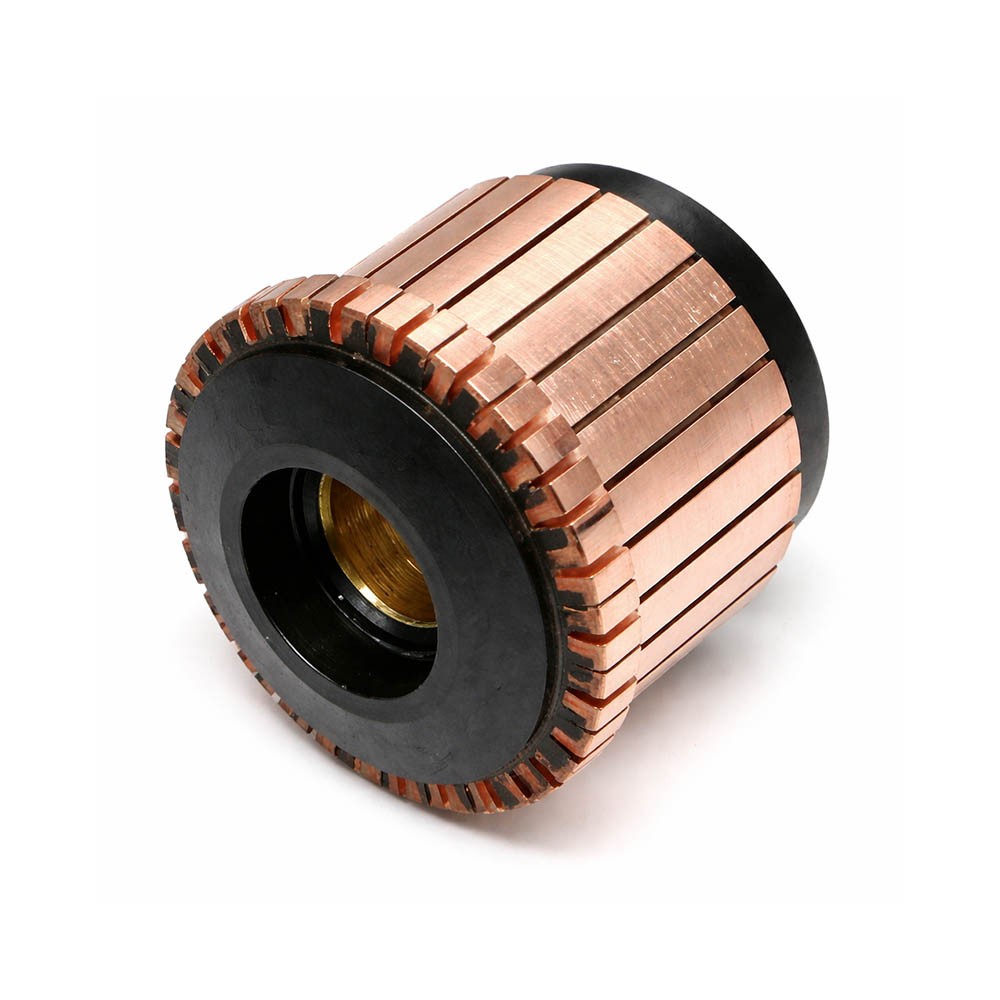

15.2mm OD 10-Slot Copper Commutator

Precision 15.2mm OD motor commutator with 10 slots, featuring durable copper segments and reliable insulation for smooth switching, low sparking, stable conductivity, and long service life.

Key design features of Our Universal Motor Commutator

XDC focuses on delivering a commutator platform that balances conductivity, mechanical strength and insulation performance for high-speed universal motors.

Optimized for Assembly

Hook-type segmented copper construction for easy connection to armature windings.

Superior Conductivity & Durability

High-conductivity copper segments, with optional low-silver copper alloy (~0.03–0.08% Ag) for improved hardness and wear resistance.

Robust Insulation Core

Precision-moulded insulating hub (phenolic / bakelite / engineered resin) for excellent thermal and mechanical stability.

Maximum Service Life

Low-sparking design to extend brush and commutator life, reducing maintenance and downtime.

High-Speed Stability

Excellent concentricity and minimal bar-to-bar deviation to reduce brush bounce, noise and arcing at high speed.

Surface finishing and cleaning

Available in hook, riser, shell and planar commutator variants to match different armature constructions.

Customisation Options for Your Commutator

Every motor platform has its own mechanical and electrical requirements. XDC provides full customisation support to give you a commutator that fits your armature and operating profile precisely.

We can tailor:

- OD, ID and total height

- Copper height and riser/slot dimensions

- Segment (bar) count and bar pitch

- Commutator type: hook, riser, shell or planar

- Copper grade and optional silver content

- Hub material and colour

- Bush / sleeve presence and material

- Dynamic balancing requirements

- Special insulation or high-temperature requirements

Quality, Testing & Reliability of XDC Commutators

For high-speed series motors, the commutator is one of the most stressed parts of the system. XDC uses robust processes and comprehensive testing to ensure long-term reliability.

Mechanical and electrical testing

Each design undergoes a defined validation program, which may include:

- Spin testing at elevated temperature and high rpm to confirm that OD, bar-to-bar deviation and hub integrity remain within tight limits.

- Bar-to-bar electrical testing to identify shorted or open segments.

- Bar-to-shaft high-potential (HiPot) testing at around 1500 V to verify insulation to the shaft or bore.

- Insulation resistance measurement (typically >50 MΩ at 500 V).

- Dimensional inspection of OD, ID, total height and concentricity.

- Visual inspection to check for cracks, bubbles and defects in the hub and copper segments.

Process control

- Controlled copper alloy and resin sourcing

- CNC machining and precision moulding where required

- In-process checks for critical dimensions and runout

- Dynamic balancing for high-speed rotors

The result is a commutator that supports stable commutation, low EMI, reduced brush wear and predictable service life.

Installation & Maintenance Guidelines for XDC Commutators

Correct assembly and maintenance are essential to get the full benefit from our commutators.

Installation notes

- Ensure the commutator seats properly on the rotor shaft, respecting specified interference or clearance fits.

- Check that armature windings are correctly connected to the hook or riser segments, with no loose connections or solder spatter.

- Align brush holders so that the brushes track the commutator surface evenly.

- Set brush spring pressure according to the motor design: too low causes sparking and noise; too high increases wear.

- Verify the neutral plane or brush position to minimise commutation losses and arcing.

Maintenance tips

- Periodically inspect for sparking, pitting, bar discoloration or bar lifting.

- Keep the commutator surface clean from excessive carbon dust.

- Replace worn carbon or graphite brushes before they damage the commutator track.

- If the surface becomes rough or out-of-round, a controlled resurfacing and undercutting process can extend service life.

Our team can provide guidelines for commutator maintenance programs in demanding applications such as power tools and vacuum cleaner motors.

Why Choose XDC as Your Universal Motor Commutator Supplier

Choosing the right partner is as important as choosing the right design. Here is why global customers work with XDC for their commutator programs:

Broad product coverage

Our portfolio covers OD from 2.5 mm to 150 mm, supporting everything from miniature motors to larger industrial and automotive platforms.

Strong production capacity

Our monthly output capability is in the multi-million piece range, ideal for OEM and ODM projects.

Consistent quality from China to the world

As a leading commutator manufacturer in China, we supply customers across Asia, Europe, the Americas and other regions with stable lead times and repeatable quality.

Cost-effective solutions

Optimised designs, local raw-material sourcing and efficient manufacturing help you reduce total motor cost without sacrificing performance.

Typical end-use applications

We engineer commutators for a wide range of motor platforms and industries, including:

Small industrial & workshop equipment

Portable or bench-top machines that require high output power from a small frame size.

Kitchen appliances

Blenders, juicers and mixers where the motor must deliver strong starting torque and operate over a wide speed range.

Handheld & portable power tools

Drills, grinders, saws, rotary hammers, electric planers and sanders with high-speed armature winding designs and variable loads.

General household appliances

Hair dryers, compact fans and other small appliances based on high-speed universal motors.

Automotive small motors

Wiper motors, window-lift motors, small pump motors and auxiliary drives in 12–24 V systems.

E-bikes and light electric motorcycles

Compact drives where vibration resistance and secure segment anchoring are critical.

Contact XDC for Your Next Commutator Project

Whether you are developing a new appliance motor, localising an existing design or looking for a stable supplier, XDC is ready to support you from concept to mass production.

Tell us about your motor, share your drawings and target specifications, and our engineers will respond with a tailored proposal, including design suggestions, sample plan, lead times and pricing.

Talk to XDC today about your next universal motor commutator project and let us help you build motors that run cleaner, longer and more efficiently.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ About Universal Motor Commutator Selection & Use

A1: Start from your armature design and rated voltage. The shaft diameter sets the bore, the stator and frame define the maximum OD and height, and the winding layout determines the required segment count. Send us your armature drawing and electrical targets, and our engineers will recommend OD, height and bar count combinations that provide good commutation performance and manufacturability.

A2: Yes. If you provide a sample or detailed drawing with dimensions, materials and basic motor data, we can reverse-engineer the commutator and offer a compatible or improved alternative, often with optimised cost and availability.

A3: Depending on the product and agreement, we can perform bar-to-bar testing, bar-to-shaft high-potential testing, insulation resistance measurement, dimensional checks, spin tests and visual inspection, with reports supplied as part of the quality documentation.

A4: For new designs or localisation projects, we can provide sample lots for motor prototype testing. Once the design is validated, we move to pilot production and then mass production under agreed MOQs.

A5: Lifespan depends on the motor design, load, speed, ventilation and brush grade. With correctly selected brushes and proper cooling, our commutators are designed to support the intended service life of standard appliance and power-tool platforms.

A6: Please share a drawing or sample, expected annual volume, application type, key dimensions, required tests and any special requirements (for example, high temperature, specific standards or custom packaging). The more detail you provide, the faster and more accurate our quotation will be.

A7: Yes. We can work with your brush suppliers or recommend brush grades and contact pressures that match our commutator materials, helping to reduce sparking, noise and wear.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…