Custom Commutators for Your Motor Projects

XDC is an ISO 9001 certified commutator manufacturer in China based in Dongguan. We build commutators strictly to customer drawings and specifications, covering engineering review, tooling evaluation, prototyping, inspection, and mass production. Upload your drawing with quantity and material requirement—our team will return a quotation and practical manufacturability notes

About us

Your Partner for Drawing-Based Commutator Manufacturing

Founded in 2016 in Dongguan, Guangdong, XDC is a manufacturing-focused team of 100+ employees. We operate under an ISO 9001 quality system with batch traceability and organized documentation. Our workflow and communication are designed for long-term OEM supply, enabling smooth qualification and audits without disrupting your engineering intent.

Full Manufacturing Capabilities

One-stop commutator manufacturing: stamping, precision turning/machining, silver brazing/soldering, assembly, in-line inspection, and (when required) dynamic balancing—built strictly to your drawings with controlled processes.

Engineering-Grade Customization

Drawing-based OEM/ODM with DFM-style feedback, material selection per BOM, tolerance control on segments/concentricity/runout, and insulation/hi-pot testing as specified. NDA supported.

Fast RFQ & Reliable Delivery

Quotation and manufacturability notes within 12 hours. Clearly scheduled builds from prototype to mass production, backed by batch traceability and documented QC to streamline global shipments.

Products

Products — Organized for Procurement Clarity

As a commutator manufacturer in China, XDC builds commutators strictly to customer drawings. We group our products by structure and by application so that engineers and buyers can quickly match requirements, review manufacturing notes, and send drawings for quotation.

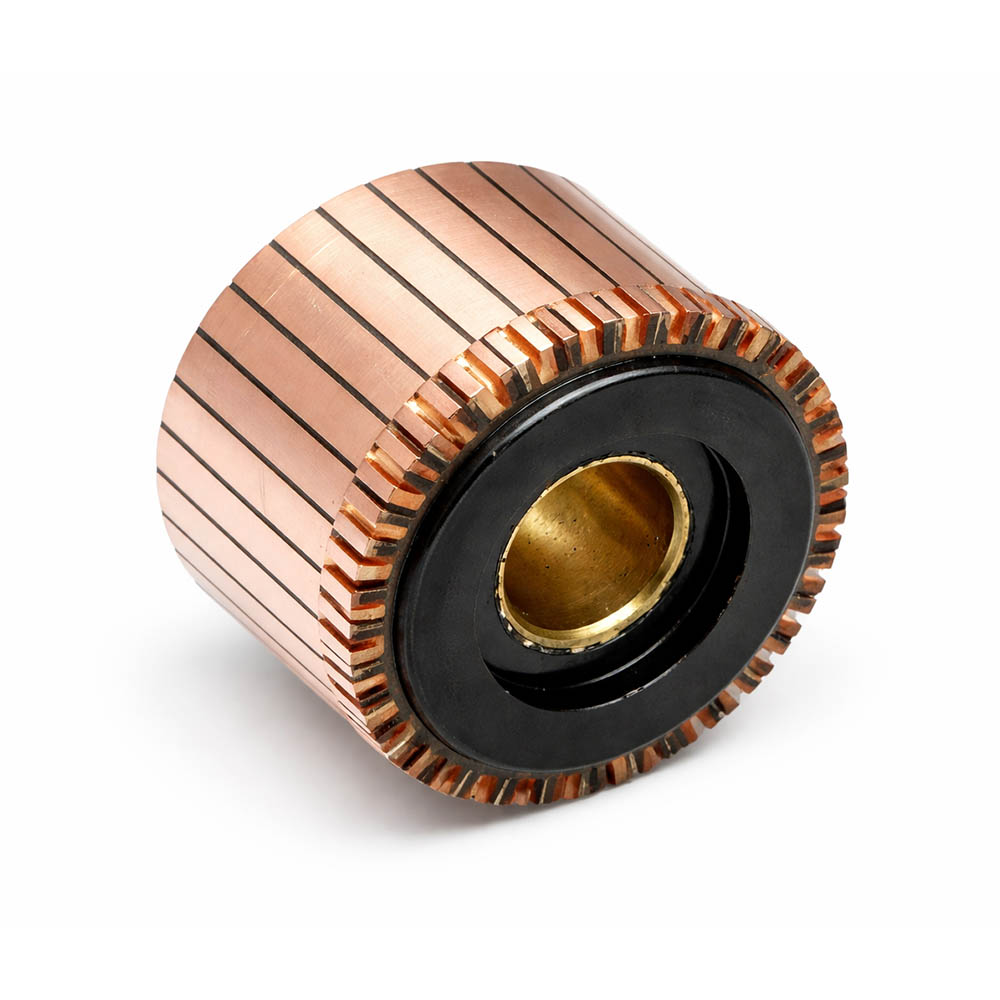

Hook Type Commutators

Designed for a wide range of DC motors. Stable segment alignment and controlled finishing deliver consistent commutation. Silver brazing/soldering and machining are performed to your specifications for repeatable OEM production.

Slot Type Commutators

A robust structure suited to demanding duty cycles. We control dimensions, concentricity, and runout per drawing, with process checks that help maintain uniform performance across batches.

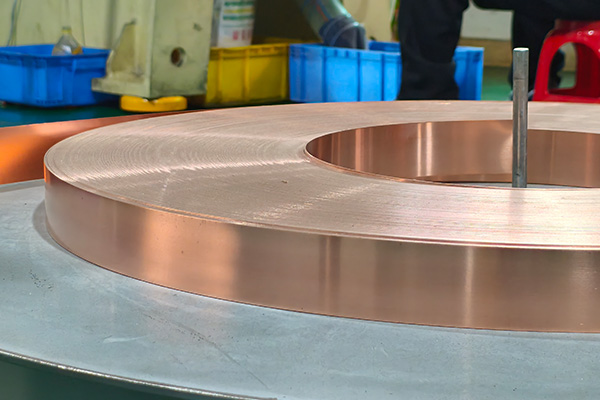

Disc / Flat Commutators

Compact axial designs for space-constrained motors. Planar geometry and surface finishing are managed to spec, supporting smooth brush contact and reliable assembly.

Custom Designs (Per Drawing)

For special geometries or material stacks. We provide drawing-based manufacturing with practical DFM-style feedback when requested, from prototype validation through to stable mass production.

Automotive Motors Commutators

For components such as starter, wiper, HVAC, and actuator motors. Emphasis on consistency, documentation, and traceability to support supplier qualification and ongoing series production.

Power Tools Commutators

Built for high speed and frequent load cycles. Precision turning and balanced construction (where required) help maintain stable commutation under repeated use.

Smart Appliances Commutators

Focused on steady contact surfaces and durability to support quiet operation and long service life in household devices and small appliances.

Robotics Commutators

For motion systems that value precision and repeatability. Tight tolerance control and clean finishes support reliable performance in robotics and actuator applications.

Capabilities & Process

Capabilities & Manufacturing Process

From the first RFQ to shipment, XDC follows a controlled workflow expected by OEM procurement and quality teams:

Drawing & Requirements → Quotation → Tooling (if required) → Prototype → Inspection & Verification → Mass Production → Packaging & Shipping

Throughout the process, we provide practical manufacturability feedback (DFM-style notes where appropriate) without changing your design intent, helping engineering and purchasing move faster with lower risk.

Materials & Construction

Materials & Construction Options

We manufacture according to your specified construction and materials. Typical options include:

Structures: Hook type, Slot type, Disc/Flat designs (as applicable by drawing).

Segments & Insulation: Segment configuration per drawing; insulation systems aligned with your spec.

Copper & Alloys: Grades and purity per BOM requirements.

Joining & Processing: Silver brazing/soldering as specified; machining/turning for commutator faces; dynamic balancing where required.

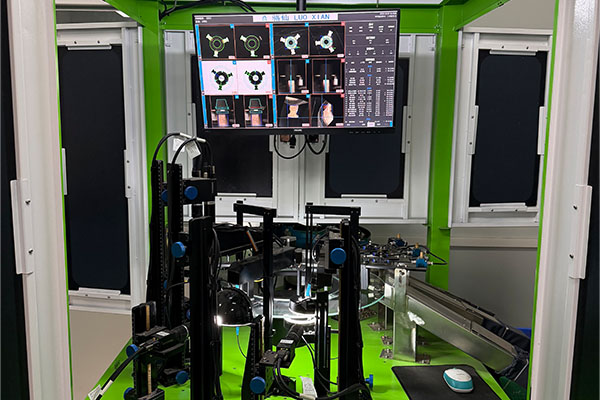

Validation: Dimensional checks, insulation/hi-pot per spec, runout/concentricity where applicable, and documentation upon request.

Quality

Quality Control (ISO 9001)

Production is managed under an ISO 9001 quality system with three layers of control—Incoming Inspection, In-Process Control, and Final Inspection—to stabilize consistency and reduce variance. We support batch traceability, and inspection records are available upon request. Where customers define critical characteristics, our checks can align to those parameters and be included in shipment documents.

Tooling & Low-Volume Orders

Custom commutators usually require tooling. Tooling cost is charged one-time for new designs. For larger volume programs, we can discuss amortization or refund options tied to quantity milestones. Share your expected annual volume and we’ll propose a reasonable plan together with your quotation.

Industries

Industries We Serve

Tell us about your application and annual volume; we’ll advise the optimal commutator structure.

Automotive

Supply-ready manufacturing with documented process control.

Power Tools

Repeatable output for performance-sensitive applications.

Smart Home & Appliances

Production with traceability and inspection records.

Robotics & Motion / Transmission

Support for precision requirements and stable cooperation.

Contact Us

Upload Your Drawing to Get a Quote

Tell us about your project or upload your drawing for a quotation. Please include quantity, material requirements, and any critical characteristics (tolerances, insulation, lifecycle). A sales engineer will review your files and respond with pricing and practical manufacturability notes. NDA available—all documents are handled confidentially.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ

XDC Commutator - FAQ

Welcome to the XDC FAQ page. Here you will find answers to the most common questions regarding our manufacturing processes, ordering details, and quality standards. If you have a question that isn’t listed here, please contact our sales team directly.

Drawing + quantity + material requirement. Include any critical requirements (tolerances, insulation, runtime/lifecycle) in the message.

Yes. We manufacture strictly according to customer drawings and specifications.

Yes. Batch traceability is supported and inspection records are available upon request.

Usually yes for new designs. Tooling is charged one-time; for large volumes, amortization or refund options can be discussed.

Yes. NDA is available upon request before sharing sensitive files.

Blog

Knowledge Center

Our blog content will provide you with a wealth of information and inspiration. They not only reflect our expertise and experience, but also encourage you to explore and discuss relevant topics with us.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…