Starter Motor Commutator Supplier in China

As China’s premier commutator manufacturer, XDC specializes in designing and producing high-precision starter motor commutator solutions for automotive, commercial, agricultural, and industrial applications. Every commutator in starter motor assemblies we deliver is built to strict dimensional, electrical, and material standards to ensure stable cranking performance and long, reliable service.

High-Precision Starter Motor Commutator for Demanding Applications

The starter motor commutator sits on the armature shaft and works with carbon brushes to switch current to the windings. When the engine needs to start, the commutator on starter must withstand high current, high torque, and repeated thermal cycling without deformation, excessive arcing, or surface damage.

XDC engineers each starter commutator with:

- Optimized copper segment geometry for uniform brush contact

- Carefully controlled mica insulation for strong dielectric strength

- Tight concentricity and runout limits to minimize brush bounce and sparking

These are not generic copper rings; they are engineered components tailored to the real electrical and mechanical demands inside a commutator in starter motor assembly.

Starter Motor Commutators by XDC

Precision commutators for brushed starter and small DC motors, including copper and carbon options in multiple diameters and segment counts. Designed for stable brush contact, reliable current switching, and secure coil connections, supporting consistent performance under high-current start conditions.

23.2mm 8-Segment Carbon Commutator

Carbon commutator with 23.2 mm outer diameter and 8 segments. Designed for starter motor armatures, providing stable brush contact and consistent current switching.

5.6mm 5-Segment Starter Commutator

Compact 5.6 mm commutator with 5 segments for small starter motor armatures, supporting stable brush contact and consistent current switching.

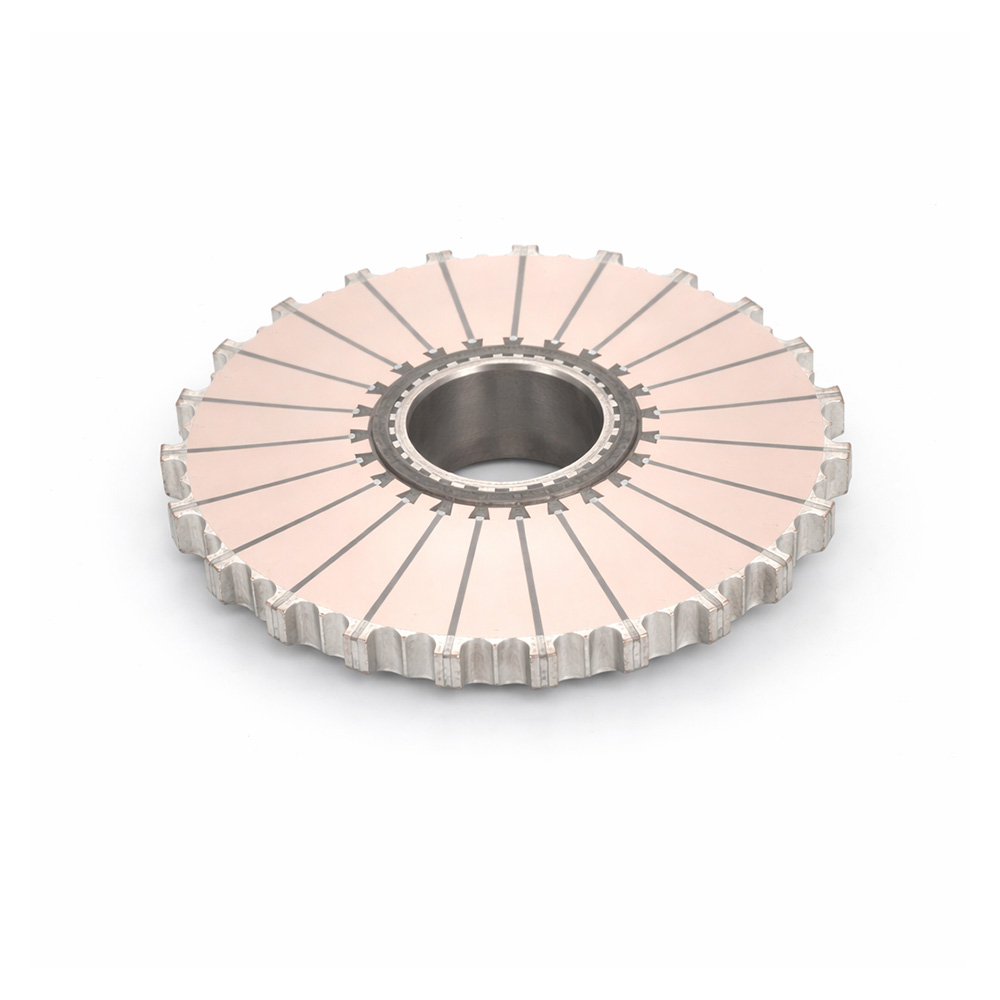

44mm 23-Segment Starter Commutator

44 mm commutator with 23 segments for starter motor armatures. Provides uniform brush track and reliable commutation under high current operation.

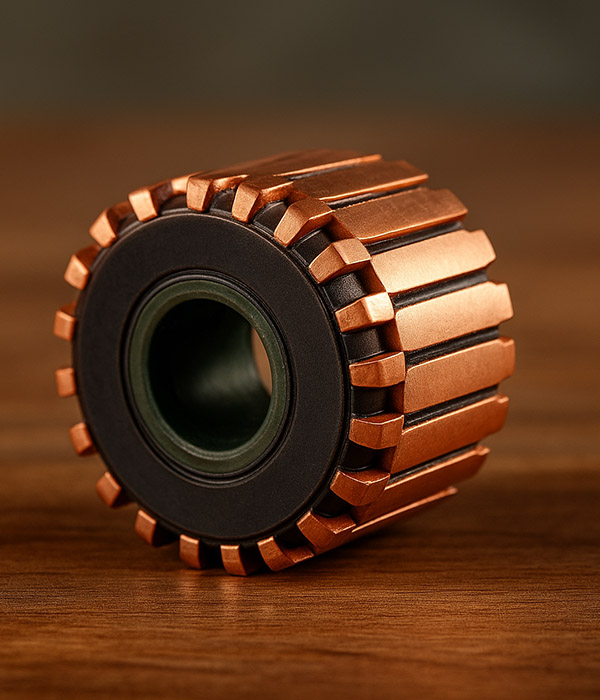

Copper Segmented Starter Commutator

Segmented copper commutator for starter motor armatures. Cylindrical design supports stable brush contact and reliable current switching in high-load starting conditions.

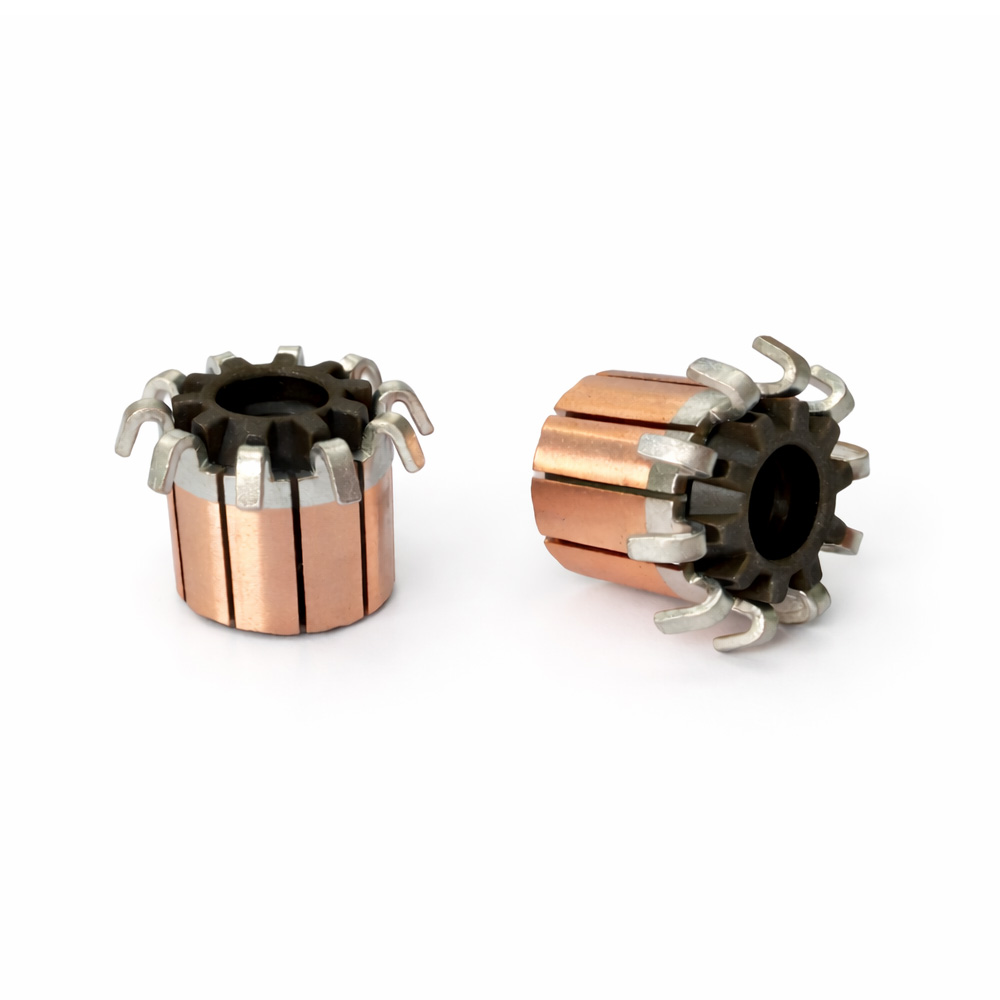

15mm 10-Segment Starter Commutator

15 mm commutator with 10 segments for starter motor armatures. Maintains consistent brush contact and stable commutation for reliable starting performance.

370 Motor Copper Commutator

Compact commutator for 370-size DC motors, with copper segments and molded insulation. Supports smooth brush contact and stable current switching in small motor assemblies.

15.2mm 10-Segment Starter Commutator

15.2 mm commutator with 10 segments for starter motor armatures. Copper segments and hook tabs support secure coil connections, stable brush contact, and reliable commutation.

2.9mm 3-Segment Micro Commutator

2.9 mm commutator with 3 segments for miniature brushed DC motors. Compact copper design supports stable brush contact and consistent commutation in small assemblies.

Manufacturing Process – How XDC Builds a Reliable Commutator in Starter Motor

To guarantee consistent performance of the starter motor commutator, we combine automated production lines with experienced engineers:

Copper bar forming and segment preparation

Copper bars are formed, cut, and machined under controlled conditions. Segment dimensions are checked to ensure uniform contact around the commutator on starter circumference.

Stacking, molding, and curing

Copper segments are positioned with precise insulation gaps. Mica and resin are applied to form the body of the starter commutator, then cured for strength and thermal stability.

Turning, grinding, and undercutting

The outer surface of the starter motor commutator is turned and ground to final size. Mica undercutting is carried out with controlled depth so brushes track correctly without shorting across segments.

Surface finishing and cleaning

Final finishing achieves a smooth, uniform track where brushes can form a stable film. Cleaning removes any particles that could cause early arcing or a starter motor commutator bad spot.

Technical Specifications & Quality Standards

To showcase our factory’s professionalism and product quality, XDC defines clear, measurable standards for each starter motor commutator we produce:

- Segment material: high-purity copper, controlled for hardness and conductivity

- Insulation system: high-grade mica and resin, tested for insulation resistance and heat stability

- Dimensional tolerances: strict limits on outer diameter, bore, and length to match armature and housing precisely

- Runout & concentricity: controlled to very low values to keep the commutator on starter running smoothly at speed

- Surface finish: fine turned and burnished to promote fast brush film formation and reduced wear

Every batch of starter commutator passes:

- 100% visual inspection for surface defects and mechanical damage

- Electrical tests for continuity between segments and insulation to shaft/core

- Random sampling for more detailed checks such as runout and balance, according to customer requirements

Why Choose XDC for Your Starter Commutator Needs?

Specialist Manufacturer in China

XDC focuses on commutators. We are not simply reselling parts; we design and manufacture the starter motor commutator in our own facilities. This gives customers:

• Direct technical communication with the engineering team

• Fast response for drawing changes or new commutator on starter projects

• Stable quality and supply, managed in one place

Customization and Engineering Support

We can customize the commutator in starter motor for:

• Different segment counts and diameters

• Special shaft bores, keyways, and chamfers

• Brush grades and holder designs that match your full starter system

Our engineers will review your drawings or samples and propose the best starter commutator solution for your torque, current, and space requirements.

Strict Quality Management

XDC follows rigorous internal quality procedures from raw materials to final inspection. We work with many customers who require automotive-level standards, and we understand the documentation and consistency they expect from a starter motor commutator supplier.

Contact Us – Work with XDC, China’s Premier Commutator Manufacturer

Looking for a reliable partner for starter motor commutator production?

Contact XDC with:

- Your drawings of the commutator in starter motor

- Required quantities

- Special requirements for packaging, marking, or testing

Our sales and technical teams will review your needs, propose a suitable starter commutator design, and provide a clear quotation and lead time.

Let XDC be your trusted commutator factory in China for every commutator on starter project you launch.

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Function of Commutator in Starter Motor & Customer Concerns

The function of commutator in starter motor systems is to switch the DC current in and out of different armature windings as the rotor turns. The starter motor commutator works together with the brushes to convert battery power into mechanical rotation with high torque. A precisely machined commutator on starter ensures that current flows smoothly, arcing is controlled, and the starter delivers consistent performance.

A starter motor commutator bad spot usually appears as a single area where the starter fails to turn or turns only if the shaft position changes slightly. It can be caused by uneven segment height, contamination, or poor surface finish. XDC minimizes this risk by applying strict machining tolerances, controlled undercutting, and careful cleaning, so each commutator in starter motor achieves a smooth, uniform track for the brushes.

Yes. If you provide drawings or a physical sample, XDC can measure the starter motor commutator and reproduce the commutator on starter with equivalent or improved materials and tolerances. We can also suggest design optimizations if you experience specific field issues, such as excessive arcing or difficult installation.

To speed up the quotation and design process, please prepare:

- Technical drawing or sample of your commutator in starter motor

- Required quantities and annual demand

- Performance or testing requirements for the starter commutator (insulation tests, runout limits, packaging, etc.)

Our team will then give targeted technical suggestions and pricing.

Yes. XDC engineers can support you during prototype testing and validation of the starter motor commutator in your motor. If you encounter abnormal wear, noise, or a potential starter motor commutator bad spot, we will help analyze the cause and adjust the design or process conditions where needed.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…