Slip Ring Manufacturer in China

XDC is a leading commutator manufacturer in China, now bringing the same precision engineering to every slip ring solution we deliver. As a rotary electrical connector, a slip ring transmits power and signals between stationary and rotating parts, allowing continuous 360° motion with no cable twisting, no tangled harnesses, and stable performance in demanding equipment.

From compact capsule units to high-current and subsea designs, XDC designs and manufactures both commutator and slip ring products for industrial, automotive, energy, and defense customers worldwide.

Slip Rings We Have Manufactured

Buying directly from the XDC factory means competitive pricing and rapid prototyping. We offer a comprehensive range of electrical rotary joints designed to meet the rigorous demands of global markets.

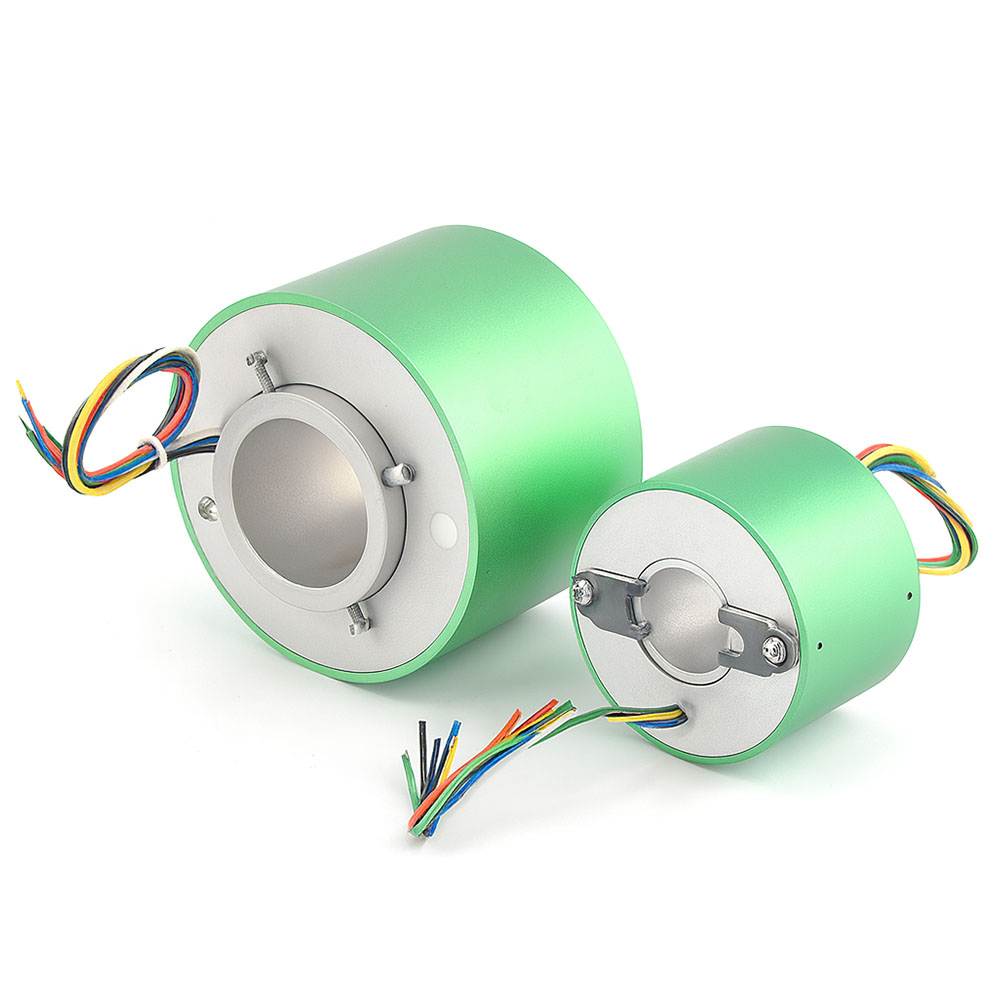

Through-Bore Series

Features a central hole for routing hydraulic or pneumatic lines. Ideal for industrial automation and rotary tables.

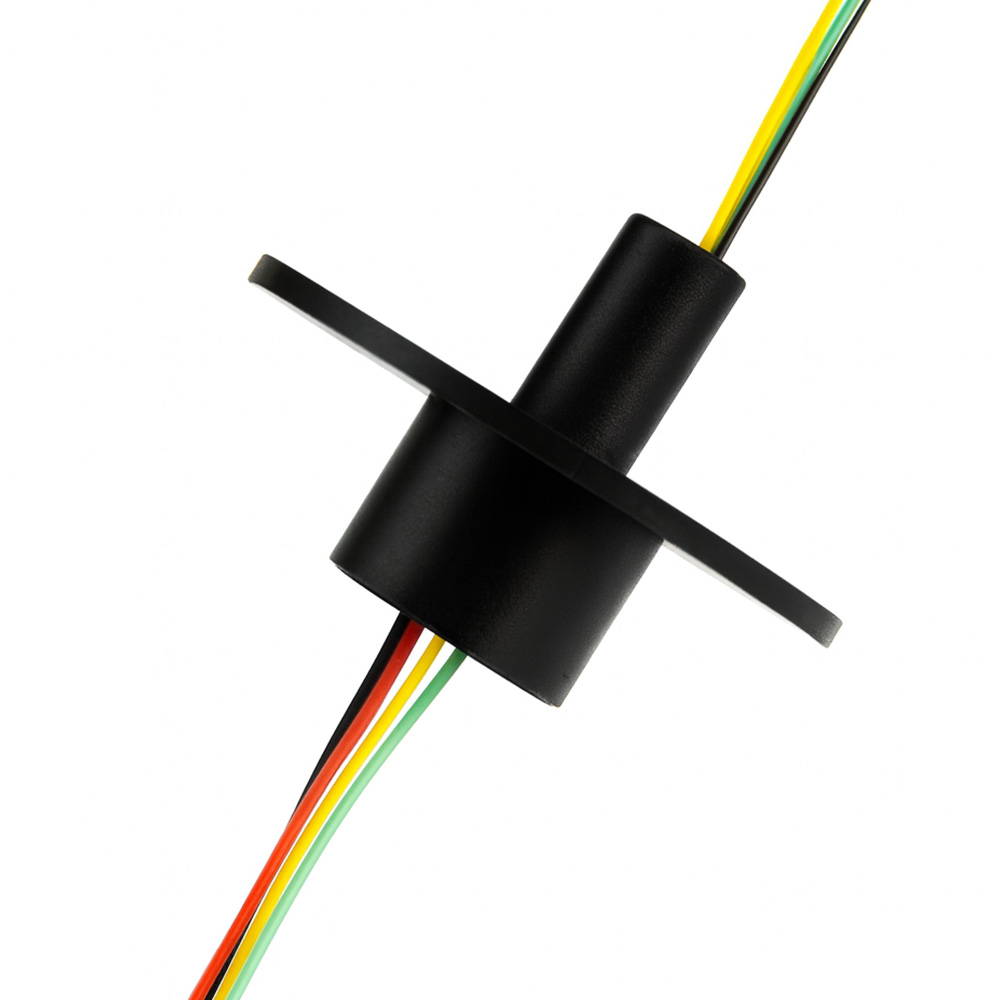

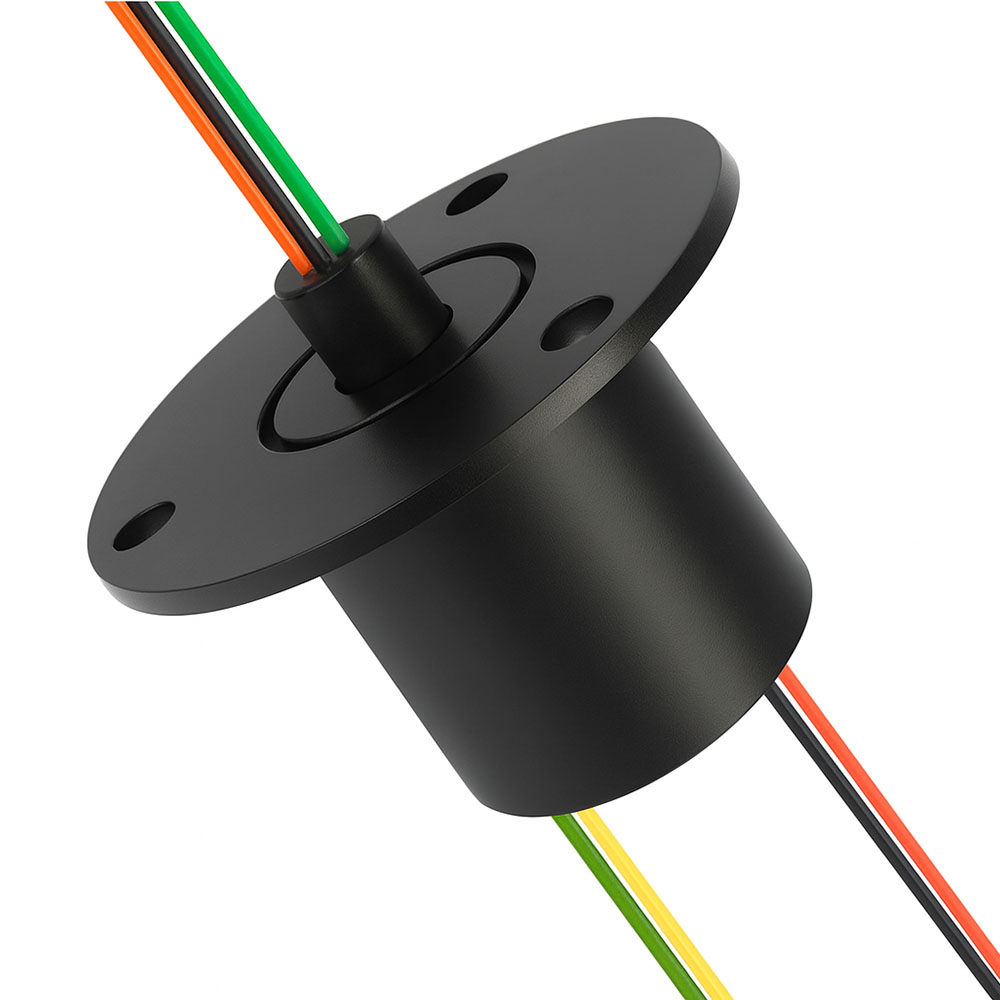

Miniature Capsule Series

Compact design with low torque. Perfect for CCTV security cameras, medical equipment, and small instruments.

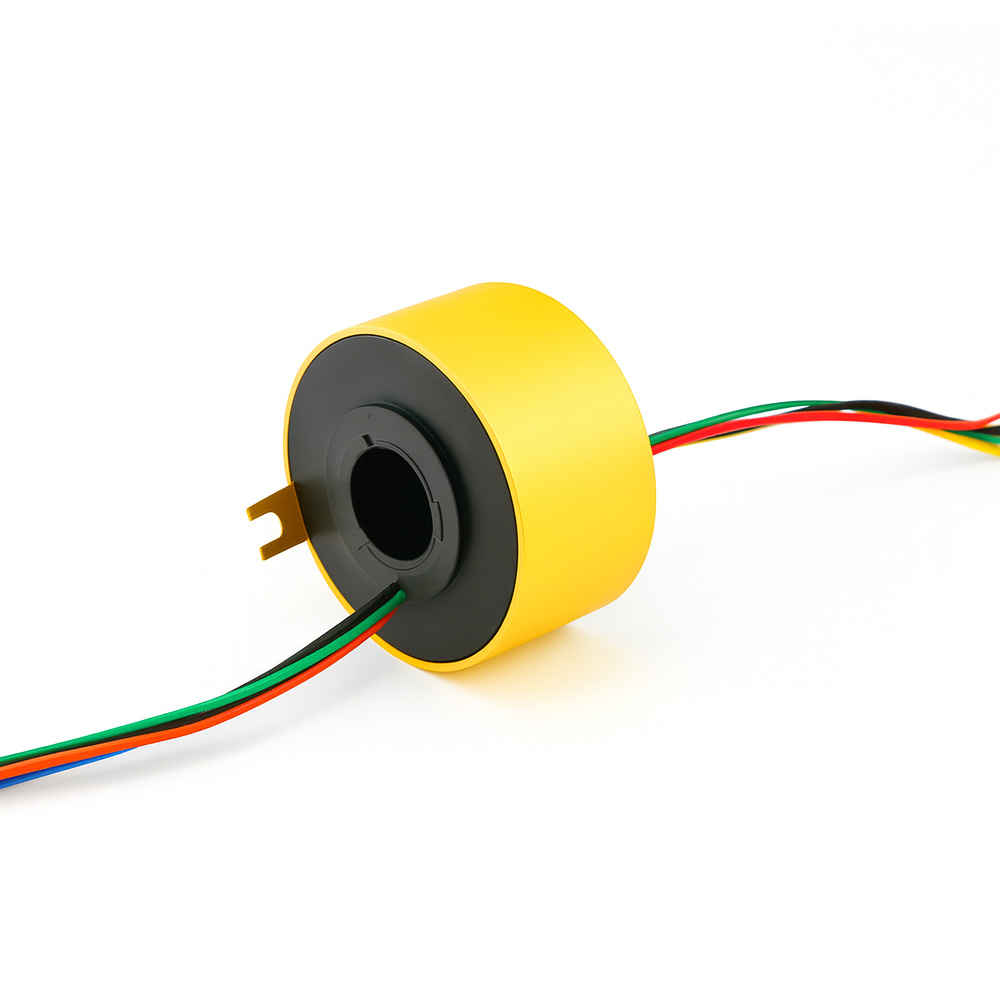

Aluminum Alloy Standard Series

Rugged aluminum housing providing excellent durability and interference protection for general machinery.

Separate / Split Slip Rings

Rotor and stator are separated to fit into height-restricted spaces. Designed for precision instruments and gyroscopes.

High-Speed / Brushless Connectors

High-speed rotation with zero maintenance. Ideal for sensitive signal transfer and laboratory equipment.

Robotics & Automation Rings

Specialized slip rings designed for robot arms and packaging systems, ensuring stable power and signal transmission.

Heavy Duty / High Power Series

Robust solutions designed to handle high current and harsh environments. Suitable for construction machinery and wind turbines.

Custom OEM/ODM Solutions

Can’t find what you need? We engineer custom slip rings tailored to your specific size, circuit, and housing requirements.

Manufacturing Process – How XDC Builds a Reliable Commutator in Starter Motor

To guarantee consistent performance of the starter motor commutator, we combine automated production lines with experienced engineers:

Copper bar forming and segment preparation

Copper bars are formed, cut, and machined under controlled conditions. Segment dimensions are checked to ensure uniform contact around the commutator on starter circumference.

Stacking, molding, and curing

Copper segments are positioned with precise insulation gaps. Mica and resin are applied to form the body of the starter commutator, then cured for strength and thermal stability.

Turning, grinding, and undercutting

The outer surface of the starter motor commutator is turned and ground to final size. Mica undercutting is carried out with controlled depth so brushes track correctly without shorting across segments.

Surface finishing and cleaning

Final finishing achieves a smooth, uniform track where brushes can form a stable film. Cleaning removes any particles that could cause early arcing or a starter motor commutator bad spot.

Standard Platforms & Mechanical Configurations

XDC provides a comprehensive portfolio of slip ring solutions designed as standardized building blocks that can be tailored to the specific voltage, current, and speed requirements of automation and motion systems. Our range addresses diverse mechanical constraints, ensuring reliable power and signal transmission for any physical configuration.

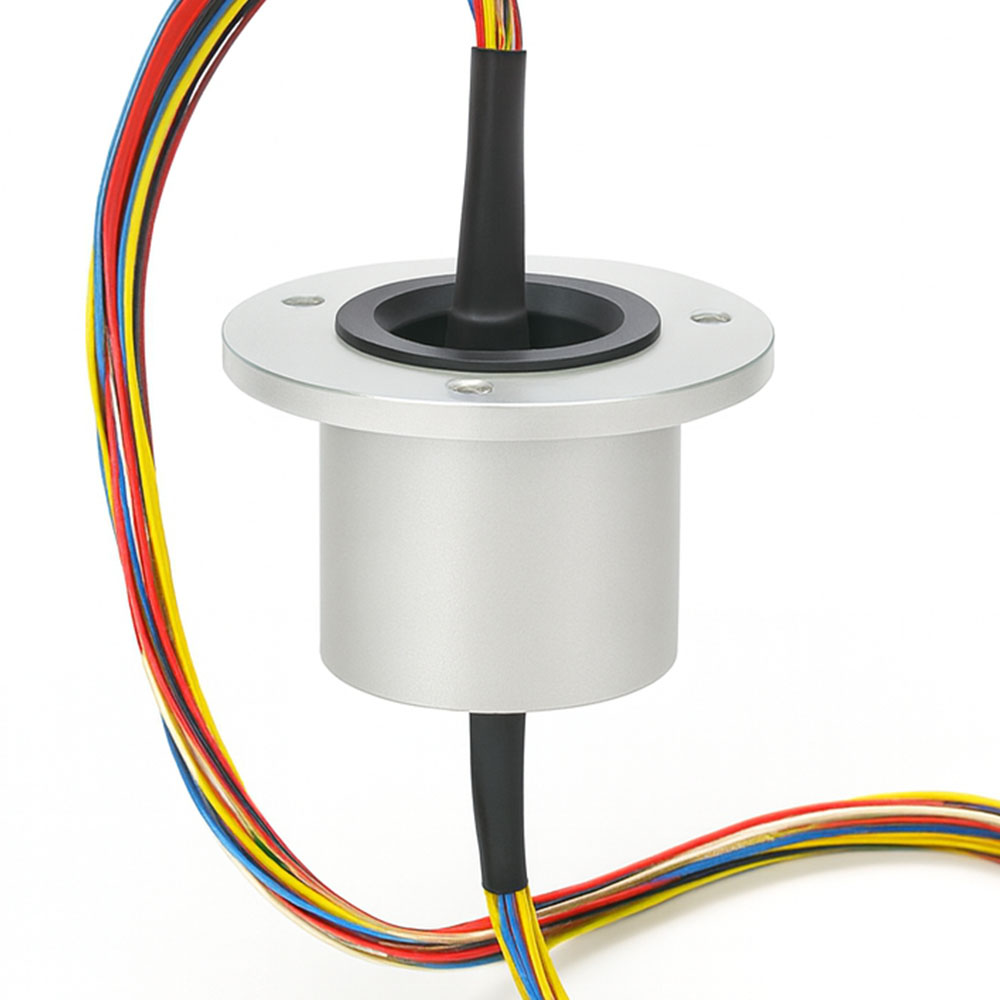

For space-constrained applications, we offer Compact Capsule Slip Rings featuring sealed bodies and gold-on-gold contacts. These units support up to 2 A per circuit and are ideal for precision instruments, medical devices, and servo feedback. When higher performance is required, our High-Speed Capsules maintain stable transmission for USB and Gigabit Ethernet signals at speeds ranging from 6,000 to 10,000 rpm, perfect for gimbals and sensors.

For machinery requiring central routing for shafts or hydraulic lines, our Through-Bore (Hollow-Shaft) models offer bore sizes from 25.4 mm to 80 mm. These robust units handle up to 600 V and are widely used in packaging machines and rotary tables. Alternatively, where vertical height is strictly limited, our Pancake Slip Rings utilize a flat disc design to provide multiple channels in an ultra-low profile, serving radar pedestals and indexing plates without compromising on circuit count or reliability.

High-Performance, Heavy-Duty & Integrated Solutions

Beyond standard mechanical forms, XDC specializes in advanced electrical capabilities and solutions for harsh environments. To support Industry 4.0, our Ethernet and Data Slip Rings integrate power with 1000Base-T or fiber optic rotary joints, ensuring networked equipment like robotic arms and PTZ cameras remain connected. For complex aerospace and defense needs, we offer High-Density models capable of packing up to 150 mixed channels into a compact 50 mm housing.

For heavy industry, our High-Current and High-Voltage assemblies are engineered for extreme loads. These modular units support currents from 10 A up to 1,000 A per ring and voltages up to 6,000 V, making them essential for wind turbines, welding plants, and cranes. We also cater to hazardous locations with Marine and ATEX-ready models, featuring IP66+ sealing and explosion-proof designs suitable for subsea ROVs and chemical plants.

Finally, XDC offers holistic Commutator and Slip Ring Solutions. By controlling the entire manufacturing chain, we design matched hybrid systems for motors and generators. Our engineering team optimizes contact geometry, brush wear, and thermal management, ensuring that both the commutator and slip ring components work in harmony to deliver maximum service life and minimal maintenance.

Why Choose Us for Slip Ring & Commutator Manufacturing

Technical advantages

• Deep experience as a top commutator producer in China

• Dedicated R&D on slip ring contact materials and brush technology

• Full in-house machining, plating, molding, and assemblyElectrical testing for insulation resistance, contact resistance, and noise

Application support

• Customization of bore size, circuit count, and cable type

• Support for mixed power, analog, digital, Ethernet, and fiber optic channels

• Co-engineering for combined alternator commutator and rotary connector systemsGuidance on mounting, wiring, grounding, and shielding

Quality and logistics

• ISO-based quality systems and traceable materials

• End-of-line tests on every shipped slip ring unit

• Flexible MOQs for OEM and replacement ordersGlobal shipping from our Chinese manufacturing base

Typical Slip Ring Applications by Industry

Industrial automation & robotics

• Rotary tables and indexers

• Packaging lines and pick-and-place systems

• Robot joints and grippers needing power and I/O over 360° rotation

• Rotary tables and indexers

• Packaging lines and pick-and-place systems

• Robot joints and grippers needing power and I/O over 360° rotation

Energy & power generation

• Wind turbine hubs and pitch control systems

• Cable reels on yard cranes and mining equipment

• Specialized alternator commutator and slip ring sets in custom generators

• Wind turbine hubs and pitch control systems

• Cable reels on yard cranes and mining equipment

• Specialized alternator commutator and slip ring sets in custom generators

Security & imaging

• PTZ CCTV cameras and domes

• Radar and tracking antennas

• Medical CT scanners and rotating imaging tables

• PTZ CCTV cameras and domes

• Radar and tracking antennas

• Medical CT scanners and rotating imaging tables

Marine, offshore & hazardous areas

• Subsea ROV tethers and winches

• Offshore cranes, carousels, and turret systems

• ATEX-rated mixers and bulk handling systems

• Subsea ROV tethers and winches

• Offshore cranes, carousels, and turret systems

• ATEX-rated mixers and bulk handling systems

Contact Us for Slip Ring and Commutator Projects

Ready to specify a new slip ring or upgrade an existing alternator commutator system? XDC’s engineering team in China is ready to help.

- Send us your electrical requirements (current, voltage, circuits)

- Attach your mechanical drawing or rough slip ring diagram

- Let us know target quantities and delivery schedule

We will respond with a practical, cost-effective commutator and slip ring proposal tailored to your machinery.

Get in touch with XDC today and let our slip ring and commutator experts support your next rotating equipment project.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

Slip Ring FAQ

The function of slip ring in AC generator systems is to transfer the generated alternating current from the rotating armature or rotor to the external stationary circuit. In an AC machine, a slip ring provides a continuous circular contact surface, so the output leads do not twist as the rotor turns. This is different from an alternator commutator in older designs, which segmented the contact surface to rectify the output.

A slip ring works by using stationary brushes pressed against a rotating ring. The brush connects to the fixed wiring, and the ring connects to the rotating wiring. As the shaft turns, the ring carries current around its circumference while the brush makes a sliding electrical contact, maintaining power or signal flow. This simple principle makes a slip ring the most practical rotary electrical connector for continuous 360° operation.

Yes. Each XDC slip ring model ships with a clear slip ring diagram showing:

- Circuit numbering and color codes

- Rotor and stator side wiring

- Mechanical dimensions, mounting details, and bore sizes

- Recommended grounding and shielding points

We can also provide 2D and 3D files so your engineering team can integrate the slip ring diagram directly into your CAD environment.

In many modern alternators, there is a clear distinction between commutator and slip ring components:

- A slip ring provides a continuous circular contact for AC power or field excitation.

- An alternator commutator uses segmented bars for rectification or special control tasks in some legacy or custom designs.

XDC can design both the alternator commutator and the associated slip ring assembly so they share compatible materials, brush forces, and insulation, extending the life of the complete generator.

Yes. Our hybrid slip ring models combine separate rings for power, control signals, and 100Base-T or 1000Base-T Ethernet. Proper shielding and twisted-pair routing inside the rotary connector keep data integrity high while power rings handle motor, brake, or heater loads. For very demanding bandwidth, we can integrate a fiber optic rotary joint in the same housing.

When selecting a slip ring, consider:

- Maximum current per circuit and total system current

- Voltage level and insulation requirements

- Number of independent circuits (power, control, fieldbus, Ethernet, video)

- Shaft size or bore needed, plus mechanical envelope and speed

- Environment (temperature, IP rating, vibration, marine or ATEX)

Share this information with XDC and we will recommend a standard model or a customized slip ring and alternator commutator package if needed.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…