Purpose of Split Ring Commutator

In almost every school diagram of a DC motor or DC generator there’s a little label that quietly says “split ring commutator”… and the textbook just moves on. Yet this tiny copper ring is the reason a DC motor keeps spinning in one direction and a DC generator produces DC instead of AC. No split ring, no DC machine as you know it.

Table of Contents

TL;DR – What the Split Ring Commutator Actually Does

- In a DC motor:

- Reverses the current through the rotating coil every half turn (every 180°).

- Keeps the torque in the same rotational direction, so the motor doesn’t “rock back and forth” but spins continuously.

- In a DC generator:

- Reverses the connections of the rotating coil to the external circuit every half turn.

- Flips each negative half-cycle of the induced AC, so the output voltage is always in the same direction (pulsating DC).

- Mechanically:

- Acts as a rotary switch made of two copper halves.

- Works together with carbon brushes to provide a sliding electrical connection between the spinning armature and the outside world.

1. Meet the Split Ring Commutator

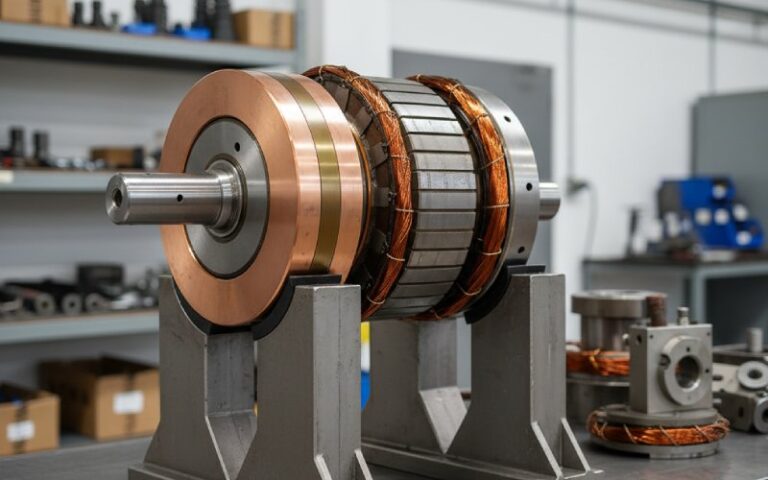

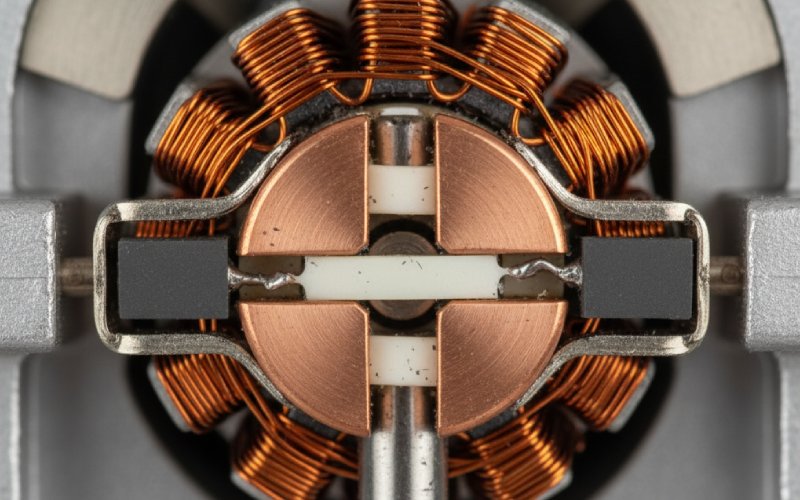

Imagine slicing a copper ring into two semicircles and putting them on the motor shaft with a tiny gap and insulation between them. Each half-ring is welded to one end of the armature coil. Two stationary carbon brushes press gently on these segments.

As the shaft rotates, each brush glides from one copper half to the other. That simple action—brushes swapping from one half to the other—is what quietly reverses the current through the coil at just the right time and keeps everything behaving like “proper DC”. The whole assembly of split ring + brushes is what we call the commutator.

At a Glance: How a Split Ring Commutator Is Built

- Shape: A ring split into two (or more, in real machines) insulated copper segments.

- Material: Copper segments, insulated from each other and from the shaft with mica or other insulation.

- Position: Mounted on the rotor/armature shaft, rotating with the coil.

- Connections:

- Each segment connects to one end of the armature winding.

- Stationary carbon brushes press on the outside of the ring.

- Bonus fact: In real DC motors and generators, you often have dozens of narrow segments and multiple coils to smooth the torque and the output voltage.

2. Why DC Motors Need a Split Ring Commutator

Think about a single rectangular coil in a magnetic field between a north and south pole. When current flows through the coil:

- One side of the coil feels a force up.

- The opposite side feels a force down.

Those two forces form a turning couple, so the coil starts rotating. But after half a turn, the sides have swapped places. If the current direction in the coil stayed the same, the forces would flip and the torque would now act in the opposite direction. The motor would simply rock between two positions instead of spinning.

The split ring commutator saves the day by reversing the current exactly when the coil passes the vertical position (every half revolution). Because both the coil orientation and the current direction reverse together, the direction of the torque stays the same, and the rotor keeps turning smoothly.

What Happens During One Full Turn (Motor Storyboard)

- At 0° (starting position):

- Coil is horizontal.

- Side A carries current “into the page”, side B “out of the page”.

- Using Fleming’s left-hand rule, side A feels an upward force, side B downward – torque is, say, clockwise.

- Approaching 90°:

- Torque is still in the same direction, but its magnitude drops (forces act closer to the pivot).

- Coil whizzes through the position where forces temporarily give almost no turning effect.

- Exactly at 90° (vertical):

- The brushes lose contact with one pair of segments and connect to the other pair.

- This flips the current in the coil — side A now has current opposite to what it had before.

- From 90° to 180°:

- Coil has physically flipped, and the current has flipped too.

- Result: the torque is still clockwise. The motor doesn’t reverse; it continues in the same direction.

- After 180°:

- The same process repeats: every half turn, the commutator reverses the current again, always keeping the torque direction consistent.

So the purpose in a DC motor is:

“Reverse the coil current every half turn so that the motor’s torque never changes direction.”

3. Purpose of Split Ring Commutator in DC Generators

Now flip the story: instead of feeding electricity in to get motion out, we drive the shaft mechanically (with a turbine, engine, hand crank, etc.) and get electricity out. As the armature coil cuts through the magnetic field, an alternating EMF is induced in the coil (positive half-cycle, then negative half-cycle).

If we connected this coil straight to an external circuit with slip rings, we’d get a standard AC output. But DC generators are supposed to deliver voltage that doesn’t reverse direction.

The split ring commutator solves this by reversing which end of the coil connects to the positive and negative output terminals every half turn. That means whenever the EMF in the coil would have gone negative, the connections are swapped so that the external circuit still sees the same polarity. The result is pulsating DC: the voltage rises and falls, but it never goes below zero.

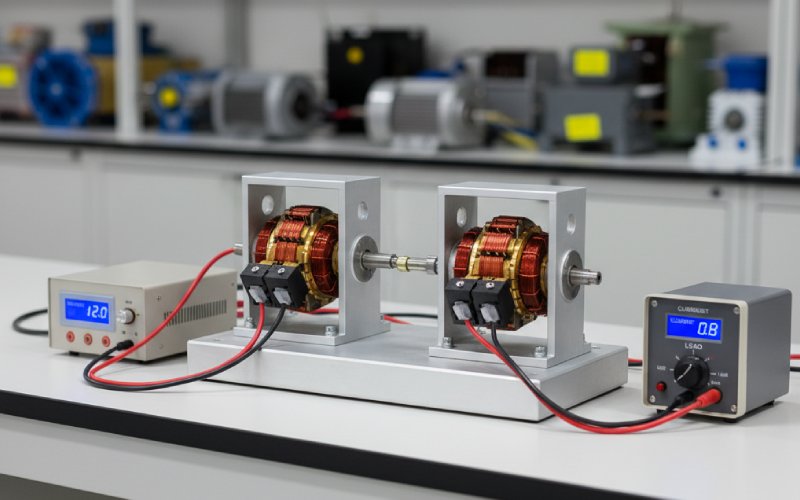

Step-by-Step: Generator View of the Split Ring

- Mechanical input: The armature is spun through a magnetic field.

- Induced AC in the coil: Inside the coil, the EMF alternates as it rotates (a sine wave if the speed is constant).

- Commutator switch: Every 180°, the split ring reverses which coil end connects to which brush.

- External output: The negative half-cycles get flipped upright — the load sees unidirectional pulses (DC).

So in generators, the purpose is basically: “Turn AC induced in the rotating coil into DC supplied to the external circuit.”

4. Split Ring vs Slip Ring – Clearing the Confusion

Students (and plenty of adults) often mash these two together, but they’re different creatures.

- A split ring is part of a commutator, designed to reverse current and produce DC-like behavior in motors and generators.

- A slip ring is designed to transmit power or signals continuously to a rotating part, without changing polarity — ideal for AC machines.

Comparison Table: Split Ring vs Slip Ring

| Feature / Basis | Split Ring Commutator | Slip Ring |

| Main job | Reverse current direction in the rotor coil | Provide continuous electrical connection to a rotating part |

| Typical use | DC motors and DC generators | AC generators, some AC motors, rotating sensors |

| Physical form | Copper ring split into 2+ insulated segments | One or more continuous rings (unbroken) |

| Effect on external voltage | Converts induced AC to pulsating DC | External circuit sees the same AC as in the coil |

| Current direction in load | Always unidirectional (though varying in size) | Alternating – changes direction with each half-cycle |

| Companion parts | Carbon brushes make & break contact with different segments | Carbon brushes or metal contacts slide on continuous rings |

| Typical waveform at output | Pulsating DC, smoothed further with more segments/coils | Sine-like AC, depending on machine design |

Quick Memory Hooks

- “SPLIT ring” → SPLIT the polarity → used where you want DC.

- “SLIP ring” → SLIP power through continuously → used where you want AC or uninterrupted signals.

- If the diagram shows a ring with a gap → think commutator / DC.

- If the ring looks complete and smooth → think slip ring / AC.

5. Real-World Design Notes (Beyond the Textbook Diagram)

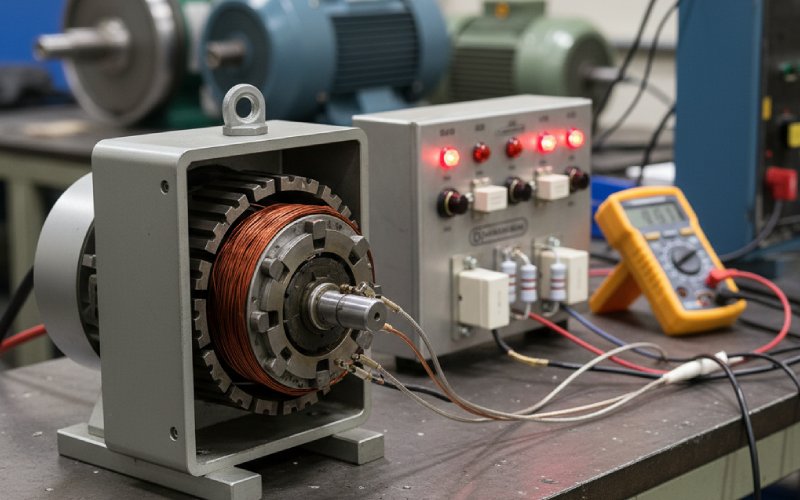

In real machines, the split ring commutator isn’t just a cute two-part ring. Industrial DC motors and generators use many narrow copper segments with multiple coils. This multi-segment design makes the torque smoother and the DC output closer to a flat line. It also spreads the current over several segments to reduce heating and wear.

Engineers also worry about sparking, brush wear, and noise. Every time a brush moves from one segment to the next, there’s a tiny interruption and reconnection of current. The geometry of the commutator, the material of the brushes, and even the shape of the coil windings are tuned so that commutation happens around the moment when the induced EMF in that coil is minimal, cutting down on arcing and energy loss.

Design Trade-offs the Split Ring Introduces

- Pros

- Enables simple, robust speed control for DC motors (by changing supply voltage or field strength).

- Gives direct DC output in generators without needing electronics.

- Time-tested, widely understood, and relatively cheap for moderate power levels.

- Cons

- Brushes and commutator segments wear over time → maintenance needed.

- Sparks can cause electrical noise and limit use in explosive atmospheres.

- At very high speeds or very high currents, mechanical commutators become a weak link, which is why many systems now use brushless DC motors and electronic switching instead.

6. How to Remember the Purpose of the Split Ring Commutator (For Exams and Real Life)

If you strip away all the jargon, a split ring commutator is just a self-timed rotary switch that flips the direction of current in the rotor coil every half turn. That flipping:

- Keeps the motor turning in one direction by keeping torque direction constant.

- Keeps the generator’s output pointing in one direction by flipping negative voltage swings upright.