Newman Motor Commutator Manufacturer | XDC China

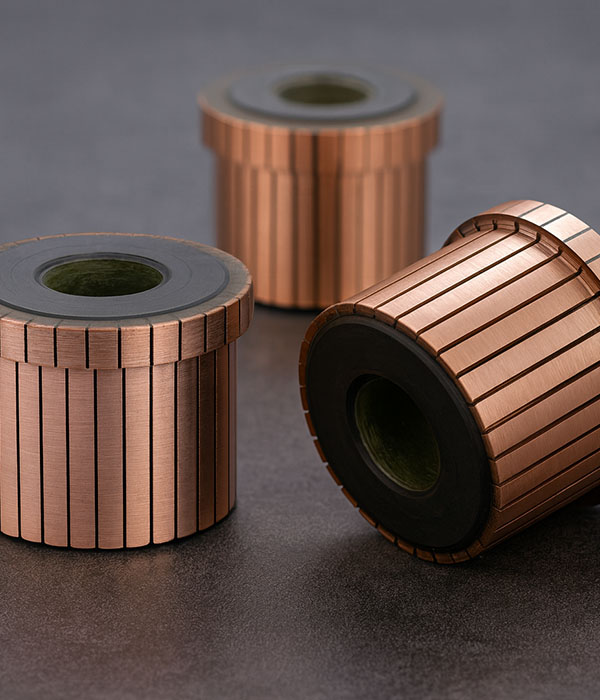

As China’s premier commutator manufacturer, XDC specializes in the precise design and production of the Newman motor commutator for single-coil pulse motors, research machines, and advanced brushed DC prototypes.

Our focus is simple: stable high-voltage operation, consistent timing, and long brush life, backed by controlled test data and strict factory quality standards.

Newman Motor Commutator Solutions for Demanding Pulse Motor Projects

XDC engineers your Newman motor commutator to withstand the unique demands of large inductive coils, permanent magnet rotors, and pulsed DC operation.

Our production designs are validated on test benches that simulate:

- Supply voltages up to 600–650 V DC

- Transient coil spikes up to approx. 1,500 V generated by inductive collapse

- Operating speeds in the 200–500 RPM range typical of large pulse motors

- Duty cycles around 25–30% with two commutation events per revolution

This means your Newman motor commutator arrives ready to work in harsh, high-inductance environments where ordinary small DC commutators cannot cope with back EMF spikes and arcing.

Core Specifications of the XDC Newman Motor Commutator

Each XDC Newman motor commutator is tailored to your drawing, but our standard technical scope includes:

Segment layout

Two main copper segments arranged 180° opposed for classic Newman-style polarity reversal. Optional multi-segment versions for refined timing and pulse shaping

Segment geometry

Typical reference design: 4 mm copper segment width with 3 mm insulating gap for clean make/break behavior. Concentricity and run-out controlled to tight tolerances for smooth brush contact

Electrical capability

Designed for DC bus voltages up to 600–650 V. Transient spike handling tested against ~1,500 V coil spikes under controlled lab conditions

Mechanical capability

Smooth operation around 230–500 RPM in large pulse motor rigs. Support for permanent magnet rotor shafts and standard bearing interfaces

Precision machining

- CNC machining and turning of the commutator body for accurate diameter and roundness

- Controlled clearance between segment and insulation to reduce commutator arcing

- Careful finishing to achieve a smooth contact surface for the carbon brush set

Professional assembly

- Accurate positioning of copper segments, slip rings (if required), and shaft interface

- Strict control of brazing or welding quality at segment connections to armature winding terminals

- Full balance check of the rotating assembly to minimize vibration at operating speed

Life and performance testing

- Comparative tests show that optimized segment geometry and surface finishing can multiply free-spin run-down time by more than four times compared with older designs, demonstrating reduced friction and contact losses.

Long-cycle switching tests under pulsed DC verify that the Newman motor commutator maintains stable performance under repeated inductive spikes.

Why Choose Us for Your Newman Motor Commutator Needs

When you choose XDC, you are working with a dedicated commutator manufacturing plant, not a trading company.

Focused expertise

• Decades of experience with dc commutator motor components

• Deep understanding of pulsed DC motor behavior, back EMF, and inductive spike conditions

• Proven ability to adapt commutator designs for large single-coil and permanent magnet rotor applications

Stable quality & traceability

• Clearly documented production routes for every Newman motor commutator batch

• Incoming inspection of copper, insulation, and shaft materials

• 100% final checks on concentricity, insulation resistance, and appearance

Flexible customization

• OEM service for different shaft diameters, rotor lengths, and brush layouts

• Optional slip rings, special brush angles, and custom segment patterns for specific timing windows

• Cooperative engineering support to match the commutator to your coil inductance, resistance, and desired duty cycle

Reliable delivery from China

As China’s premier commutator manufacturer, XDC is structured for stable mass production as well as small-batch development runs, giving you a single, dependable source for every Newman motor commutator requirement.

Custom Engineering for Newman Motor Commutator OEM Orders

For OEM and laboratory customers, we offer full engineering support around the Newman motor commutator itself, including:

- Selection of segment count and segment angle to match your rotor position and torque curve

- Brush grade and brush pressure recommendations to reduce wear and minimize arcing

- Insulation system selection (mica or resin systems) to withstand high-frequency inductive spikes

- Design coordination with your armature winding and coil design so that commutation timing, back EMF and torque are aligned with your performance goals

Whether you are building a prototype pulse motor or scaling up a production line, XDC can supply a Newman motor commutator that fits seamlessly into your design and process.

Contact Us – Talk to XDC About Your Newman Motor Commutator

Ready to move your project forward with a reliable Newman motor commutator supply partner?

Contact XDC, China’s premier commutator manufacturer, with your drawings or specification list. Our engineering and sales teams will review your requirements, recommend the most suitable Newman motor commutator configuration, and provide a clear quotation and lead time.

XDC – Professional Commutator Manufacturing for Your Newman Motor Commutator Needs.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Newman Motor Commutator Supply

Yes. We support small pilot runs for new projects. Once your design is confirmed, we can move to mass production using the same validated process for your Newman motor commutator.

We typically require basic drawings or specifications: shaft size, outer diameter, number of copper segments, operating voltage, expected RPM, and brush arrangement. The more detail you provide, the more precisely we can optimize your Newman motor commutator.

Absolutely. If you already have a working motor, we can evaluate your current commutator and recommend changes in segment geometry, brush angle or insulation system to enhance stability, reduce arcing, and extend service life of the Newman motor commutator.

Our factory operates under strict internal process control, and we can align with your required standards for material traceability, insulation resistance, and dimensional tolerances. Every Newman motor commutator is tested for basic electrical and mechanical integrity before shipment.

Yes, we can provide sample Newman motor commutator units for fitment and initial testing, followed by series production after your approval.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…