Motor Commutator Cleaner: Keeping Contact Honest Without Killing the Commutator

Cleaners are not magic. They are controlled damage: you spend a little copper, a little brush life, to buy back stable current, acceptable film, and a predictable maintenance window. Used with intent, they extend motor life; used casually, they quietly shorten it.

Table of Contents

The awkward truth: manuals say “don’t abrade”, technicians still do

If you read enough OEM manuals and motor guides, you see a pattern. Many large DC motor documents say things like “never clean the commutator with abrasive cloth or solvents; preserve the patina; use only a dry cloth and then a grindstone for running-in.”

Yet field practice in workshops, on production lines, and in hobby benches is full of emery paper, commutator stones, rubber sticks, contact cleaner, even toothbrushes and alcohol.

Both worlds are right in their own context. The manual is written for motors where commutator replacement is expensive and downtime planning is deliberate. Your reality might be a hand drill, a vacuum motor, a small DC drive, or a traction motor that must run today. So a “motor commutator cleaner” is really a compromise tool. You accept small, local damage now to avoid large damage later.

The question is not “which cleaner is best”. It is “what problem am I solving, in this exact motor, with this level of risk”.

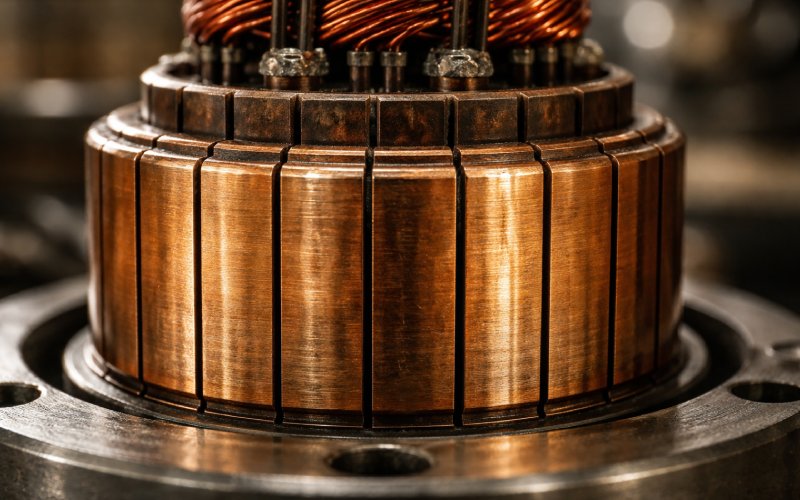

The main families of motor commutator cleaner

You already know what a commutator and brush film are, and you have read at least one official maintenance guide. So instead of definitions, here is how practitioners actually classify cleaners in their heads.

There are very soft approaches: dry lint-free cloth, compressed air at sensible pressure, maybe a mild solvent like isopropyl alcohol or a branded contact cleaner. These mainly lift dust, oil, and loose carbon without reshaping copper.

Then there are shaped abrasives: commutator stones, garnet paper, micro-abrasive rubber sticks, “commutator cleaner” blocks used in RC motors and small appliances. They cut copper, score the surface slightly, and reset the film when it has gone patchy or burned.

And finally there are two dangerous groups: generic emery cloth with aluminum oxide, and aggressive solvents applied with little thought. EASA specifically warns against aluminum-oxide emery on commutators because the conductive particles embed and promote arcing. Some OEMs warn that strong solvents destroy the patina they actually rely on for stable running.

Most “motor commutator cleaner” products sit somewhere between a commutator stone and a gum eraser. Micro-abrasive, shaped to match curvature, easy to hold, forgiving enough that an impatient technician doesn’t instantly ruin the rotor.

Comparison of commutator cleaning options

| Cleaner type | Relative aggressiveness | Typical use case | Main risk if misused | Notes |

| Dry lint-free cloth and low-pressure air | Very low | Routine DC motor inspection, brush change, light dust removal | Pushing debris into slots, leaving trapped carbon | OEM-friendly; preserves patina when film quality is already good |

| Contact cleaner + toothbrush / swab | Low to moderate | Small motors, armatures out of housing, removal of oil and light tracking | Washing solvent into windings or bearings, stripping film too often | Works well on hand tools and vacuum motors when drying is controlled |

| Micro-abrasive rubber “commutator cleaner” stick | Moderate | Hobby motors, RC motors, small appliances, spot cleanup of bars | Over-rounding, creating uneven segments, debris left inside motor | Feels safe, but still cuts copper; treat as a real abrasive |

| Garnet paper or commutator stone | Moderate to high | Seating new brushes, correcting minor ridges and high bars in service DC motors | Excessive material removal, tapering the commutator, film reset too often | Widely recommended when used at low or zero voltage and with care |

| Cleaning carbon brush (engineered to scrub) | Low to moderate | Online cleanup of slip rings or commutators when downtime must be short | Accelerated brush wear, possible uneven film if loading is uneven | Convenient when you cannot pull the rotor or mount in a lathe |

| Aluminum-oxide emery cloth | High (and conductive) | Historically used for “quick clean” in the field | Embedded conductive grit, chronic arcing, rapid surface damage | Generally better to avoid for modern DC machine maintenance |

This is not a moral ranking. It is simply the trade space. You choose where to stand.

Matching the cleaner to the motor and the fault

Take three motors: a 550-size hobby DC motor, a universal motor from a vacuum cleaner, and a large industrial DC drive.

On the hobby motor, the armature is cheap. The commutator is small, the load cycles are severe, and the user often accepts that the motor is a consumable. A micro-abrasive commutator cleaner stick, a drop of contact cleaner, maybe a very light polish, all make sense. You accept extra wear; you mostly care about immediate performance and slightly longer life than “run it until it sparks and dies”.

On the vacuum motor, you are in the middle. The copper has already seen dust, hair, overloads. Often the best result comes from a mechanical clean using alcohol or contact cleaner with a soft brush, removing fragments and copper dust, and only then deciding whether any abrasive is still needed.

On the large DC drive, the commutator is expensive and usually has a designed brush film that should not be reset for trivial reasons. Here, the first “cleaner” is almost always a dry cloth, gentle vacuum or air, and inspection. If the surface really needs correction, maintenance teams use commutator stones, lathe turning, or very controlled garnet paper work at low or zero voltage.

Now overlay fault types:

If the issue is just dust and light discoloration, a dry clean or mild solvent is enough. If there is light streaking, tracking, or copper flakes around the brush path, you might combine mechanical cleaning with brush inspection and grading checks.

If bars are ridged, notched, or there is visible burning, your “commutator cleaner” is really a machining plan. Abrasive blocks become a stop-gap to limp to the next outage, not the main fix.

This is why a single, generic “motor commutator cleaner” product rarely covers every motor on site. The product is one tool; the real decision is about acceptable risk in that machine.

A realistic cleaning sequence (small and medium motors)

Forget the pristine step-by-step diagrams for a moment and think about what actually happens on a bench.

A technician pulls the motor, often already dirty, and blows out loose dust with low-pressure air or a small vacuum nozzle, trying not to drive debris under the windings. Then the armature is exposed, and the commutator gets a visual check: color of the film, groove depth, bar edges, raised mica, any signs of lifted segments.

If the film looks mostly uniform and copper is not badly scored, they will often start with a cloth and maybe alcohol or contact cleaner. The goal is simple: remove oil, carbon smear, and any conductive mud around the edges, without touching the geometry.

Only if the surface still looks suspect does a dedicated commutator cleaner come out. On a hand drill or vacuum motor, that might be a rubber stick or fine abrasive applied while the rotor is rotated by hand, trying to keep pressure even and avoid flat spots. Short passes, frequent inspection, no drama.

For DC motors where brushes are being replaced, the cleaning step blends into seating. Sandpaper or a commutator stone may be used with the motor at rest or at very low voltage, so that the brush face and commutator match radius. The “cleaner” is now part of achieving proper contact geometry, not just making copper shiny.

Finally, everything is cleaned again: loose abrasive dust is removed, slots are checked so they are not packed with debris, and the motor is reassembled. Run-in under light load is as important as the cleaning itself. A good cleaner sets the stage; the film rebuild during running decides whether that cleaning was worth doing.

Mistakes that slowly destroy commutators

One common mistake is treating patina as dirt. Many OEMs want a thin, even film on the commutator; stripping it back to bright copper on every minor service keeps the motor in permanent “fresh wound” mode, with higher wear and more risk of sparking. A commutator cleaner should reset the surface only when film quality is clearly hurting performance. Not every visit.

Another mistake is using the wrong abrasive. Aluminum-oxide emery cloth looks harmless, feels like “just fine sandpaper”, and it is cheap. But conductive particles embed in the copper and create tiny hot spots under the brushes. EASA’s guidance is unambiguous about avoiding it on commutators and slip rings. Garnet paper, commutator stones, and purpose-made cleaning sticks exist for a reason.

Third, flooding the area with solvent and letting gravity decide where it goes. Contact cleaner down the slots, into the windings, into porous insulation or bearings, is not cleaning, it is relocation. Drying time becomes unpredictable, and residues may remain where you never look. Many small-motor guides show toothbrush plus controlled spray for a reason: local action, minimal soak.

Fourth, cleaning under full load. A quick scrub on a live commutator with an abrasive block might feel efficient, but it mixes mechanical damage with electrical stress. Brush bounce, transient arcing, and uneven copper removal combine into a surface that looks neat but behaves poorly. Short, low-voltage runs to distribute new brush film are far less destructive.

Finally, ignoring the brush. If you need a commutator cleaner every time you inspect a motor, the problem is rarely “dirty copper” alone. Brush grade, spring pressure, electrical settings and load profile all control film quality. A cleaner can’t fix a brush that is wrong for the job.

Specifying commutator cleaners in a maintenance plan

Instead of buying a random “motor commutator cleaner” stick whenever there is trouble, it is usually better to make cleaner choice part of your maintenance standard.

You decide which motors are “no-abrasive except by written exception”. Usually the large DC drives, traction motors, anything where commutator replacement is painful or regulated. For these, your default kit is lint-free cloth, vacuum or low-pressure air, perhaps a recommended commutator stone with documented grit, and a clear procedure that matches the OEM literature.

You decide which motors are moderate risk. Universal motors in tools and appliances, mid-size DC motors where the rotor can be removed and replaced at reasonable cost. Here you standardize on one or two cleaning methods: for example, approved contact cleaner, a specific micro-abrasive stick, and limits on how often geometry-altering work is allowed before you consider rewinding or replacement.

And you accept that some small motors are near-disposable. For them, a simple commutator cleaner product that restores performance for another season is reasonable. You still avoid conductive abrasives, but you worry less about copper loss and more about quick turnaround.

Logging matters. Each time a commutator cleaner is used, noting date, method, observed condition, and resulting performance turns guesswork into trends. Combined with brush wear data and inspection notes, it becomes very clear which cleaners give you stable operation and which just create short, noisy wins.

Short wrap-up

A motor commutator cleaner is not just a block, a stick, or a spray. It is a decision about how much copper, brush life, patina, and downtime you are willing to trade for better contact today. When you match the cleaner to the motor type, the fault, and the long-term plan for that machine, cleaning stops being a ritual and turns into controlled maintenance. The manuals stay mostly right, your field practice stays honest, and the commutator lives long enough that you hardly think about it between scheduled stops.