Is a Slip Ring a Commutator? The Honest, Deep-Dive Answer

If you’ve ever stared at a motor diagram and thought “Wait… is this slip ring just a fancy commutator?” you’re absolutely not alone. Even manufacturers and textbooks sometimes blur the language, which is why this topic feels more confusing than it should.

Let’s untangle it properly, in human terms, without hand-wavy definitions.

Table of Contents

The 30-Second Answer

A slip ring is not a commutator in normal electrical-engineering language — but a commutator is a very specific, specialized kind of slip-ring-like device.

- Slip rings

- Continuous metal rings

- Provide a steady electrical connection between stationary and rotating parts

- Used mainly where you just need to transfer power or signals while something spins (AC generators, wind turbines, rotating platforms, CT scanners, radar antennas, etc.)

- Continuous metal rings

- Commutators

- Built from segmented copper bars, not a smooth ring

- Work as a mechanical switch/rectifier that reverses current direction every half turn in DC machines

- Used in DC motors & DC generators (and universal motors), where we need unidirectional torque or DC output

- Built from segmented copper bars, not a smooth ring

- Language twist

- Some vendors and older texts call a commutator a kind of “special slip ring,” or even use the phrase “slip ring commutator”, especially in older machine descriptions.

- But modern references (and exam mark schemes) treat “slip ring” and “commutator” as distinct terms and say the names are not interchangeable.

- Some vendors and older texts call a commutator a kind of “special slip ring,” or even use the phrase “slip ring commutator”, especially in older machine descriptions.

So if you’re answering an exam, writing a spec, or talking to an engineer, the safe, professional answer is:

No, a slip ring is not a commutator — they are different components with different jobs.

First: What Exactly Is a Slip Ring?

At heart, a slip ring is the hardware equivalent of a rotating extension cord. Its entire personality is:

“Let something spin freely while I keep the electricity or signals flowing.”

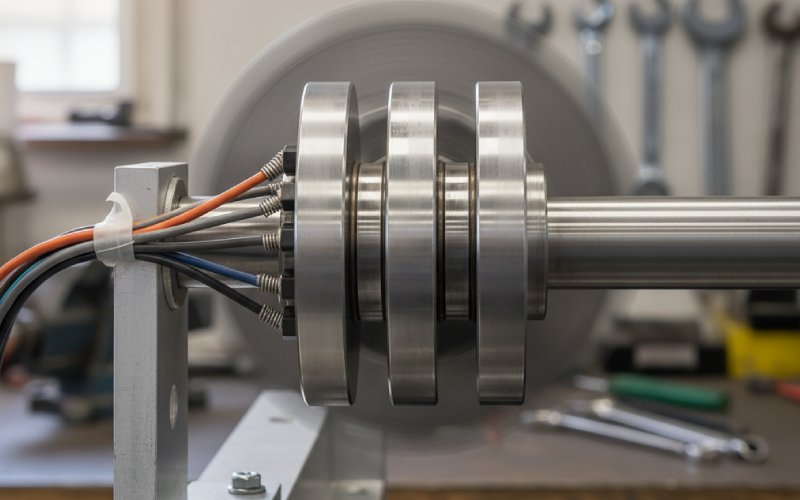

In a typical design, you have one or more metal rings mounted on the rotating shaft, and stationary brushes (graphite or metal) that lightly rub on those rings. As the shaft spins, that sliding contact lets current or signals move between stationary and rotating parts without the cable twisting up and breaking.

You’ll see slip rings anywhere you need continuous rotation + continuous connection:

- Wind turbine nacelles sending generator power while yawing

- Large AC generators feeding current into rotor field windings

- CT scanners spinning a massive X-ray gantry around a patient

- Radar antennas and rotating camera platforms

Because the ring is continuous (no gaps), the current does not reverse just because the rotor turned — the slip ring is “dumb”: it just connects.

Slip Ring in a Nutshell

- Provides continuous electrical path between stationary and rotating sides

- Can carry power, control signals, data, or mixed channels

- Ring surface is smooth and unbroken (for each circuit)

- Often lives in AC machines or any rotating system where direction of current doesn’t need to change at the brushes

And What Is a Commutator?

A commutator is more like a rotating mechanical rectifier + switch. Instead of a smooth ring, you have a cylinder made up of many copper segments, each insulated from its neighbours. Brushes sit on that segmented cylinder.

As the rotor turns, each brush successively makes contact with different segments. The way the coils are wired to those segments means that, from the point of view of the external circuit, the commutator is periodically flipping the direction of current in each rotor coil, such that the external current remains in one direction (DC) or the torque stays in one direction.

This is the reason DC motors and DC generators can work at all without electronic rectifiers.

In other words: slip ring = “let things spin while connected,” commutator = “spin, and also cleverly switch the connections in sync with rotation.”

Commutator in a Nutshell

- Used primarily in DC motors, DC generators and universal motors

- Segmented copper ring (lots of little bars) + brushes

- Actively reverses current in armature coils every half turn

- From outside, acts as a mechanical rectifier, turning armature AC into DC

So… Is a Slip Ring Actually a Commutator or Not?

Here’s where terminology gets slippery (pun very much intended).

From a very broad, hand-wavy standpoint, a commutator is a kind of rotating contact system between brushes and a rotor — you could loosely call it a “special type of slip ring that also switches current.” Some manufacturers even say exactly that: a commutator is a specialized slip ring, with segmented metal pieces instead of a solid ring, designed explicitly to reverse current.

But mainstream references (like textbooks and Wikipedia) are stricter:

- They define slip rings as continuous rings for transmission of power/signals between stationary and rotating structures.

- They define commutators as rotary electrical switches specialized for DC machines, with segmented construction that reverses current.

- They explicitly say that some people use the term “commutator” for slip rings, but stress that this is technically incorrect and that the terms are not interchangeable.

So the practically useful, engineer-safe way to answer the question “Is a slip ring a commutator?” is:

- In exam / textbook / standards language:

▶️ No. Slip rings and commutators are treated as different components. - In loose, vendor-marketing language:

▶️ You might see phrases like “slip ring commutator” or claims that a commutator is a specialized type of slip ring. Technically they’re emphasising the rotating contact function, but mixing the terms can confuse people. - Best practice:

▶️ Use “slip ring” when you mean a continuous ring connector,

▶️ Use “commutator” when you mean a segmented switching device in a DC machine.

Head-to-Head: Slip Ring vs Commutator

To go deeper than most competing articles, let’s make this comparison very explicit — not just “continuous vs segmented,” but what that actually does to your machine design.

Comparison Table

| Aspect | Slip Ring | Commutator | Why It Matters |

| Physical construction | One or more continuous metal rings with stationary brushes rubbing on them | Segmented copper cylinder; each segment insulated, wired to armature coils | Visual inspection instantly tells you which you have. |

| Core function | Maintain continuous electrical connection while allowing unlimited rotation | Periodically reverse current in rotor windings; act as mechanical rectifier | Slip ring = connector; commutator = connector plus timed switching. |

| Typical machine type | AC generators, slip-ring induction motors, rotating platforms, scanners, wind turbines | DC motors, DC generators, universal motors | Helps you identify what you’re looking at in real equipment. |

| Current behaviour | Does not inherently change direction; passes AC or DC as-is | Designed to flip direction each half turn so external current stays DC | Decides whether your machine output is AC or DC and how torque behaves. |

| Naming in exams/textbooks | Called simply “slip rings” for AC machines | Called “split-ring commutator” or just “commutator” in DC machines | Using the wrong word is a classic exam trap. |

| Wear & maintenance | Wear mostly from friction and contamination; no switching sparks in normal use | More prone to sparking and copper wear because of switching; often needs more maintenance | Affects lifetime, service intervals, and safety planning. |

| Conceptual relationship | General rotary connector | A specialized rotating connector that also switches, often described as a specialized slip ring | Explains why the terms get mixed yet should stay distinct in careful usage. |

In short: all commutators involve sliding contacts like slip rings, but not all sliding-contact devices are commutators.

Quick Ways to Tell Them Apart in the Lab (or a Drawing)

When you’re standing in front of a motor/generator or looking at a schematic, here’s how to quickly decide whether you’re dealing with slip rings or a commutator:

- Look for segmentation

- Smooth circular ring per circuit? → Slip ring.

- Many little copper bars around the shaft with visible insulation between them? → Commutator.

- Smooth circular ring per circuit? → Slip ring.

- Check the machine type

- Nameplate says “DC motor,” “DC generator,” or “universal motor”? Expect a commutator.

- Large AC generator or slip-ring induction motor? Expect slip rings on the rotor.

- Nameplate says “DC motor,” “DC generator,” or “universal motor”? Expect a commutator.

- Watch the current behaviour (on a scope)

- If brushes are feeding AC straight in or out, and nothing about the ring reverses it, you’re looking at a slip ring.

- If the rotor windings see their connections swapped twice per revolution so the external circuit sees DC, that’s a commutator.

- If brushes are feeding AC straight in or out, and nothing about the ring reverses it, you’re looking at a slip ring.

- Listen and smell (yes, really)

- Slip rings tend to run more quietly electrically (less arcing) when designed and maintained well.

- Commutators in old or overloaded DC motors can hiss, crackle, or show visible sparking, and you may smell hot carbon or ozone from brush wear.

- Slip rings tend to run more quietly electrically (less arcing) when designed and maintained well.

Why AC and DC Machines Ended Up With Different Rings

To really internalise the difference, it helps to zoom out to the physics.

In a simple rotating coil in a magnetic field, the voltage induced in the coil naturally alternates (AC) as the coil rotates. That’s true regardless of whether you ultimately want AC or DC from the machine.

- AC machines (slip rings)

- They’re happy to let the induced voltage stay AC.

- The rotor often just needs a supply for the field winding (in synchronous machines) or is designed so torque works fine with AC currents.

- So we don’t need to flip or rectify anything at the brushes — we just need a rotating connection.

- Result: continuous slip rings are perfect.

- They’re happy to let the induced voltage stay AC.

- DC machines (commutators)

- We don’t want AC at the terminals; we want DC, or at least a unidirectional torque.

- Instead of using electronics, early designers used a mechanical trick: re-wire which coil ends the brushes are touching every half turn, synchronised to the rotation.

- That mechanical re-wiring is the commutator in action — a rotary switch that silently “rectifies” the armature AC into DC.

- We don’t want AC at the terminals; we want DC, or at least a unidirectional torque.

This historical path is why:

- Slip rings dominate where AC and continuous connection are fine.

- Commutators dominate older DC tech, now increasingly replaced by brushless DC + electronics, which eliminate mechanical commutation altogether.

Design Implications You Actually Feel

- Slip rings → easier to design for high speed and mixed signals (with the right construction), but you must manage wear and noise.

- Commutators → integrate both connection and switching, but come with more wear, sparking, and maintenance, so many modern systems avoid them when possible.

Design & Selection Tips (If You’re Specifying Hardware)

Beyond passing exams, you may actually need to choose between technologies or talk to vendors. Here’s a more practical perspective than most “difference” articles offer.

In real projects, you’d normally:

- Choose a slip ring when:

- You have an AC machine or any rotating platform and simply need to route power, control, Ethernet, fieldbus, or sensor signals across a rotating interface.

- You’re retrofitting or designing wind turbines, packaging machines, radar dishes, cable reels, or medical imaging systems.

- You want low electrical noise and can pick from modern forms like pancake, capsule, high-speed, or even wireless slip rings.

- You have an AC machine or any rotating platform and simply need to route power, control, Ethernet, fieldbus, or sensor signals across a rotating interface.

- Choose a commutator when:

- You’re stuck with or deliberately using a DC motor or DC generator that needs mechanical commutation.

- You’re repairing legacy equipment where changing to brushless tech isn’t economical.

- You’re stuck with or deliberately using a DC motor or DC generator that needs mechanical commutation.

When speaking with suppliers, it’s smart to have a mini-checklist:

- Clarify: “I need a slip ring (continuous ring) for AC/rotating signals, not a DC commutator,” especially when language barriers exist.

- Specify channels, current, voltage, signal types, speed, environment (dust, moisture, vibration).

- Ask for expected life, brush material, and maintenance intervals – very important for both slip rings and commutators.

Common Misconceptions & Exam Traps

A lot of online answers (and even some teachers) create confusion. Here are the big myths:

- “Slip ring commutator” = slip ring

- The phrase appears in older or less precise literature, but in modern teaching, it’s clearer to treat “slip ring” and “commutator” separately.

- The phrase appears in older or less precise literature, but in modern teaching, it’s clearer to treat “slip ring” and “commutator” separately.

- Slip ring vs split-ring

- In many school-level physics questions, they compare “slip ring” vs “split-ring commutator.”

- A split ring is literally a ring cut into two halves (or more) → that is the commutator in a simple DC motor diagram.

- In many school-level physics questions, they compare “slip ring” vs “split-ring commutator.”

- “They both just connect rotating parts, so they’re basically the same.”

- Yes, both are sliding contacts between a rotor and brushes.

- But only one of them (the commutator) is deliberately wired to reverse current and “rectify” it; the slip ring just passes whatever you feed it.

- Yes, both are sliding contacts between a rotor and brushes.

- “Slip rings are only for AC and commutators only for DC.”

- Broadly correct in machine context (AC motors/generators use slip rings; DC machines use commutators).

- But slip rings themselves can carry AC or DC — they don’t care. It’s the system that’s typically AC.

- Broadly correct in machine context (AC motors/generators use slip rings; DC machines use commutators).

Knowing these traps makes your exam answers sharper and your technical writing clearer.

FAQ: Short, Human Answers

Q1: In one sentence, is a slip ring a commutator?

No – in standard engineering usage, a slip ring is a continuous rotary connector, while a commutator is a segmented rotary switch that reverses current in DC machines; they look similar from far away but do different jobs.

Q2: Why do some sources call a commutator a kind of slip ring?

Because both use brushes rubbing on rotating conductive surfaces, some authors treat “slip ring” as a very general category; but modern references explicitly warn that the terms should not be used interchangeably to avoid confusion.

Q3: If I see “slip ring motor,” does it have a commutator?

No – a “slip ring motor” is typically an AC induction motor with slip rings on the rotor to connect external resistors or control circuits, not a DC commutator.

Q4: Can I replace a commutator with a slip ring?

Not directly. A slip ring cannot perform the current-reversing/rectifying function a commutator provides; you’d need to redesign the system (e.g., add electronic rectifiers and change the motor topology).

Q5: What’s the safest rule of thumb for naming?

If you’re dealing with AC machines or generic rotating connections, say “slip ring.” If it’s a DC machine that needs current reversal, say “commutator.” That one habit alone keeps your documentation and conversations clear and professional.