Industrial Commutator

An industrial commutator is the rotary electrical switch on a DC motor or DC generator that reverses current in the armature winding and allows smooth torque in one direction. In real plants, the industrial commutator is still the heart of countless brushed DC motors in heavy-duty applications where high starting torque, precise speed control and robustness are critical.

Wherever brushed DC motors deliver from 10 kW up to 5000 kW, XDC industrial commutators are engineered to provide stable commutation, low sparking and extended carbon brush life.

Industrial Commutator Manufacturer in China

At XDC, we focus on one thing and do it exceptionally well: the industrial commutator that keeps your DC and traction motors running reliably in the toughest conditions.

As an industrial commutator company based in China, XDC combines deep engineering know-how with flexible production. Whether you need a single replacement unit for an urgent breakdown or a long-term supply partner for a full motor range, we design and manufacture commutators that match your drawings, your performance targets and your budget.

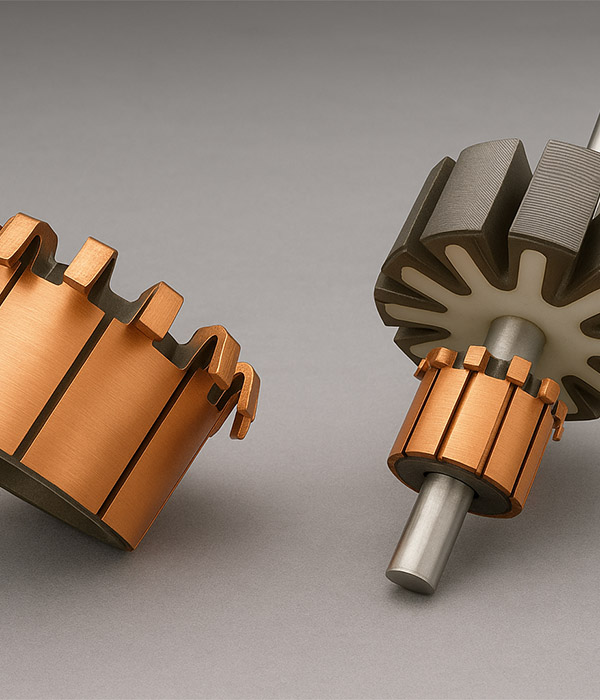

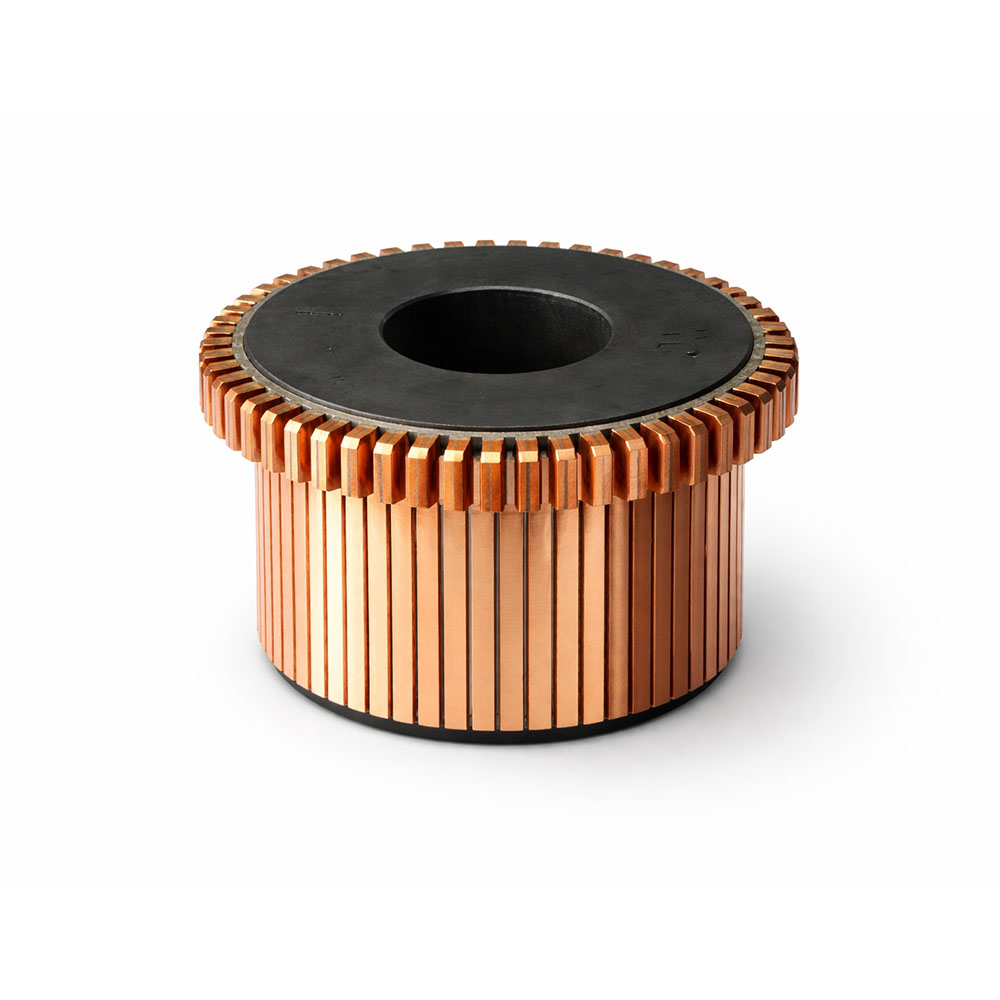

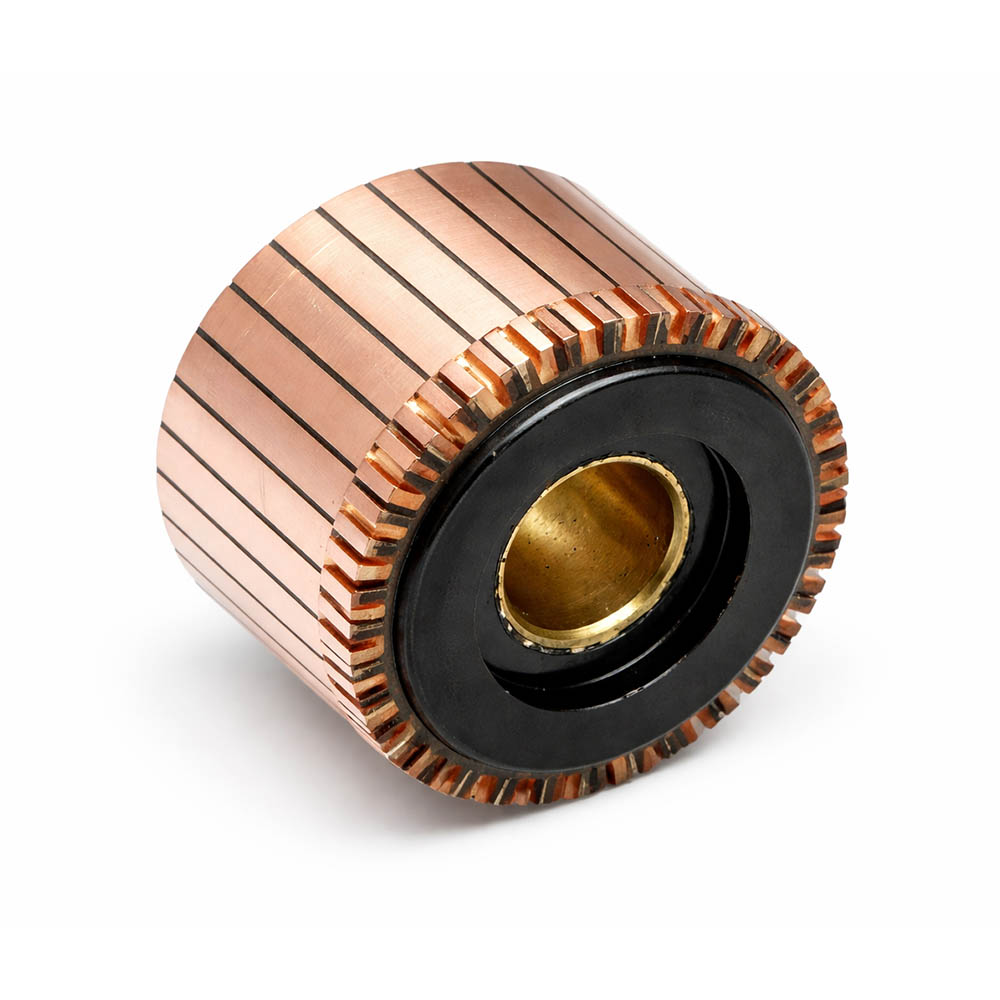

Industrial Commutator Manufactured by XDC

View XDC’s industrial-grade commutators, built to withstand the rigors of heavy-duty machinery. We are committed to manufacturing components that strictly follow your specs, starting with validation pieces before initiating large-scale runs. Assess our durable designs in this section to see our capability, and directly send us your drawings to get a quote.

31-Segment Industrial Commutator

The specific 31-bar configuration minimizes electromagnetic harmonics and reduces bar-to-bar voltage stress. With a 25.5mm OD, this high-density design prevents resonance and arcing in precision industrial motors.

57-Segment Industrial Commutator

The high-density 57-bar configuration optimizes voltage distribution, significantly reducing the risk of flashover. Built with a robust 95.4mm OD, it delivers smooth power transmission for large DC motors.

17-Segment Commutator

Engineered with a prime 17-segment configuration, this unit effectively suppresses magnetic harmonics and cogging torque. It ensures smooth rotation and vibration-free performance for specialized industrial motor windings.

36-Segment Industrial Commutator

Featuring a high-density 36-bar design on a 36.5mm OD, this unit optimizes current distribution. It reduces localized heating at the brush interface, extending maintenance intervals for continuous-duty motors.

Testing and Quality Control from a Trusted Industrial Commutator Corp

As a dedicated industrial commutator corp, XDC invests heavily in testing and inspection to ensure each unit performs reliably from day one. Our quality system is based on ISO 9001 principles, and we support CE-compliant documentation where required.

Spin and Overspeed Tests

• Spin testing at elevated speed (often above rated rpm) and temperature to verify mechanical integrity

• Overspeed margins designed to meet or exceed OEM specifications, giving you wide safety margins in service

Electrical and Insulation Tests

• High-voltage dielectric testing between adjacent segments and between segments and ground

• Routine verification of creepage and clearance distances

• Resistance and continuity checks to confirm correct connections and uniform current distribution

Dimensional and Surface Checks

• Detailed dimensional checks for OD, ID, length and segment pitch

• Surface finish and runout inspections on the brush track

• Verification of the brush seating area to help achieve low-sparking operation from commissioning

Materials and Engineering

XDC engineers each industrial commutator from high-quality raw materials selected for mechanical strength, electrical performance and thermal stability.

Copper Segments and Insulation

- Electrolytic copper or silver-bearing copper segments for high conductivity and low losses

- Mica and resin-based insulation systems to withstand high voltages and limit partial discharges

- Heat-resistant insulation up to Class F or Class H depending on your specification

Mechanical Strength and Balancing

- Robust hubs in cast steel or SG iron for high mechanical strength

- Precision machining to ensure tight runout and concentricity tolerances

- Dynamic balancing of each commutator to reduce vibration and extend bearing life

XDC Industrial Commutator Specifications and Options

As a specialized industrial commutator corporation, XDC offers a broad, configurable range of sizes and designs so you can match our product directly to your DC motor commutator requirements.

Size and Geometry

- Outer diameter (OD): approx. 120 mm to 3000 mm

- Inner diameter / shaft hole (ID): machined to your shaft and keyway dimensions

- Brush track length: optimized to your brush size and current density

- Overall length: matched to your armature, hub and bearing arrangement

- Segment count: typically 24–700 segments, including standard counts such as 24, 48 and 57 segments for traction motor commutator designs

Construction Types

We manufacture multiple industrial commutator constructions to match OEM designs and retrofit needs:

- Molded commutators for high-performance DC motors

- Groove and dovetail segment designs for heavy industrial drives

- V-ring / shell-type commutators for large traction and mill motors

Why Choose XDC as Your Industrial Commutator Company?

Choosing the right industrial commutator company is about more than price. It is about reliability, technical support and long-term partnership.

Focused Expertise

XDC is not a general motor parts supplier. We are a commutator specialist. That focus means:

• Deep knowledge of DC motor and traction motor commutator design

• Practical experience with common failure modes such as bar lifting, sparking and uneven brush wear

• The ability to optimize segment geometry, materials and insulation to match your real operating conditions

Broad Capability

As a global-facing industrial commutator company, we support:

• Single emergency replacements and short runs for repair shops

• Medium batches for regional OEMs and system integrators

• Long-term series production with strict change-control for major motor manufacturers

Reliable Performance and Lifecycle Cost

Our goal is not just to sell a component. We help you reduce life-cycle cost by:

• Extending commutator and carbon brush life

• Minimizing unplanned outages

• Lowering maintenance effort through stable commutation and high build quality

Applications of XDC Industrial Commutators in Heavy Industry

Wherever you see a heavy-duty brushed DC motor, an XDC industrial commutator can be designed to fit.

Steel and rolling mills

Main mill stands, coilers, shears and auxiliary drives working under severe shock loads and variable speed.

Cranes, hoists and winches

Series-wound DC motors requiring high starting torque, frequent reversing and dynamic braking.

Mining and tunnelling

Mine hoists, conveyors and ventilation fans in dusty, damp and abrasive conditions.

Rail traction and electric vehicles

Traction motor commutators for locomotives and industrial electric vehicles.

Power generation and petro-chemical plants

DC drives on pumps, fans and process lines where unplanned downtime is costly.

Marine propulsion and auxiliaries

DC propulsion motors and deck machinery exposed to vibration and corrosive atmospheres.

Contact Us – Talk to XDC, Your Industrial Commutator Corporation Partner

If you are looking for a long-term industrial commutator corporation partner in China, XDC is ready to support your next project.

When You Contact Us, Please Share:

- Motor make and model

- Key dimensions (OD, ID, length, number of segments)

- Drawings or clear photos

Our engineers will quickly confirm feasibility, propose a design and provide a clear quotation and delivery time.

You can reach XDC through email, phone or your preferred messaging platform. Whether you need a single emergency replacement or a full range of industrial commutator sizes for OEM production, our team is here to help.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Industrial Commutator Selection and Use

A: Start from the motor nameplate and existing commutator. We need OD, ID, length, number of segments, operating voltage, speed and power. With this information and your application details, XDC can propose a matching or upgraded design.

A: Yes. Send us your drawing or a used commutator, along with photos and basic motor data. We reverse-engineer the design, define materials and tolerances, and supply a sample for validation before series production.

A: Our products operate in steel and rolling mills, cement and power plants, mines, paper and textile lines, marine applications, cranes and lifting systems, rail traction and many other heavy-duty environments.

A: Lifetime depends on load, speed, brush grade, maintenance and environment. With correct brush selection, proper seating, regular inspection and clean operating conditions, XDC commutators can run reliably for many years before resurfacing or replacement is required.

A: XDC focuses on commutators and related solutions for brushed DC motors and traction motors. If you also need industrial slip rings, our team can review your requirements and propose an appropriate solution or introduce trusted partners.

A: We provide installation guidelines covering shaft fits, keyways, tightening procedures, brush seating and recommended checks before start-up. For critical projects, remote support is available to help your team achieve low-sparking operation quickly.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…