Function of Split Ring Commutator in an Electric Motor

If you’ve ever stared at a simple DC motor diagram and thought, “Okay, but what does that weird broken copper ring actually do?” — this is for you.

The split ring commutator is tiny, but it quietly decides whether your motor:

- keeps spinning smoothly in one direction, or

- just twitches back and forth awkwardly and gives up.

By the end of this article you’ll not only know the textbook answer, you’ll also have a mental animation of what’s happening every half-turn inside the motor.

- In this guide, you’ll learn:

- What a split ring commutator physically is

- How it keeps torque in the same direction despite current reversals

- Why a DC motor won’t work properly without it

- How it differs from slip rings in AC machines

Table of Contents

1. Quick refresher: how a simple DC motor works

Before we zoom in on the split ring, let’s set the stage.

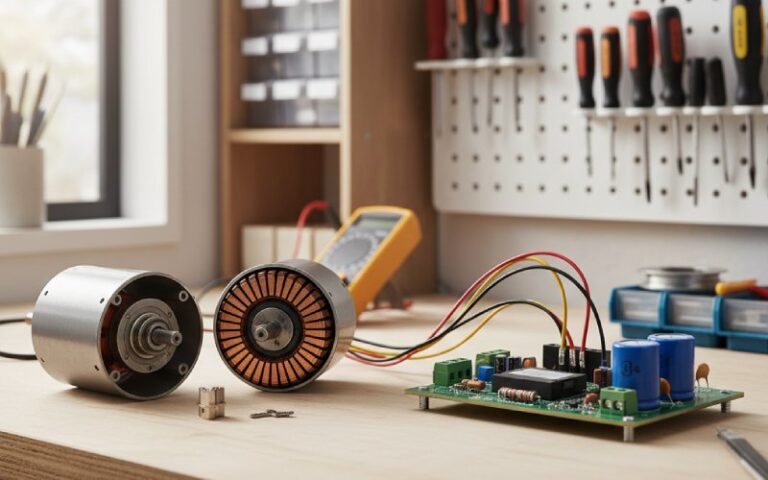

A basic DC motor has:

- A coil (armature) of wire that can rotate

- A magnetic field, usually from permanent magnets

- A DC power source (battery or DC supply)

- Brushes and a commutator to get current into the spinning coil

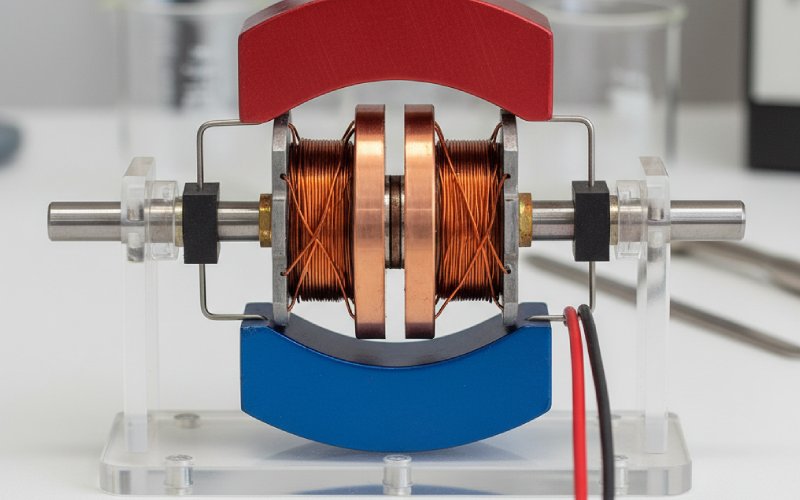

When current flows through the coil in a magnetic field, each side of the coil feels a force in opposite directions (thanks to the motor effect / Fleming’s left-hand rule). One side is pushed up, the other down, so the coil turns.

The catch: without some clever trick, after half a turn the forces flip direction and the coil would just rock back and forth instead of spinning continuously.

That “clever trick” is the split ring commutator.

- A simple DC motor typically includes:

- Coil (armature) on a rotating shaft

- Permanent magnet (or field electromagnet)

- DC supply (battery or DC source)

- Split ring commutator

- Carbon brushes pressing on the commutator

2. What exactly is a split ring commutator?

Physically, a split ring commutator is:

- A copper ring cut into two halves, mounted on the motor shaft

- Each half is connected to one end of the coil

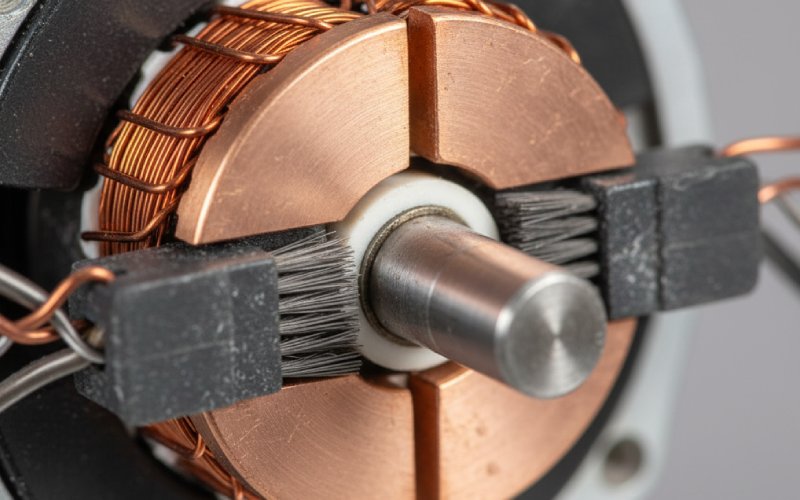

- Two carbon brushes rest on these halves, connected to the external DC supply

As the shaft (and coil) rotate, the brushes stay still but always touch one or the other half of the ring.

Think of it as a rotary switch or a mechanical “polarity flipper” that’s synchronized with the coil’s rotation.

- Key physical features of a split ring commutator:

- Made of copper segments (two segments in the simplest motor)

- Segments are insulated from each other

- Fixed to the rotor shaft

- Each segment connects to an armature coil end

- Brushes press on the outer surface to feed current

3. The core function: reversing current every half turn

Here’s the heart of it:

The function of the split ring commutator in a DC motor is to reverse the direction of current in the coil every half revolution, so that the torque on the coil always acts in the same rotational direction, allowing continuous rotation.

Let’s walk through one full turn in slow motion.

- Start position (0°):

- Side AB of the coil carries current “forward”, side CD carries current “back”.

- In the magnetic field, AB is pushed down, CD is pushed up → coil starts to rotate.

- Approaching 90°:

- The coil moves toward vertical.

- Torque is momentarily small when the coil is exactly vertical, but inertia keeps it going.

- At 90° (half turn):

- The coil is vertical.

- The brushes now cross the gaps between commutator segments and start touching the opposite halves.

- This neatly reverses the current direction in the coil.

- From 90° to 180°:

- Current in AB and CD has reversed, but so has the coil’s orientation.

- Result: the forces on each side still push in the same overall rotational sense. The torque direction is preserved.

So although current is flipping, the commutator makes sure the torque doesn’t. That’s why the motor spins rather than shuddering.

- In simple exam-style wording, the split ring:

- Reverses current in the armature coil every half turn

- Keeps the torque on the coil in the same direction

- Ensures continuous rotation in one direction

- Maintains a DC output / input at the external terminals (for generators / motors respectively)

4. With vs. without the split ring (and vs. slip rings)

It’s easier to see its purpose by comparing different scenarios.

Comparison table

| Scenario | What happens to current in the coil? | What happens to torque? | Typical use |

| DC motor with split ring commutator | Reversed in the coil every half turn | Kept in the same rotational direction → smooth spin | Simple DC motors |

| DC motor with slip rings instead | Direction in the coil stays the same w.r.t. supply | Torque reverses every half turn → coil just rocks | Not used – fails as DC motor |

| AC machine with slip rings | Alternating current passes freely between rotor & stator | Torque designed to work with naturally alternating fields | AC generators & some motors |

| Brushless DC motor (electronic comm.) | Current switched electronically in stator windings | Torque direction controlled by electronics instead of ring | Modern BLDC drives |

In short:

- Split ring → “I will reverse the coil current for you at the perfect moments so your torque stays one-way.”

- Slip ring → “I’ll just transfer whatever current you give me; I’m not here to flip polarity.”

- The split ring commutator’s role, summarized:

- Acts as a mechanical inverter for the armature current

- Synchronizes current reversal with rotor angle (every half turn)

- Converts the natural “back-and-forth” effect into steady rotation

- Makes a DC motor behave the way we expect: smooth and directional

5. Deep dive: what problem is the split ring solving?

Let’s imagine we remove the split ring commutator and somehow connect the coil directly to the DC supply through slip rings.

At the start, forces on the sides of the coil cause it to rotate. But after it swings through half a turn:

- The side that was previously under the north pole is now under the south pole.

- The current direction in each side has not been flipped (because there’s no commutator).

- Magnetic forces now act in the opposite direction → torque reverses.

The motor would act like a person trying to push a door first forward, then backward, then forward, always stopping in the middle. That’s why the coil would simply oscillate or stall around the vertical position instead of spinning.

The split ring commutator steps in and says:

“Every time the coil reaches that awkward halfway point, I’ll swap its connections so that the forces don’t change their overall direction.”

That’s the magic. No advanced math needed — just well-timed polarity flipping.

- Conceptual picture to remember:

- Without commutator → torque direction flips each half turn → rocking motion

- With split ring commutator → current flips instead → torque stays one-way → full rotation

- In generators, the same mechanism acts as a mechanical rectifier to give DC from an AC-like induced voltage

6. Structure + brushing: how it actually makes contact

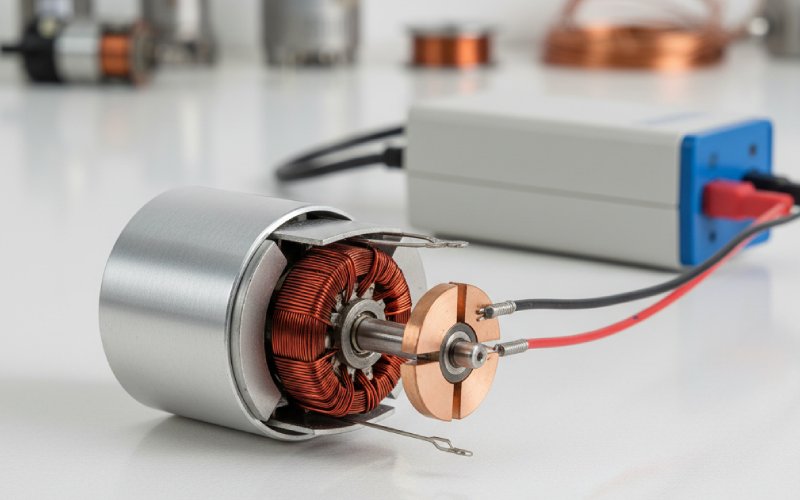

In real motors, the commutator isn’t just two ugly bits of copper. It’s engineered:

- Multiple copper segments are fixed around the shaft.

- Segments are insulated from each other using materials like mica or plastics.

- Spring-loaded carbon brushes press on the outer surface and slide over segments as the shaft rotates.

- Each segment is wired to a particular armature coil.

In a very simple school-level DC motor:

- The “commutator” is just two copper half-rings (the split ring)

- Each half-ring connects to one end of a single coil

- Two brushes feed DC into these halves, allowing the coil to spin while staying electrically connected

That’s all it needs to be: a rotating interface that periodically swaps which coil end is connected to which supply terminal.

- Why use brushes and a commutator at all?

- You can’t twist wires endlessly as the rotor spins.

- You need a sliding contact between the fixed world and the rotating world.

- The commutator & brushes form that interface and handle the current reversal job.

7. Split ring vs slip ring — how to explain the difference clearly

This is a classic exam/interview trap, so let’s make it crystal-clear.

- A split ring is:

- A copper ring cut into segments (usually two in simple DC motors).

- Used as a commutator: it reverses current direction in the rotor windings every half turn.

- Common in DC motors and generators.

- A slip ring is:

- A continuous ring (not split) used just to transfer power/signals to a rotating part.

- It does not reverse current by itself.

- Common in AC generators, slip-ring induction motors, and rotating systems like wind turbines.

In one line:

Split ring = commutator, reverses current. Slip ring = connector, passes current.

- Easy memory hooks:

- “Split ring” → split the connections, flip the current

- “Slip ring” → let current slip through continuously

- Split → DC motors; Slip → AC machines (mostly)

8. Real-world engineering notes: limits of mechanical commutation

Mechanical commutators, including split ring types, are brilliant but not perfect:

- They suffer from friction and wear where brushes rub on copper segments.

- There can be sparking and electrical noise, especially at high speed or high current.

- They need periodic maintenance and brush replacement.

That’s one of the reasons many modern drives now use brushless DC motors (BLDC) or AC induction motors:

- BLDC motors remove the mechanical commutator entirely and replace it with electronic switching of currents in the stator.

But in education, basic lab motors, toys, and simple DC drives, the split ring commutator is still the clearest, most tangible way to see how we can turn electricity into a one-way spinning motion.

- To remember the big picture:

- Commutator = “current manager” of the rotor

- Split ring = simplest physical form of that commutator in a DC motor

- Its job is not just to connect, but to connect in the right direction at the right time

9. Quick recap

The function of the split ring commutator in an electric (DC) motor is to:

- Reverse the direction of current in the armature coil every half turn

- Keep the torque on the coil acting in one consistent rotational direction

- Ensure the motor doesn’t just rock back and forth, but spins continuously

- Provide the sliding electrical connection between the stationary supply and the rotating armature

If you can visualize that little copper ring flipping the coil’s polarity like a perfectly timed light switch, you understand more than most textbook paragraphs ever convey.