Fuel Pump Commutator Supplier & Manufacturer China

As China’s premier commutator manufacturer, XDC designs and manufactures the fuel pump commutator for demanding automotive and motorcycle applications. Every product is engineered around real test data, precise manufacturing tolerances, and fuel-specific materials to ensure reliable performance in gasoline, diesel, ethanol blends, and even challenging biodiesel environments.

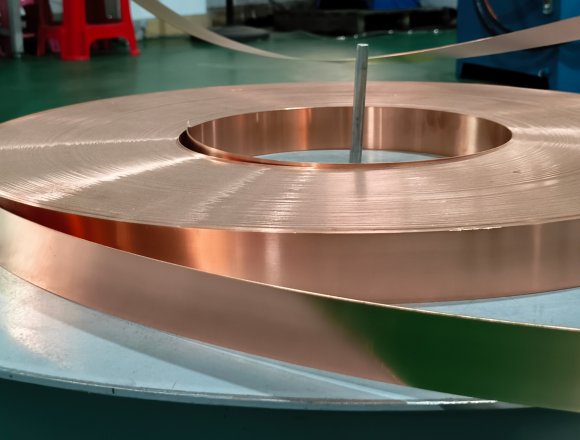

Advanced Materials: Copper, Graphite, and Carbon

- Copper commutator options deliver excellent conductivity and are ideal for clean gasoline or diesel systems.

- Carbon and graphite commutator options are selected for aggressive fuels, helping prevent corrosion and limiting arc erosion in the contact area. Insulating mica or molding compound between segments is specified to handle required voltage and thermal loads.

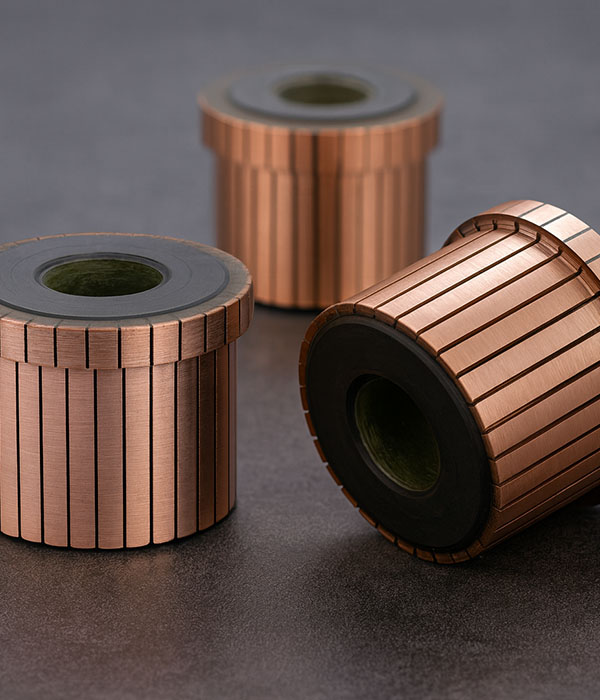

Fuel Pump Commutator Solutions by XDC

Our Fuel Pump Commutators are engineered for precise current switching in automotive fuel pump motors. From micro sizes for compact assemblies to multi-segment designs for higher loads, we offer molded and hook-type commutators with optimized copper alloys, insulation and balance. Stable commutation, low brush wear and long service life support reliable fuel delivery across passenger vehicles, commercial vehicles and customized fuel pump applications.

7.6mm 3-Segment Motor Commutator

Compact copper commutator with 7.6 mm outer diameter and 3 precisely machined segments, designed for miniature DC motors needing stable current switching and reduced electrical noise.

7mm 5-Segment Micro Commutator

Compact copper commutator with 7 mm outer diameter and 5 segments, ensuring reliable current reversal, smooth brush contact, and long service life in miniature DC motors.

25.5mm 31-Segment Fuel Pump Commutator

Precision-engineered hook type commutator featuring a 25.5mm OD and 31 copper segments. Designed specifically for automotive fuel pump motors, ensuring superior conductivity, wear resistance, and extended service life at high rotational speeds.

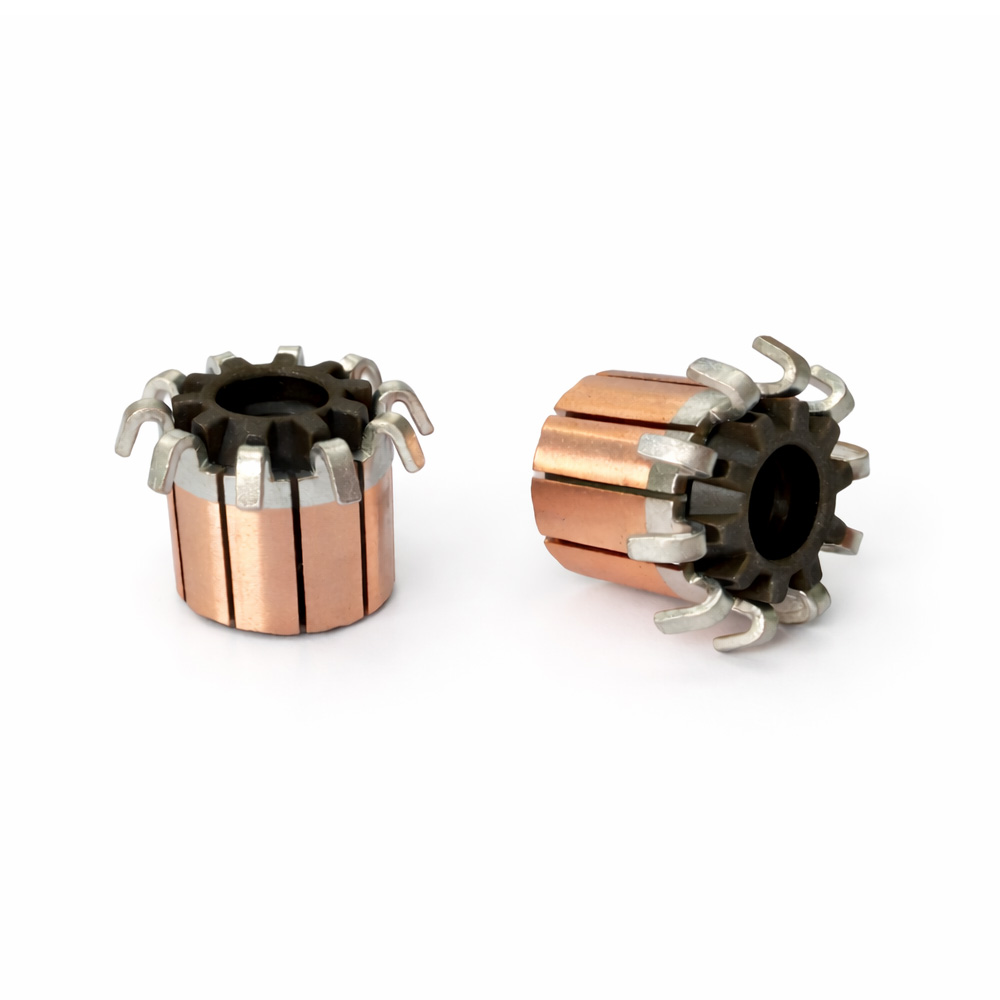

15.2mm 10-Segment Motor Commutator

Robust copper commutator with 15.2 mm outer diameter and 10 segments, providing stable current reversal and low sparking for medium-power DC motors and power tools.

11.4mm 14-Segment Motor Commutator

11.4 mm outer diameter copper commutator with 14 segments, ensuring smooth current commutation and low brush wear for compact high-speed DC motors.

5.6mm 5-Segment Micro Commutator

Copper commutator with 5.6 mm outer diameter and 5 segments, providing precise current switching, low contact resistance and reliable performance for compact DC motors and micro drive applications.

15mm 10-Segment Axial Commutator

15 mm outer diameter commutator with 10 copper segments and molded insulation, delivering consistent current switching and durability for medium-power DC motors and automotive applications.

17-Segment Slot Type Motor Commutator

Robust 17-segment slot type commutator designed for DC motors. Features precision-machined risers for secure wire welding. Made from high-grade copper to ensure optimal conductivity and thermal stability under load.

Fuel Pump Commutator Design and Construction

Our fuel pump commutator is built for compact, submerged electric fuel pump motors, typically brushed DC motors with carbon brushes and a high-speed armature.

Flat / planar commutator architecture

We specialize in flat and planar commutator designs for in-tank electric fuel pump motors. Segmented copper or carbon bars are arranged with tight control of outer diameter, inner diameter, copper height, and total commutator height to match your armature and housing.

Precisely formed commutator segments

Each commutator segment is manufactured with controlled contact surface finish to minimize commutator arcing, reduce brush wear, and stabilize commutator resistance. Segment count, bar geometry, and slot configuration are optimized for smooth commutation at high rotational speeds.

Stable brush interface

Our designs pair accurately machined commutator surfaces with compatible carbon brushes and brush springs. The combination of surface finish and spring force helps control brush vibration, noise, and carbon dust generation inside the fuel tank module.

Custom engineering for your DC motor

XDC supports complete matching to your fuel pump motor armature: shaft diameter, keyway, balance requirements, and rotor/stator geometry. We provide drawings, 3D models, and sample builds to verify assembly and performance.

Carbon and Copper Options for Your Fuel Pump Commutator

XDC supplies a full range of copper, graphite, and carbon commutator solutions tailored to different fuel pump motor requirements:

- Copper flat and hook-type designs for standard gasoline and diesel in passenger cars, light commercial vehicles, and small machinery.

- Carbon and graphite planar designs for vehicles operating on ethanol blends, E50, E85, or biofuel-rich regions, where corrosion resistance and arc erosion control are critical.

- Options for different voltage systems (12 V, 24 V, 48 V, and higher), current levels, and pump flow demands.

All variants are backed by process control for runout, concentricity, copper height, segment insulation thickness, and dynamic balance.

Why Choose Us – XDC Fuel Pump Commutator Manufacturer in China

As XDC, China’s premier commutator manufacturer, we offer a combination of technical depth and manufacturing scale:

Specialization in automotive fuel pump commutator products

Dedicated lines for electric fuel pump motors, including in-tank submerged applications for gasoline, diesel, and ethanol fuels.

Integrated tooling and process control

In-house tooling design for commutator segments, molds, and fixtures ensures consistent geometry from prototype to mass production.

Strict quality management

Each batch undergoes dimensional inspection, electrical testing, and appearance checks. We monitor commutator resistance, insulation integrity, surface finish, and visual defects to meet OEM and aftermarket standards.

Custom solutions and fast sampling

We support custom drawings, reverse engineering from samples, and rapid prototype builds to help you launch or upgrade your fuel pump motor platform quickly.

Applications

XDC commutators are used in a wide range of fuel pump motor applications, including:

In-tank electric fuel pumps for passenger cars and SUVs

Motorcycle and powersports fuel pump modules

Light commercial vehicle and small diesel system pumps

High-flow and performance-oriented pump

Contact Us

Ready to optimize your electric fuel pump motor design?

- Please send us your product drawings.

- Please inform us of the quantity, material,

- Special requirements for packaging, marking, or testing.

Get in touch with XDC via your preferred channel (email or contact form) and our technical sales team will respond with tailored support.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – XDC Commutator Products

The commutator switches current between the armature windings of a brushed DC motor, working together with carbon brushes and brush springs. In a submerged fuel pump, it must deliver smooth commutation while operating continuously in fuel, under high speed and inductive load.

Yes. We can design to your shaft size, armature diameter, segment count, current level, speed, and fuel type. You can send us a drawing or a physical sample, and we will develop a matching commutator design with the required tolerances and test plan.

We offer copper, graphite, and carbon commutator solutions, combined with carefully selected insulating materials such as mica or molding compounds. The choice depends on your fuel (gasoline, ethanol, diesel, biodiesel), current levels, and cost targets.

We run bench tests at representative speeds and currents in specific fuels, monitoring arc duration, brush wear, and commutator surface condition. Results from gasoline, ethanol, and E50-type blends are used to validate material combinations and adjust geometry before mass production.

Please share: motor drawings or samples, operating voltage and current, target speed, fuel specification, expected lifetime, and estimated annual volume. With this information, we can propose a suitable commutator design, confirm feasibility, and prepare pricing and lead time details.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…