Flat Commutator

A flat commutator (also called a disc or planar commutator) is a low-profile commutator structure where copper or carbon segments are arranged in a flat disc instead of a cylindrical ring. It provides the current switching interface between the armature winding and the carbon brush system in brushed DC motors.

Our engineering team can work from your drawings, samples or performance requirements to match the commutator design to your rotor stack, brush system and manufacturing process.

Flat Commutator Manufacturer in China

XDC is a leading custom commutator manufacturer in China, specializing in flat commutator design and production for automotive, appliance and power tool DC motors. We combine precise copper segment machining, robust insulation systems and strict quality control to deliver reliable commutator solutions that integrate smoothly into your armature and production line.

Flat Commutator Manufactured by XDC

Examine XDC’s collection of flat commutators, engineered for compact and planar motor designs. We specialize in custom-manufacturing components that follow your technical schematics precisely. Our workflow initiates with pilot units for your approval before proceeding to full-batch fulfillment. Observe our precision-crafted parts below, and directly send us your drawings to get a quote.

49mm Flat Commutator

Engineered for space-saving “pancake” motors, this 16-segment face-type unit significantly reduces axial length. Its planar contact surface ensures reliable conduction in compact, low-profile automotive or industrial designs.

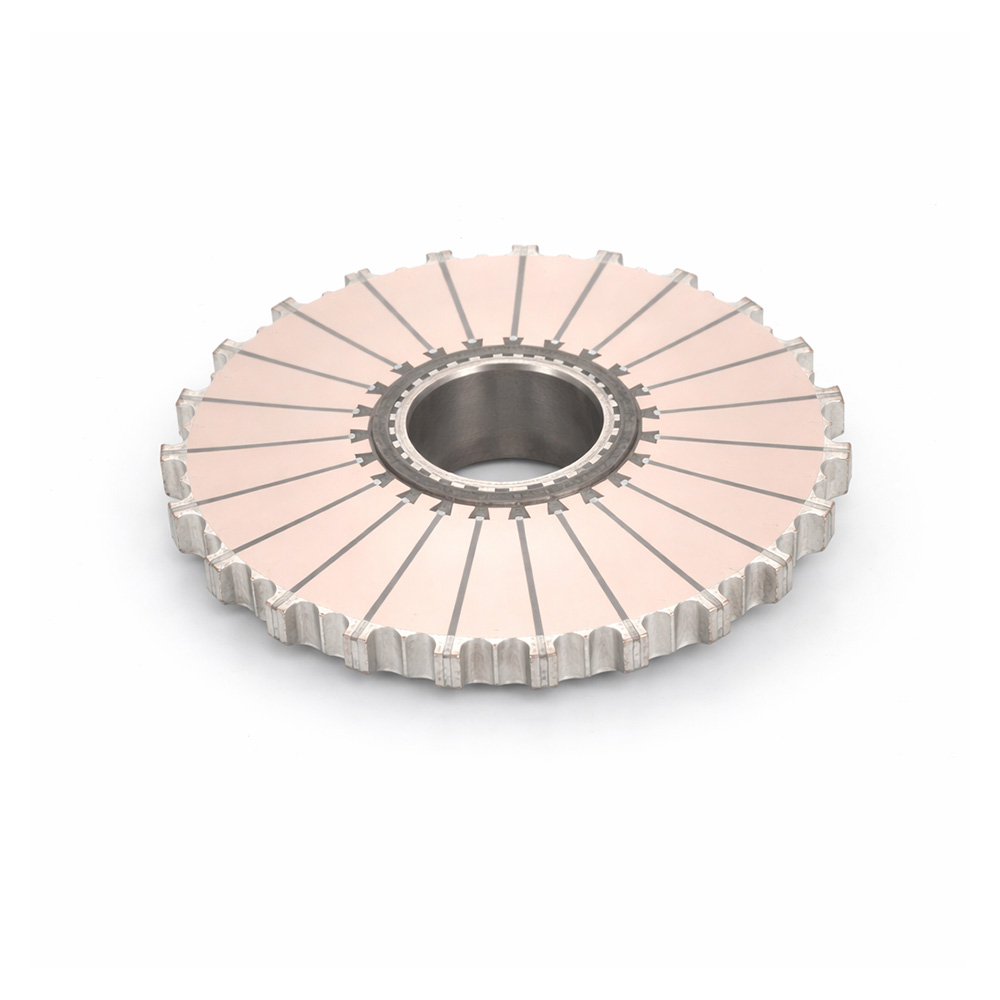

57mm Face-Type Commutator

Featuring a precision-ground planar surface, this 57mm unit optimizes axial brush contact. Its stable disk geometry minimizes vibration and wear in high-performance thin-profile motor applications.

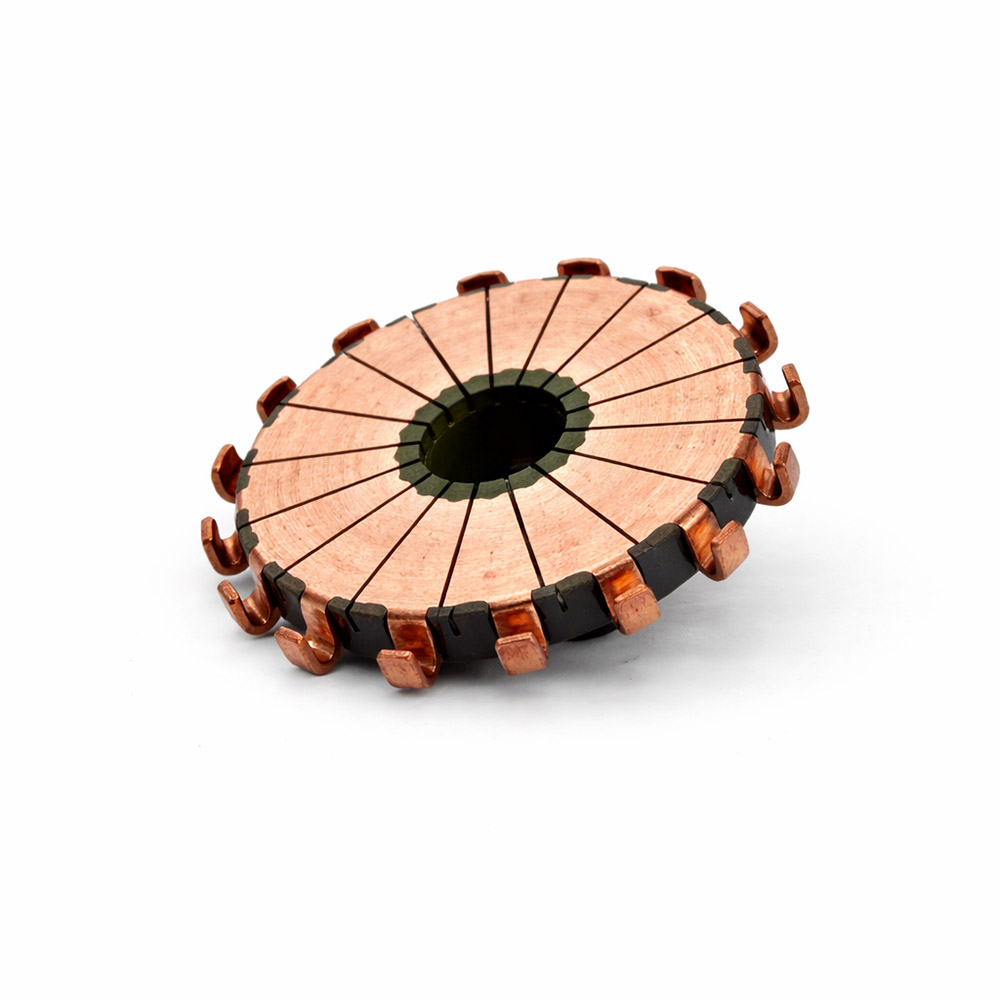

44mm 23-Bar Flat Commutator

Utilizing a high-resolution 23-segment layout, this planar unit effectively minimizes magnetic cogging. Its thin axial profile and precise segment geometry ensure smooth current rectification for compact drives.

47.6mm 16-Bar Face Commutator

Featuring a robust 16-segment planar architecture, this 47.6mm unit ensures stable axial contact. Its precision-molded segments are engineered to prevent thermal deformation and maintain surface flatness in high-speed, space-critical motor applications.

Dimensional Range

XDC supports a wide dimensional envelope:

- Outer diameter (OD): approx. 2.5–150 mm

- Inner diameter (ID): matched to your shaft and hub design

- Height / thickness: tuned according to armature length and brush track requirements

- Segments / bars: from 3 bars in small micromotors to 96+ bars in larger motors

Materials and Insulation

To achieve stable commutation and long service life, XDC carefully selects materials for each flat commutator design:

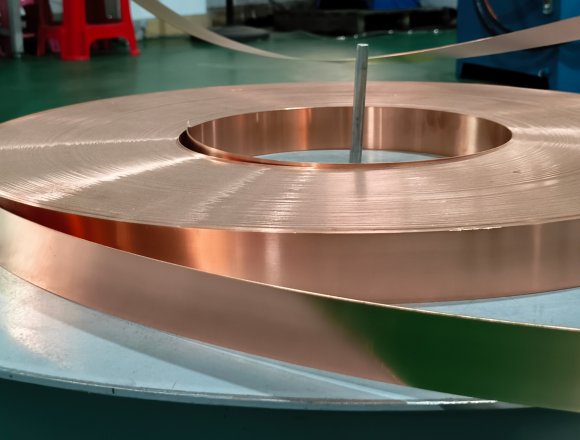

- Copper segments

- Electrolytic copper or TUY-grade copper

- Optional silver-bearing copper with about 0.03–0.08% Ag for improved conductivity and temperature capability

- Carbon / composite segments (for planar carbon commutator options)

- Carbon pads anchored through the insulating body

- Suitable for high-speed and wear-sensitive designs

- Insulating hub and body

- Moulded bakelite powder or high-performance synthetic resin

- Designed to resist mechanical stress and thermal load during press fitting and operation

- Inter-segment insulation

- Mica or micanite sheets between copper bars

- Proven structure for high insulation resistance and stable bar-to-bar separation

Process Highlights

XDC combines proven manufacturing methods with strict inspection to ensure repeatable flat commutator quality.

- Segment production

- Precision stamping or machining of copper segments

- Controlled burr levels and segment geometry for uniform contact area

- Moulding and assembly

- Segments arranged in a disc cavity and moulded with bakelite or synthetic resin

- Option for carbon pads fixed on metal laminates with through-hole pins for strong anchoring

- Turning, grinding and undercutting

- Commutator face turned and ground to achieve the required flatness and surface roughness

- Insulation grooves between segments undercut using dedicated flat commutator undercutting equipment

- Finishing and protection

- Cleaning of slots and surfaces

- Corrosion-resistant packaging suitable for automated assembly lines

Quality and Inspection

Our quality system focuses on traceable and measurable parameters:

- Dimensional inspection of OD, ID, height and segment pitch

- Flatness and bar-to-bar deviation checks to keep the brush track stable

- Dielectric strength and insulation resistance testing according to your specification

- Spin tests and visual inspection of resin hubs for cracks, voids or deformations

XDC operates under a strict quality management framework and can align with automotive and export-oriented requirements for documentation, lot traceability and PPAP-style approvals where needed.

Why Choose XDC as Your Flat Commutator Partner

Choosing the right flat commutator supplier has a direct impact on motor performance, brush life and production efficiency. XDC offers a combination of engineering capability and manufacturing scale tailored to OEM and ODM customers.

1. Deep Customisation Capability

• Support for special OD, ID and height combinations

• Custom segment counts and bar shapes for your armature design

• Hook type, riser type or fully planar connection styles

• Material selection (standard copper, silver-copper, carbon overlays) based on your electrical and thermal targets

2. Strong Tooling and Existing Platform

• Hundreds of existing moulds and designs across 2.5–150 mm OD range

• Ability to adapt an existing platform to shorten development time

• Optimised commutator geometries for fuel pump motors, starter motors, appliance motors and power tool motors

3. Stable Quality and Consistent Supply

• Robust process control from copper bar to finished flat commutator

• In-line and final electrical and dimensional checks

• Packaging and logistics solutions aligned with high-volume export needs

4. Cost-Effective Production in China

• Competitive cost structure combined with engineering support

• Experience serving customers worldwide with customised commutators and armature components

Flat Commutator Applications & Usage Scenarios

XDC designs each flat commutator around real motor applications. Common usage scenarios include:

Automotive DC Motors

• In-tank automotive fuel pump motors

• Starter motors and related auxiliary motors

• Window lift motors and windshield wiper motors

• Blower and fan motors in HVAC systems

• In-tank automotive fuel pump motors

• Starter motors and related auxiliary motors

• Window lift motors and windshield wiper motors

• Blower and fan motors in HVAC systems

Household Appliance Motors

• Vacuum cleaners and small suction units

• Washing machine motors and small pumps

• Kitchen appliances such as mixers, juicers and food processors

• Vacuum cleaners and small suction units

• Washing machine motors and small pumps

• Kitchen appliances such as mixers, juicers and food processors

Power Tool and Industrial Motors

• Power tools such as drills, saws, grinders and hammers

• Light industrial DC motors used in machinery, fitness equipment and doors

• Power tools such as drills, saws, grinders and hammers

• Light industrial DC motors used in machinery, fitness equipment and doors

Micromotors and Precision Drives

• Small gearmotors and actuators

• Compact fans and blowers

• Vending and office equipment DC drives

• Small gearmotors and actuators

• Compact fans and blowers

• Vending and office equipment DC drives

Contact Us for Flat Commutator Solutions

If you are developing a new motor or optimising an existing design and need a reliable flat commutator partner in China, XDC is ready to support you.

Please share:

- Drawings or photos of your current commutator and armature

- Required dimensions (OD, ID, height, segment count)

- Voltage range and basic electrical requirements

- Estimated annual volume

Our engineering and sales teams will review your request and provide a tailored flat commutator proposal, including design suggestions, sample lead time and production plan.

Contact XDC today to discuss your next flat commutator project and secure a stable, high-quality supply for your DC motor production.

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

Flat Commutator FAQ

Below are some of the questions we frequently receive from customers considering a flat commutator solution.

A flat commutator arranges its segments in a disc shape, while a cylindrical commutator uses a drum-like ring. The disc configuration reduces axial length and is often preferred in compact DC motors where space is limited. Cylindrical versions are more common in larger, traditional armature layouts.

To design a custom flat commutator, XDC typically needs:

- Required OD, ID and height

- Number of segments and brush dimensions

- Target voltage range and basic electrical requirements

- Any specific material, insulation class or testing standards

Drawings or physical samples help us accelerate design confirmation.

Yes. XDC regularly develops flat commutator designs for automotive fuel pump motors and starter-related applications. We can use copper or silver-copper segments, appropriate insulation materials and testing levels to match typical 12–60 V DC systems used in automotive environments.

We support planar commutator and disc-type configurations for micromotors, such as the example with 16 mm OD, 2.3 mm ID, 6.1 mm height and 6 bars. These are suitable for compact DC drives in automotive and device applications where low profile and fine tolerances are essential.

XDC uses controlled copper grades, monitored incoming inspection and precision stamping/machining for segments. For insulation, we select suitable resin systems and mica/micanite combinations, then verify dielectric strength and insulation resistance on each batch of flat commutator products. Dimensional and visual inspections ensure that the hub and segments remain structurally sound.

Our standard flat commutator and disc commutator range covers approximately 2.5–150 mm outer diameter. Within this range we have a large number of existing designs, and we can create new tooling if your project requires a unique size or structure.

Yes. XDC can supply prototype or pilot samples of your flat commutator for validation. Once you approve dimensions, material selection and test results, we move to mass production under agreed quality and delivery terms.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…