Electric Motor Commutator Repair: From Scary Sparks to Smooth Running

If you’ve ever watched an electric motor start to spit sparks, lose torque, or sound “rough” at speed, there’s a good chance the commutator is trying to get your attention. For DC and universal motors, a healthy commutator is the difference between years of quiet, productive work and a sudden, expensive failure.

This guide pulls together what top repair shops, motor OEMs, and maintenance associations recommend, then goes a level deeper: not just what to do, but why you’re doing it. The goal is to help you understand commutator repair well enough to have intelligent DIY attempts on small motors – and even more importantly, to know when a job truly belongs in a professional shop.

- In this guide, you’ll learn:

- What the commutator actually does in the motor (in human terms)

- How to spot early warning signs of commutator damage

- A structured, four-phase approach to commutator repair

- The difference between “clean & dress” vs “turn & undercut” repairs

- How to test the motor after repair and avoid flashovers and repeat failures

Table of Contents

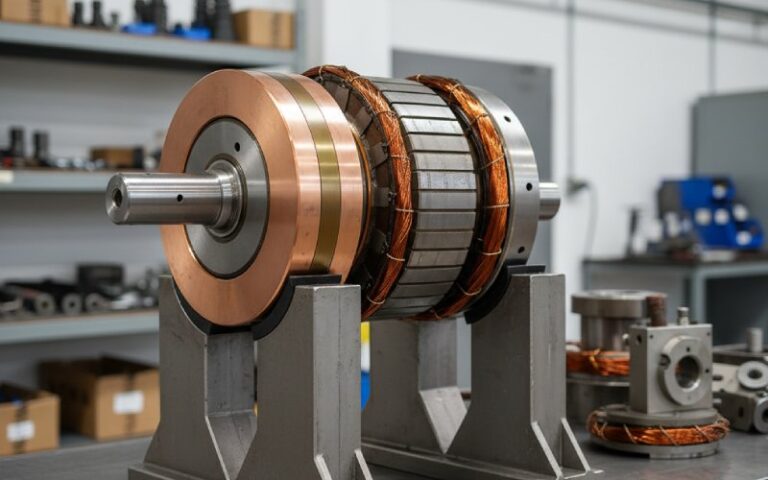

1. What Your Commutator Actually Does

Inside a DC or universal motor, the commutator is essentially a rotating mechanical switch made of segmented copper bars. Brushes press against these bars, feeding current into different armature windings as the rotor turns. That timed switching is what keeps the motor producing torque in a consistent direction.

Every time a bar passes under a brush, you get:

- Electrical contact (current flows into that coil)

- A brief interruption (as the brush leaves one bar and lands on the next)

- A small arc during the break/make interval

Over time, heat, dust, vibration, and current all conspire to roughen the surface, loosen segments, or contaminate the contact area. That’s why commutator repair is never just “cosmetic polishing” – it’s restoring a precisely-timed switching surface so the electrical and mechanical worlds cooperate again.

- At a glance: what can go wrong with a commutator

- Dirty or contaminated surface – carbon dust, oil, metallic particles causing tracking and uneven contact

- Rough, grooved, or out-of-round bars – leads to brush bounce, noise, and heavy sparking

- High mica – insulation standing proud of the copper so brushes ride on mica, not metal

- Loose or lifted bars – mechanical instability, localized heating, often a precursor to serious failure

- Wrong brush grade or spring tension – excessive wear, chatter, or poor commutation even with an otherwise good commutator

2. Safety First & When NOT to DIY

Before you grab sandpaper and a screwdriver, pause. Commutator repair happens inches from energized conductors and stored energy. Mistakes can mean shock, arc flash, or destroying an expensive motor. Many professional sources stress that major electric motor repairs are best performed by qualified personnel, and that opening a motor often voids OEM warranties.

For small tools and low-voltage hobby motors, careful DIY work can make sense. For larger industrial or critical applications, your biggest “repair win” is often early detection and sending the machine to a certified shop before the commutator is beyond economical recovery.

- Absolutely hand the job to a professional if:

- The motor is large, high-power, or critical to production

- Nameplate voltage is above low-voltage tool levels and you’re not qualified in electrical safety

- You suspect loose, lifted, or cracked bars, or the commutator has burned sections

- There has been a flashover (an arc across bars or to brush holders/ground)

- You don’t have access to safe test equipment (insulation tester, bar-to-bar tester)

- The motor is still under warranty and the OEM requires authorized repair centers

3. Preparing for Commutator Repair

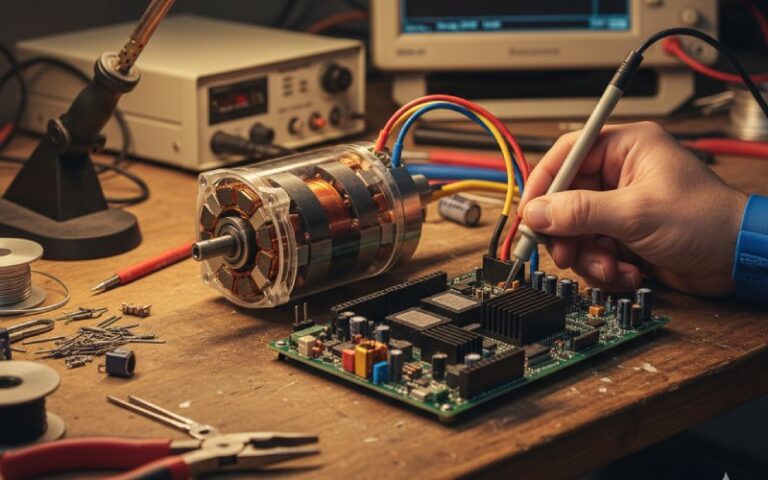

Assuming your motor is a candidate for in-house work (e.g., small DC motor, power tool, low-voltage equipment), preparation is where you win or lose most of the battle.

First, make the job safe: isolate and lock out all power, discharge any capacitors, and confirm zero energy before opening anything. Then set up a clean, well-lit area. Many guides point out that contamination control is a huge part of successful commutator work – both for the motor and for your lungs. Carbon dust should be captured, not blown around the shop.

Finally, gather whatever OEM data you can (drawings, dimensions, brush grade) and decide upfront whether you’re doing light maintenance (cleaning, minor dressing, brush replacement) or if the condition will demand machining and undercutting in a proper shop.

- Basic tools & materials you’ll typically want on hand

- Insulated hand tools and proper PPE (gloves, safety glasses, dust mask/respirator)

- Non-metallic scrapers, lint-free cloths, and approved electrical cleaning solvent

- Very fine non-conductive abrasive (e.g., commutator stone or suitable abrasive strip – not random sandpaper grit)

- Soft brush or vacuum with HEPA/dust collection to handle carbon dust

- Feeler gauges and a dial indicator (for run-out checks on larger machines)

- Basic electrical test gear: multimeter at minimum; ideally insulation tester and, in a professional setting, bar-to-bar or motor circuit analysis equipment

4. The Commutator Repair Journey in Four Phases

Rather than think of “commutator repair” as one big scary task, break it into four logical phases:

- Inspection – understand exactly what’s wrong

- Cleaning & minor resurfacing – fix light contamination and slight roughness

- Machining & undercutting – for more serious wear or mechanical defects

- Reassembly, testing & brush run-in – make sure the fix actually works in the real world

Industrial best practices follow essentially this same sequence, just with more specialized machinery (precision lathes, undercutters, specialized test rigs) and tighter documentation.

- High-level process overview

- Inspect visually, mechanically (run-out), and electrically (basic checks)

- Decide: clean & dress vs send for turning/undercutting

- Restore a smooth, concentric, properly undercut commutator surface

- Match and seat brushes to the new surface; verify correct grade and tension

- Test under controlled conditions, watching temperature, noise, and sparking

Phase 1: Inspection – Listening to What the Motor Is Telling You

Good inspection prevents wasted effort. Before touching anything, look at the whole motor: environment, load, ventilation, and how hard the motor’s life has been. A “bad commutator” is often just the messenger for deeper issues like overload, poor ventilation, or drive problems.

Then focus in on the commutator and brushes:

- Visual inspection: look for discoloration, burnt spots, grooves, or heavily streaked copper. Dark, smooth “chocolate brown” is usually normal; blue or black burnt areas are not.

- Mechanical inspection (larger machines): check run-out with a dial gauge. Excessive out-of-roundness will cause brush bounce and uneven wear. Industrial repair specs often aim for run-out on the order of a few thousandths of an inch (≈0.05 mm), depending on size.

- Brush condition: uneven wear, chipping, or a heavy ridge matching a commutator groove all tell you about the “conversation” between brush and copper over time.

- Inspection checklist (before you commit to a repair approach)

- Is sparking light and uniform, or heavy and irregular?

- Are there obvious high bars, lifted segments, or cracks in the commutator?

- Does the commutator surface feel smooth (no deep ridges) when rotated by hand?

- Are brushes free in their holders, not sticking, with springs providing consistent pressure?

- Is there visible contamination (oil, dust, metallic particles) inside the motor?

- Has there been a recent overload, change in drive, or environmental issue (moisture, extreme dust)?

Phase 2: Cleaning & Minor Resurfacing

If your commutator is basically round, with no severe pitting or lifted bars, you may be able to restore it with careful cleaning and light dressing.

Start by removing loose contamination using a vacuum or soft brush – never aggressive compressed air that just redistributes conductive dust. Use a suitable electrical cleaning solvent and lint-free cloths to remove oil, grease, and sticky deposits, then let everything dry completely. Industrial guides emphasize that cleaning is a core maintenance activity, not an optional “extra.”

Minor surface roughness or light streaking can sometimes be improved with a proper commutator stone or approved abrasive strip, applied while the rotor is turning at low speed and with extreme care. The goal is to create a smooth, uniform surface – not to remove lots of copper.

- Cleaning do’s and don’ts

- Do use a vacuum or extraction system to manage carbon dust; treat it as harmful to both people and insulation.

- Do dry the motor thoroughly after solvent cleaning before re-energizing

- Do keep abrasives away from windings and bearings wherever possible

- Don’t use coarse sandpaper or emery cloth that embeds conductive grit in the copper

- Don’t remove visible amounts of material unless you’re intentionally machining the commutator

- Don’t ignore brush seating; after even mild dressing, brushes often need re-seating to the new surface

Phase 3: Machining, Undercutting & Finishing (For Serious Damage)

When the commutator is heavily grooved, out-of-round, or has high mica, a proper turning and undercutting operation on a lathe becomes necessary. Professional repair standards describe this as a precise machining process aimed at restoring:

- A smooth, concentric cylindrical surface

- Correct bar separation (mica undercut depth and width)

- Clean, burr-free edges on each bar

This is typically not DIY territory unless you have:

- A suitable lathe or in-situ commutator turning rig

- Correct tooling and undercutting equipment

- Experience with acceptable run-out and finish for the motor size

After turning, the mica between bars is undercut to a controlled depth, then the edges are chamfered and the surface carefully polished to remove burrs and metal slivers that could short bars. Industrial documents stress thorough post-machining cleaning to remove copper and mica dust before the motor ever sees voltage again.

- Typical mistakes during machining & undercutting

- Turning too aggressively, overheating the commutator and damaging insulation

- Leaving excessive run-out that accelerates brush wear and sparking

- Undercutting too shallow (mica left proud) or too deep (weakening bar support)

- Failing to deburr and polish after undercutting, leaving sharp edges that damage brushes

- Not thoroughly cleaning out copper and mica dust before reassembly

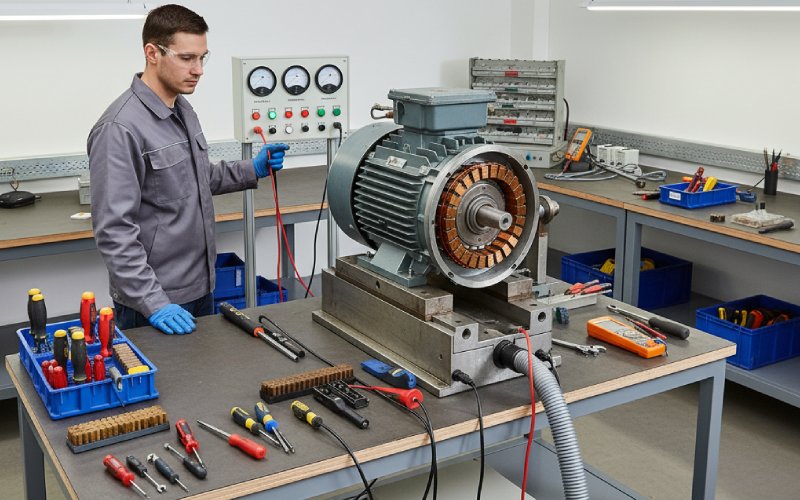

Phase 4: Reassembly, Testing & Brush Run-In

Once the commutator is restored, the job is only half done. Reassembly and testing determine whether your repair actually survives in service.

Reinstall brushes carefully, confirming the correct grade, size, and position. Industry articles repeatedly point out that many “commutator problems” are really brush selection or spring tension problems.

Brushes should be seated to the new surface – either by controlled running under light load or by carefully using a seating stone/abrasive on the stationary rotor, following OEM or brush supplier guidance. Then you perform controlled tests: insulation checks, no-load run, then gradual loading while monitoring temperature, vibration, and sparking.

- Essential tests after commutator repair

- Insulation resistance test between windings and ground before applying power

- No-load run: listen for unusual noise; watch for uneven sparking or excessive brush chatter

- Light-load test: monitor commutator temperature, brush contact pattern, and current draw

- Full-load trial (for industrial motors, ideally on a proper test stand)

- Post-test inspection: look for fresh tracking marks, brush edge chipping, or hot spots on the commutator

Troubleshooting: Symptoms, Causes & First Checks

You don’t have to memorize every failure mode, but it helps to have a mental map: symptom → likely cause → first check. Many recent resources on DC motor failures emphasize how heavily brushes and commutators feature in overall motor reliability.

Use the table below as a quick reference when you’re trying to decide whether you’re in “clean & monitor” territory or “shut down and plan a full repair” territory.

| Symptom (at commutator) | Likely Cause(s) | What to Check First | Safe Immediate Action* |

| Light, even sparking under all brushes | Often normal for DC machines | Brush grade vs OEM data, general cleanliness | Monitor; schedule routine cleaning |

| Heavy, irregular sparking on a few segments | High bar, loose bar, local contamination, winding fault | Visual inspection of those bars; check for lifted segments or burns | Reduce load, plan shutdown & professional test |

| Blue/black burnt band around commutator | Sustained overload, wrong brush grade, poor cooling | Load history, ventilation, drive settings | Reduce load; investigate cause before restart |

| Brushes wearing rapidly or unevenly | Wrong grade, incorrect spring tension, rough/out-of-round commutator | Brush data, spring settings, run-out measurement | Replace with correct brushes; dress or machine |

| Audible brush chatter and “ringing” at speed | Rough surface, incorrect tension, mechanical vibration | Surface finish, bearing condition, spring pressure | Stop, correct root cause before continued use |

| Visible tracking/black bands between bars | Contamination or conductive dust, moisture, poor cleaning | Cleanliness inside motor, environment (humidity, dust, oil) | Clean thoroughly; improve sealing/ventilation |

| Sudden flashover (arc across bars/brushholders) | Severe contamination, major winding fault, wrong settings, or serious damage | Insulation tests, physical damage, drive configuration | Immediate shutdown; professional repair only |

- “Safe immediate action” assumes you are already working within appropriate electrical safety procedures.

- Quick troubleshooting shortcuts

- If only one area of the commutator is misbehaving → suspect local bar or winding issues.

- If all brushes show similar problems → think environment, brush grade, load, or drive setup.

- When in doubt, compare brush/commutator contact patterns between “good” and “bad” motors of the same type.

- If you’ve already cleaned and checked brush tension and the problem persists → it’s no longer a “light maintenance” job.

Keeping It Healthy: Preventive Commutator Maintenance

The cheapest commutator repair is the one you never need. Maintenance organizations and motor reliability specialists strongly emphasize routine inspections and cleaning as the key to avoiding surprise commutator failures. Typical recommendations for many industrial motors range from monthly visual checks to more detailed quarterly inspections, adjusted for duty and environment.

Think in terms of three layers of care:

- Operator-level – listening, watching, and reporting unusual noise, odor, or sparking

- Routine maintenance – scheduled brush/commutator inspections, cleaning, and basic tests

- Periodic deep checks – more formal run-out checks, insulation tests, and detailed brush wear analysis in higher-duty applications

Closing Thoughts

A few practical questions come up all the time:

For small tools and hobby motors, cleaning, careful dressing, and brush replacement can meaningfully extend life if done patiently and safely. For larger industrial DC motors, the commutator is part of a much bigger reliability picture that includes field windings, cooling, drive tuning, and mechanical alignment – so commutator repair is usually one chapter in a professional overhaul, not a quick standalone fix.

If you remember nothing else from this article, remember this:

- Don’t ignore early signs (noise, sparking, odd smells) – the commutator is often your first warning.

- Separate light maintenance (cleaning, inspection, brush care) from true repair (turning, undercutting, bar replacement).

- When safety, size, or uncertainty are in play, involving a qualified motor repair shop is not a cost – it’s cheap insurance against long outages and repeat failures.

Use this guide as your mental map for electric motor commutator repair – to understand your options, to communicate better with repair shops, and to give your motors the smooth, spark-free life they deserve.