Does an AC Motor Have a Commutator?

If you’ve searched this question before, you’ve probably seen totally opposite claims:

- “AC motors never have commutators – only DC motors do.”

- “AC motors need a commutator to reverse current.”

- “Some AC motors have commutators… sometimes… sort of.”

No wonder people get confused.

Let’s clear it up properly:

- Most common AC motors (like those in fans, pumps, compressors, HVAC) do not have a mechanical commutator.

- Some special AC motors do use a commutator – most notably universal motors (e.g. drills, mixers, vacuum cleaners) and other AC commutator/repulsion types.

The rest of this article will explain exactly when an AC motor has a commutator, why most don’t, and how to tell what you’re looking at in the real world.

- Short answer:

- Standard AC induction and synchronous motors → No mechanical commutator (may use slip rings instead).

- Universal / AC commutator motors → Yes, they have a commutator and brushes.

- Brushless motors (BLDC / PMSM driven by inverters) → No mechanical commutator; they use electronic commutation in the drive circuitry.

Table of Contents

1. First: What Is a Commutator, Really?

Before we can say whether an AC motor “has one”, we need a precise picture of what we’re talking about.

In classical motor language, a commutator is:

- A rotating segmented copper cylinder on the rotor (armature).

- Stationary carbon brushes press on those segments.

- The segments are wired to armature coils so that, as the rotor turns, the commutator reverses the current in each coil at exactly the right angle.

The key point:

A commutator is not just “any rotating contact” – it’s a mechanical switch that repeatedly reverses rotor current to keep torque in the same direction.

- A commutator does these jobs:

- Flips the direction of current in rotor windings at specific positions.

- Keeps motor torque mostly unidirectional, so the shaft doesn’t vibrate back and forth.

- Works together with brushes and segmented copper bars.

- Is most famously used in DC motors and universal motors.

2. Commutator vs Slip Rings vs “Electronic Commutation”

A big source of confusion online is that people blur three different things together:

- Mechanical commutator (segmented, switching / reversing current)

- Slip rings (continuous, no reversing)

- Electronic commutation (done by power electronics)

Let’s sort them out.

In slip rings, you have:

- Smooth continuous rings mounted on the rotor shaft.

- Brushes resting on those rings.

- Purpose: transmit AC or DC into the rotor without reversing the current periodically – just a continuous connection.

This is what you see in:

- Wound-rotor (slip-ring) induction motors – where external resistors are added via slip rings for speed/torque control.

- Many synchronous motors, where slip rings feed DC field current to the rotor.

Slip rings ≠ commutator. The shape looks similar from far away, but the function is totally different.

- Quick mental checklist:

- Segmented copper cylinder, lots of “slices”, clearly not smooth? → That’s a commutator (reverses current).

- A few smooth metal rings with brushes on them? → Those are slip rings (continuous connection, no switching).

- No rings, no brushes, just three thick cables into a sealed motor + an inverter drive? → That’s probably brushless / electronically commutated. The “commutation” happens in the electronics, not inside the motor.

3. So… Which AC Motors Actually Use Commutators?

Now we can tackle the core question properly.

AC motors are a big family. High-level, you can group them as:

- Induction motors (squirrel cage & slip ring)

- Synchronous motors (permanent magnet, reluctance, DC-excited, etc.)

- AC commutator motors / universal motors

Let’s put the commutator question into a compact comparison table.

Quick Reference Table – Do These Motors Have a Commutator?

| Motor Type | Supply Type | Mechanical Commutator? | Slip Rings? | Typical Uses |

| Brushed DC motor | DC | Yes | No | Toys, small drives, old tools |

| AC induction – squirrel cage | AC | No | No | Fans, pumps, compressors, conveyors |

| AC induction – wound rotor (slip ring) | AC | No | Yes (for rotor circuit) | Cranes, hoists, heavy starting torque |

| Synchronous motor – DC excited | AC (stator) + DC (rotor) | No | Often yes (for rotor DC field) | Large industrial drives, power factor correction |

| Universal / AC commutator motor | AC or DC | Yes | No | Drills, mixers, vacuum cleaners, small tools |

| Repulsion / other AC commutator types | AC | Yes | No | Older / niche AC machines, high starting torque |

| Brushless DC (BLDC) / PMSM | AC from inverter | No (electronic commutation) | No | EVs, modern appliances, high-efficiency drives |

- In everyday language:

- The AC motors in most household fans, pumps, and industrial machines are induction or synchronous motors → no commutator.

- The screaming motor in your cheap drill, blender, vacuum cleaner, hair dryer is usually a universal motor → yes, it has a commutator and brushes, even though it’s plugged into AC.

4. Why Most AC Motors Don’t Need a Commutator

A classic brushed DC motor needs a commutator because the supply is DC, but we still want a rotating magnetic field inside the machine. The commutator mechanically “chops and rearranges” that DC so that, from the rotor’s point of view, the magnetic field keeps trying to push it around in a circle.

AC motors cheat (in a good way):

- With an AC supply, the voltage and current are already alternating.

- Arrange the stator coils correctly (especially in 3-phase) and that alternating current naturally produces a rotating magnetic field – no mechanical switching needed.

- In an induction motor, this rotating field induces current in the rotor bars or windings, automatically giving you the required torque direction without a commutator.

So instead of “brute-forcing” commutation mechanically, AC motors rely on physics + winding layout + the AC waveform itself. That’s why:

- Articles from motor manufacturers emphasize that brushes and commutators are not necessary in typical AC motors and that this makes them simpler and more reliable.

- Why designers avoid mechanical commutators in AC machines when they can:

- Maintenance: Brushes and commutators wear out and need cleaning/replacement.

- Sparking & EMI: The switching contacts generate electrical noise and sparks.

- Efficiency & heat: Losses at the brushes and commutator reduce efficiency.

- Mechanical limits: Commutators limit maximum speed and size.

- Cost & robustness: A plain squirrel-cage rotor is almost bulletproof; a commutator is intricate and fragile by comparison.

In short: if an AC motor can be built without a commutator, it almost always is.

5. The Special Case: Universal / AC Commutator Motors

So why do some AC motors still use commutators?

Enter the universal motor (also called an AC commutator motor or AC series motor).

Construction-wise, it’s basically a series-wound DC motor with a commutator, tweaked so it can run on AC:

- The stator field winding and rotor (armature) winding are connected in series through the commutator.

- When the AC reverses, both field and armature currents reverse together, so the torque still points the same way.

- The commutator keeps the torque direction consistent as rotor coils pass different poles.

What you get is a motor that:

- Can run on either AC or DC (hence “universal”).

- Has very high starting torque and can reach high speeds (10,000–30,000 rpm or more in tools).

- Is relatively compact and cheap, but:

- Noisy, less efficient, and high maintenance due to brush and commutator wear.

- You’re probably dealing with a universal (AC commutator) motor if:

- The appliance is small, handheld or compact.

- It screams at high RPM (drills, blenders, grinders, hair dryers, some older washing machines).

- Opening it up, you see:

- Carbon brushes,

- A segmented commutator,

- Laminated stator with wound field coils.

That’s an AC motor with a commutator – the main (and very important) exception to the “AC motors don’t have commutators” oversimplification.

6. Why Some Sources Say “AC Motors Need Commutators”

If you browse around, you’ll find some pages saying things like:

“AC motors need a commutator; the commutator is usually a rectifier,”

…or claiming that only DC motors have commutators and therefore all AC motors are commutator-free.

What’s going on here?

Two common mix-ups:

- Mixing mechanical and electronic commutation

- In brushless motors (BLDC / PMSM), the inverter or drive electrically “commutates” the phases.

- Some authors loosely call this “the commutator”, even though there’s no mechanical commutator in the motor at all – just semiconductor switches in the drive.

- Ignoring the universal motor family

- Some simple “DC vs AC” comparison pages say:

DC motors → have commutators AC motors → don’t have commutators - This is true for induction and many synchronous motors, but explicitly wrong for universal / AC commutator motors.

- Some simple “DC vs AC” comparison pages say:

So, the more precise statements are:

- “Most industrial AC motors are commutator-less (though some use slip rings).”

- “Some AC motors (universal / AC commutator / repulsion) do have a mechanical commutator.”

- “Many modern AC drives use electronic commutation instead of a mechanical commutator.”

- When you see contradictory claims online, ask yourself:

- Are they talking about mechanical hardware inside the motor, or electronic switching outside it?

- Are they ignoring universal / AC commutator motors, or explicitly excluding them?

- Are they confusing slip rings with commutators?

Once you separate those, the picture becomes much cleaner.

7. Practical Takeaways (For Buyers, DIYers, and Students)

Let’s end with what you can actually do with this knowledge.

- If you’re choosing a motor for a project:

- Need simple, low-maintenance, long-life? → Choose an induction motor or a PMSM/BLDC with a good drive (no commutator).

- Need small size + high speed + high starting torque, and don’t mind noise/maintenance? → A universal / AC commutator motor might be appropriate (think power tools).

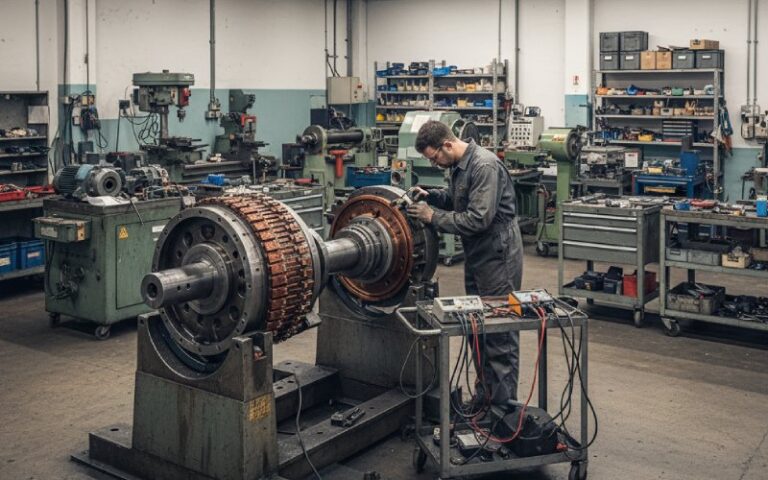

- If you’re troubleshooting an appliance motor:

- See brushes + segmented copper cylinder? → Expect brush wear, commutator pitting, arcing to be common failure points.

- See no brushes, just a sealed frame with a fan on the end? → It’s likely an induction or brushless motor; look instead at bearings, capacitor (for single-phase), or the drive electronics.

- If you’re studying for exams:

- Memorize the core idea:

- DC motor → commutator.

- AC induction & synchronous → no commutator; sometimes slip rings.

- Universal motor → AC or DC, but always has a commutator.

- Be ready to explain why:

- DC needs mechanical commutation; AC stator fields do it “for free”.

- Memorize the core idea:

8. Final Answer in One Sentence

Most AC motors you encounter (induction and synchronous types) do not have a mechanical commutator, but a special subset – universal and other AC commutator motors – absolutely do.

Once you keep that split in mind, all the conflicting articles online suddenly stop being confusing and start looking like what they are: simplified views of a much richer picture.