DC Generator Commutator

The commutator in a DC generator functions as a mechanical rectifier that transforms the alternating EMF induced in the armature windings into a unidirectional DC output for the external circuit. Constructed from wedge-shaped copper segments insulated by mica and mounted on a steel hub, it connects to the armature coils and utilizes carbon brushes to collect current while switching connections as the rotation passes the magnetic neutral axis. Ultimately, whether referred to as a dynamo, split ring, or generator commutator, the quality of its construction is the critical factor that dictates sparking behavior, brush longevity, and the overall reliability of the DC machine.

DC Generator Commutator Manufacturer in China

As a leading commutator manufacturer in China, XDC specializes in high-performance dc generator commutator solutions for industrial plants, marine power, traction systems and repair shops worldwide. From compact pump drives to multi-meter dynamo sets, we design and manufacture complete generator commutator assemblies that deliver stable DC output, low sparking and long service life.

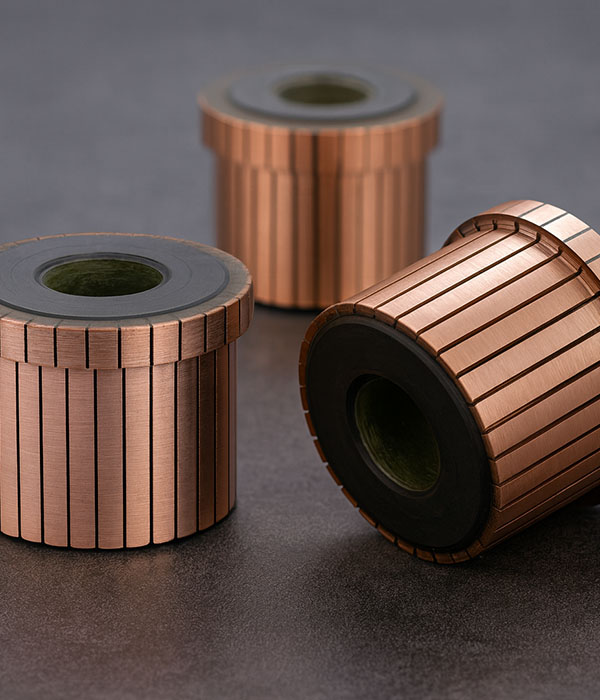

DC Generator Commutator Manufactured by XDC

See how XDC supports the power generation sector with custom DC generator commutators. We are dedicated to fabricating components that match your technical prints, validating quality through samples before launching into volume production. Review our track record below to understand our manufacturing precision, and directly send us your drawings to get a quote.

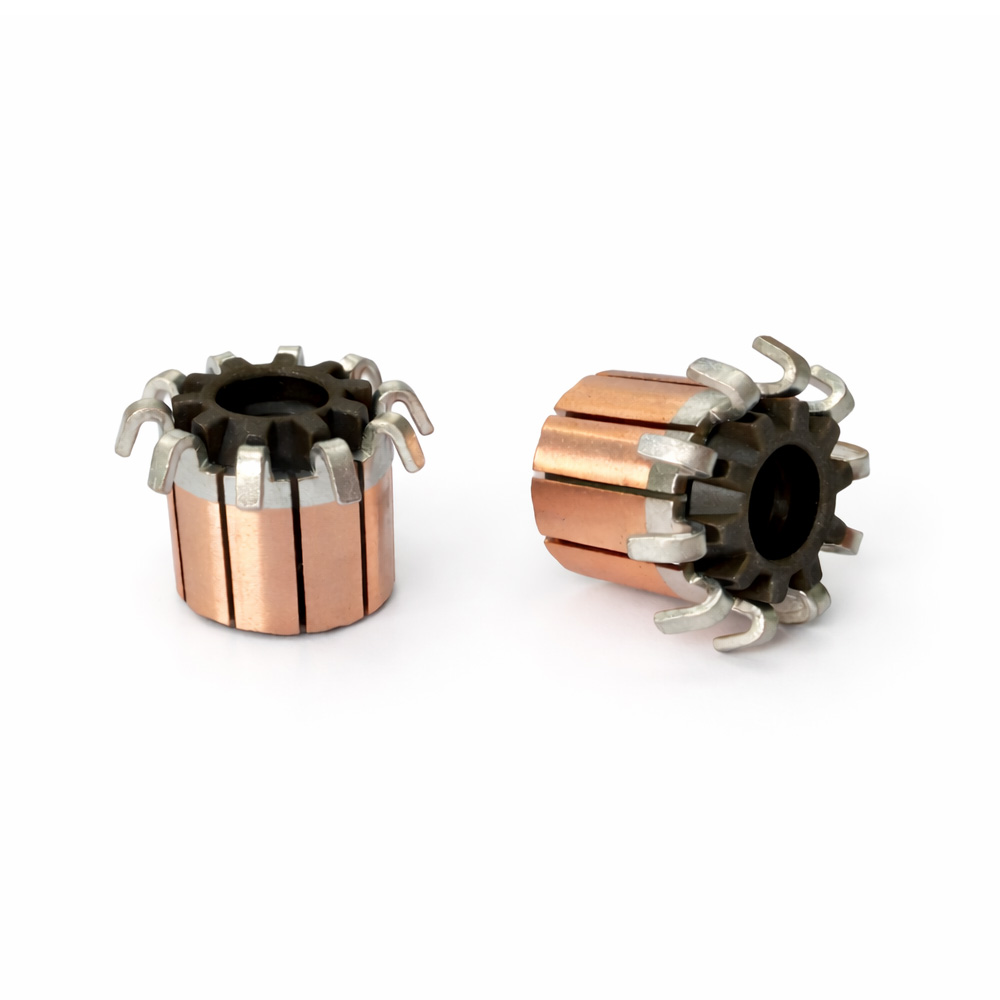

15.2mm Commutator

Engineered specifically for DC power generation, this 10-segment component functions as a precise mechanical rectifier. Its design maximizes rectification efficiency and ensures stable voltage output with minimal ripple.

Precision 14-Bar Commutator

Featuring a high-density 14-segment layout, this 11.4mm component offers superior rectification resolution. It delivers smoother DC voltage output with significantly reduced ripple for precision generator applications.

15mm Generator Commutator

Optimized for power generation, this 10-segment unit facilitates efficient current extraction from the armature. Its 15mm OD provides a durable contact surface for consistent electrical output under load.

7mm Generator Commutator

Engineered for miniature DC generators, this 5-segment unit ensures efficient electromechanical conversion. Its odd-numbered slot configuration helps reduce magnetic cogging, allowing for smoother shaft rotation and stable output.

15.2mm DC Generation Commutator

With a 10-segment configuration and 15.2mm OD, this unit is engineered for stable current collection. It ensures low contact resistance and durability during the continuous mechanical rectification process.

6-Slot Micro Generator Commutator

Functioning as a precision mechanical rectifier, this 6-segment, 6.5mm unit improves output waveform quality. It significantly reduces voltage ripple compared to standard 3-slot designs in miniature power generation.

5-Segment Generator Commutator

Designed to minimize mechanical resistance, this 5-slot unit prevents magnetic locking (cogging). It ensures easy startup and smooth operation for high-efficiency micro DC power generation.

3-Bar Generator Commutator

Featuring reinforced right-angle tangs, this 3-segment unit ensures secure winding connections under stress. It provides reliable basic rectification for rugged DC power generation applications where durability is paramount.

Why Choose XDC as Your Commutator Partner?

Choosing the right dc generator commutator supplier can make the difference between constant maintenance and years of reliable service.

1. Focused expertise in DC machines

XDC is not a general-purpose machine shop but a dedicated specialist in dynamo and motor/generator commutators, utilizing a deep understanding of lap and wave winding patterns, interpoles, and armature reaction. Our engineering team leverages this system-level knowledge—ranging from brush grade selection to neutral point setting—to fine-tune each DC generator commutator for optimal real-world commutation behavior rather than simply meeting dimensional specifications.

2. Comprehensive product range

We offer a singular platform covering V-ring, molded, dovetail, and slot-type designs suitable for applications ranging from small auxiliary units to large multi-MW machines. With an extensive inventory of cross-referenced part numbers matching major OEM DC generators and dynamos, we enable quick, "drop-in" replacements for a wide variety of equipment.

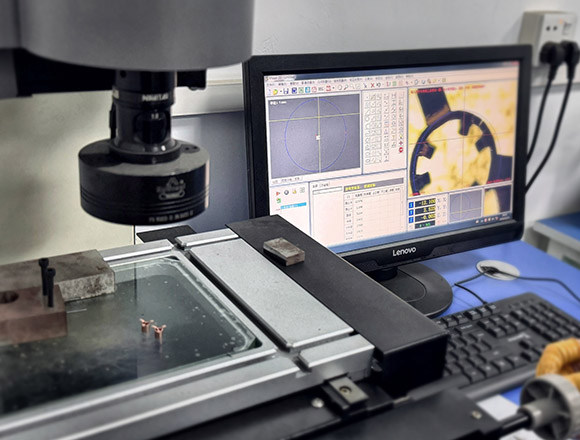

3. Proven quality and testing

Our manufacturing processes align with recognized rotating-machine practices and established design guidelines, ensuring that every DC generator split ring or segmented unit undergoes routine electrical testing. Furthermore, we perform dynamic balancing of rotor and commutator assemblies to guarantee smooth operation and reliability even under high peripheral speeds.

4. Lifecycle support

We provide comprehensive support spanning the entire product lifecycle, from initial selection to after-sales service. This includes engineering assistance for determining bar counts and hub details for new designs, as well as expert guidance on brush setup, mica undercutting, and skim-cut intervals to maximize the service life of your generator’s commutator.

Key Features & Technical Highlights

At XDC, every commutator in dc generator service is engineered from the ground up for demanding industrial duty.

Wide diameter and design range

From compact units to multi-meter commutators for large DC generators and traction sets, we cover the full size range.

Available as:

- V-ring commutators – copper bars on a steel core, clamped with insulated steel V-rings and mica cones, ideal for large machines and heavy shock loads.

- Molded / dovetail commutators – with reinforced thermoset molding for stable dimensions at temperature and speed.

- Slot / segment commutators – reinforced hook feet and copper bush for high-speed and overspeed-critical machines.

This flexibility lets us tailor each dc generator split ring commutator or multi-segment design precisely to your application.

Premium materials and insulation system

- Hard-drawn (or silver-bearing) copper bars for high conductivity and increased annealing temperature.

- Segment mica between bars and molding mica for V-rings and sleeves ensure excellent dielectric strength and thermal stability.

Hubs and spiders in stainless steel or cast iron for mechanical strength and dimensional stability in continuous-duty dynamo commutator applications.

Electrical performance range

- Suitable for industrial and marine DC generators used in propulsion, excitation and auxiliary systems.

- Compatible with shunt, series and compound DC machines, as well as classic dynamo commutator configurations.

- Insulation systems designed to meet or exceed common PI (polarization index) and megohm criteria used in shipboard and plant maintenance standards.

Installation & Maintenance Advantages

When you install an XDC generator commutator, you also get predictable maintenance over its life:

Easy fitment

Machined bores, keys and shoulders matched to your shaft, with clear instructions for shrink fits or clamped assemblies.

Optimized commutator surface

Polished tracks ready for brush seating; recommended brush coverage and pressure given for your frame size.

Service-friendly design

V-ring and mechanical assemblies designed for future refilling, with sufficient bar depth for several skim cuts before replacement.

Typical Applications & Usage Scenarios

Because the commutator in dc generator machines is the heart of DC conversion, XDC designs each product for real-world duty:

Industrial DC generators

rolling mills, crane and hoist drives, mining winches, DC drives, excitation systems.

Traction and transportation

large generator commutator sets in traction vehicles and auxiliary train supplies.

Pumps and auxiliaries

DC pump drives, auxiliary motor–generator sets and standby dynamo systems.

Marine and offshore

shipboard DC propulsion, bow thrusters, and excitation generators in harsh salt-laden environments.

Contact Us Now

Ready to upgrade or replace your dc generator commutator?

Get in touch with XDC today:

- Send us your existing part number and dc generator commutator diagram.

- Or ship us a sample dynamo commutator / generator commutator for reverse engineering.

XDC – China’s professional partner for high-reliability commutator solutions. We’re ready to support your next DC generator project, from first design to long-term maintenance.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

Frequently Asked Questions (FAQ)

The commutator function in dc generator machines is to act as a mechanical rectifier. As the armature rotates, it reverses the coil connections at the precise moment they pass the neutral axis, so the output at the brushes always flows in one direction. In other words, the commutator of a generator converts the internally induced AC in the armature into DC at the terminals.

The purpose of commutator in dc generator construction is twofold:

- Connect rotating armature conductors to the stationary external circuit via carbon brushes.

- Ensure that the load current remains unidirectional, even though the induced EMF in each coil is alternating.

A well-designed dc generator commutator improves efficiency, reduces sparking and extends brush life.

The use of commutator in dc generator machines is fundamentally different from slip rings used in alternators. Slip rings transfer pure AC from the rotor; a dc generator split ring commutator or multi-segment commutator actually rectifies the voltage as it transfers current. That’s why classic dynamos and many older DC generators use commutators instead of slip rings.

Absolutely. XDC regularly designs dynamo commutator and custom generator commutator units to customer drawings or samples. We can adapt bar count, diameter, hub material, ventilation and riser style to match your electromagnetic design and duty cycle.

Yes. We have experience supplying dc generator commutator assemblies for shipboard and offshore applications where vibration, moisture and salt contamination are common. Designs emphasize robust insulation systems, high mechanical strength and easy field maintenance to comply with typical marine overhaul practices.

If the hub, shaft and basic geometry are intact, we can often refill or resegment the existing assembly—replacing copper bars and mica while keeping the core. This can be faster and more economical than full replacement, especially for large V-ring generator commutator units. Where damage is extensive or the design is obsolete, we recommend a new XDC assembly.

Latest from Blog

Our blog content will provide you with a wealth of information and inspiration. They not only reflect our expertise and experience, but also encourage you to explore and discuss relevant topics with us.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…