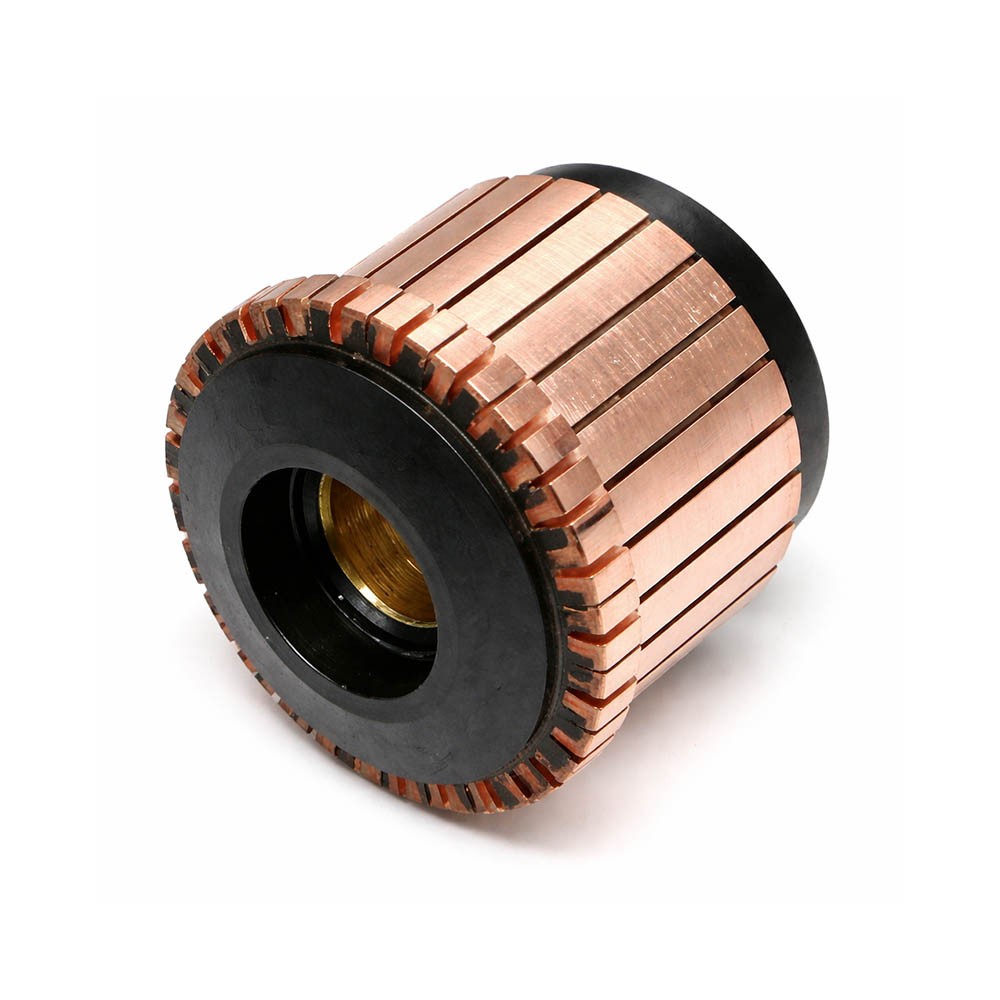

Copper Commutator

An XDC copper commutator is built around precision-machined copper segments separated by high-grade mica insulation and bonded to a rigid hub and armature shaft interface. We optimize brush contact geometry, segment concentricity, and surface finish to maintain low contact resistance and smooth current transfer between carbon brush and commutator bars.

Copper Commutator Manufacturer in China

At XDC, we specialize in designing and manufacturing high-performance copper commutator assemblies for DC motors, universal motors, traction motors and DC generators across demanding industries worldwide. Combining premium electrolytic and oxygen-free copper with advanced mica insulation, precision machining and dynamic balancing, we deliver stable commutation, low brush wear and long service life even under harsh load and climate conditions.

Copper Commutators We've Manufactured

Witness XDC’s range of high-grade copper commutators, built for maximum conductivity and thermal efficiency. We focus on fabricating parts that align perfectly with your mechanical layouts, ensuring quality with first-article units before moving into full-scale manufacturing runs. See our high-purity copper solutions below, and directly send us your drawings to get a quote.

Precision-Slotted 10-Bar Commutator

Featuring high-precision segment undercutting, this 15mm unit prevents carbon buildup and ensures reliable arc suppression. The 10-bar architecture is optimized for consistent electrical switching in industrial-grade motor applications.

High-Resolution 6-Bar Commutator

With a 6.5mm OD, this 6-segment unit doubles the commutation frequency relative to 3-slot designs. It stabilizes the current waveform and minimizes torque ripples for precision micro-motor drives.

High-Conductivity 3-Bar Commutator

Engineered with high-purity copper for minimal power loss, this 3-bar right-angle unit provides superior conductivity. Its reinforced anchoring system prevents bar-lifting at high RPMs, ensuring sustained mechanical integrity.

16-Segment Face Commutator

Designed with high-precision radial segment alignment, this 47.6mm unit optimizes electrical bridging. Its structural uniformity prevents uneven brush contact patterns, ensuring consistent commutation performance in low-profile industrial motor assemblies.

7.6mm Heavy-Wire Commutator

The 3-segment geometry on this 7.6mm unit provides increased spacing for heavy-gauge wire attachment. It is physically optimized to support high-torque motor windings requiring robust electrical connections.

Precision 5.6mm 5-Bar Commutator

Engineered to prevent copper segment bridging, this 5.6mm unit maintains critical insulation gap integrity. The 5-segment layout ensures stable current switching and long-term electrical reliability in precision micro-drives.

High-Stiffness 3-Bar Hook Commutator

Features rigid bent hooks with high deflection resistance to maintain contact integrity under extreme thermal cycles. Optimized for micro motors requiring high-current durability and stable mechanical wire retention.

Industrial 28-Bar Commutator

Reinforced to resist centrifugal displacement, this 42mm unit maintains exact segment height uniformity. Its robust architecture prevents “high bar” defects, ensuring long-term mechanical stability in heavy-duty industrial machines.

XDC’s Technical Features

Materials & Conductivity

High-purity electrolytic copper or oxygen-free copper for low contact resistance and excellent thermal conductivity. Optional silver-bearing copper segments for very high current density or demanding duty cycles

Insulation System

Mica-insulated commutator bars with resin-impregnated slots for high dielectric strength. Insulation systems selected for the temperature class of your DC motor or generator

Custom Engineering

Matching to your armature core and armature winding data (segment count, riser design, lead connection). Shaft bore, keyway and hub geometry customized for your rotor shaft and fit requirements

Precision Machining & Balancing

Lathe-turned or ground surfaces to achieve a smooth, uniform finish with controlled surface roughness. Dynamic balancing on a precision balancing machine for low vibration at high RPM. Tight control of runout and concentricity to minimize brush chatter and noise

Brush Interface Optimization

Compatibility with carbon brushes, graphite brushes and metal-graphite grades. Recommendations on spring pressure and brush grade to avoid threading, grooving, copper drag and flashover

Why Choose XDC

Partnering with XDC means lower total cost of ownership: fewer unplanned shutdowns, longer intervals between brush changes, and more stable motor performance.

Specialized focus

XDC is dedicated to commutator technology. Our team has extensive expertise in commutator segment design, brush contact optimization, and DC motor commutation.

Advanced manufacturing

Precision machining, CNC undercutting, fine turning and grinding, and strict process control ensure consistent geometry, low runout, and excellent surface finish.

Comprehensive testing

From insulation resistance and bar-to-bar testing to dynamic balancing and visual surface grading, every unit leaving our factory is validated against demanding criteria.

Global support

As a leading Chinese manufacturer, XDC supplies commutators to customers across Asia, Europe, and the Americas, offering technical support and fast lead times.

Applications of Copper Commutators

An XDC commutator is the heart of many critical rotating machines, including:

Industrial DC drives

Industrial DC drives for rolling mills, hoists, cranes and winches

DC Generators and Dynamos

DC generators and dynamos in power, marine and backup systems

Universal motor drives

Universal motor drives in power tools, vacuum cleaners and household appliances

Traction motors & DC motors

Railway traction motors and auxiliary DC motors

Starter Motors & Auxiliary Drives

Automotive starter motors and various auxiliary drives

Contact Us

Ready to upgrade your DC or universal motor with a high-performance copper commutator from XDC?

Please provide your commutator drawings and inform us of any additional requirements for the product, and we will recommend an optimized design including segment count, dimensions, brush grade, and operating limits. Whether you require a single prototype or high-volume OEM production, XDC is ready to support you.

Get in touch with XDC today to discuss your project, request a quotation or schedule a technical consultation with our application engineering team.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Copper Commutators from XDC

Generally, you only need to provide your commutator drawings. We will evaluate based on the data included in your drawings and provide you with a quote

Service life depends on load, brush grade, cooling and environment. Under recommended current densities (≈12–30 A/cm²) and well-controlled humidity and temperature, a quality copper commutator can run for many thousands of hours. In hot, humid and heavily loaded conditions, wear can increase by several times, so more frequent inspections are necessary.

Yes. We design commutators for peripheral speeds up to around 35–40 m/s on the brush track, depending on brush material and mechanical constraints. For very high speed universal motors, we pay special attention to dynamic balancing, hub strength and tribolayer stability.

A commutator uses insulated copper segments to mechanically rectify AC in the armature winding into DC at the terminals (or vice versa), while slip rings provide a continuous connection to AC windings without segmenting. For DC machines and universal motors, a copper commutator is essential for correct commutation; slip rings are used on AC machines such as wound-rotor induction motors and synchronous machines.

If you have further questions or need a custom design, please contact XDC and our team will gladly assist.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…