Commutator Turning Service

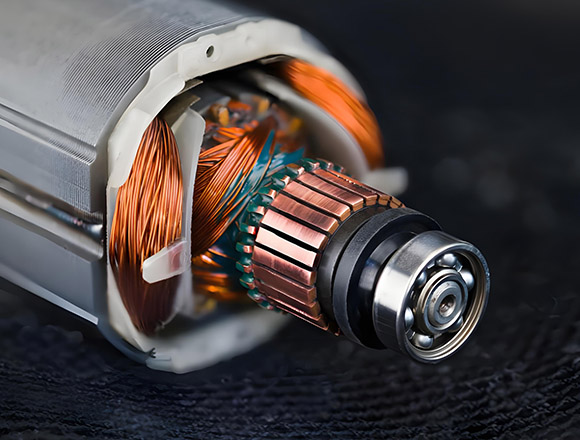

At XDC, we specialise in precision commutator turning for demanding DC and universal motor applications. As a leading custom commutator manufacturer in China, we combine advanced PCD tooling, dedicated CNC lathes and strict in-process control to deliver stable, repeatable surfaces on every copper commutator we machine.

Every job, whether it is a new custom part or a refurbishment, is handled as a critical precision operation. We focus on geometry, finish and cleanliness so your finished commutators support quiet running, low sparking and consistent brush wear in the field.

Precision Commutator Turning Services for Custom Commutators

Our factory is equipped with dedicated automatic lathes configured specifically for commutator work. These machines use servo-driven diamond cutters and servo-driven workpiece rotation, controlled through colour LCD interfaces for precise setup.

For repeat projects, our equipment can store and encrypt up to 100 sets of machining parameter programs, including speeds, feeds and target dimensions. That means:

- The first and the thousandth piece in a batch are produced to the same recipe.

- Refurbishment jobs can be duplicated accurately months or years later.

Why choose XDC for commutator turning

Choosing a partner for commutator turning is about more than simply owning a lathe. It is about process, measurement and experience. XDC offers:

1. Documented machining parameters

Our internal standards define clear windows for:

• Depth of cut

• Cutting speed and feed

• Target surface roughness and tolerance

Technicians work to parameter sheets rather than guesswork. Critical jobs are logged and can be traced back through program records and inspection data.

2. High-end equipment and tooling

By using PCD and diamond-tipped tools designed for commutator work, we achieve:

• Bright, uniform copper surfaces

• Low cutting forces that protect the segments

• Stable tool life over long batches

3. Metrology and inspection

After machining, we routinely check:

• Diameter, roundness and taper

• Surface roughness of the brush track

• Insulation slot condition and edge preparation

Inspection reports can be provided as part of your quality documentation when needed.

4. Flexible batch sizes

From single prototypes to large series, we can scale capacity while maintaining the same quality standard. You receive consistent results whether you order ten pieces or several hundred.

Key machining capability highlights

We keep our capability data transparent so you can match your design to our process window:

- Length range: typically 75 mm to 450 mm for standard fixtures, with customised tooling available for special geometries.

- Roundness / ovality: finished ovality held to within 0.015 mm or better when the incoming part condition allows.

- Surface roughness: typical copper brush track roughness of about 1.0–1.5 µm Ra, aligned with widely accepted practice for DC commutators.

- Profile and taper: controlled across the full width of the track, verified at multiple positions.

- Insulation slot work: undercutting below the copper surface, followed by beveling and chamfering of bar edges and careful deburring.

These values are not theoretical; they are the real specification targets our technicians work to every day.

Advanced tooling for commutator turning

To maintain high quality over long production runs, XDC uses polycrystalline diamond (PCD) and other diamond-tipped tools optimised for commutator turning and fine finishing.

Typical cutting data within our standard process windows include:

- Depth of cut: around 0.02–0.15 mm for finishing passes, adjusted to suit the wear pattern and final size requirement.

- Cutting speed: generally 200–600 m/min on copper, balancing surface brightness against tool life.

- Feed rate: typically 0.04–0.08 mm per revolution during finishing.

For special surface or profile requirements, we select tools with fine tip radii, for example:

- Nominal tip radius about 0.2 mm for robust finishing

- Ultra-fine options down to roughly 0.025 mm when a very gentle cut is required

Where geometry correction is needed, we work to controlled stock-removal guidelines, often in the order of 0.12–0.25 mm per side in several light passes. This approach corrects the profile without overstressing the copper segments.

Usage scenarios for your commutator

Because XDC is both a custom commutator manufacturer and a precision machining provider, we support a wide range of practical use cases:

New custom production

After forming, machining and assembly, we apply a final precision finish so the commutator leaves our factory at its exact drawing diameter, roundness and brush track texture.

Process optimisation for OEMs

For repeating models, we lock optimised programs into our machine memory. Every new batch is produced to the same stored parameters, simplifying your quality approvals.

Support for demanding industrial applications

Our fixtures and equipment allow us to handle both small precision units and large industrial commutators with the same focus on geometry, finish and traceability.

How our service works

To keep results predictable, we follow a structured process from enquiry to finished part:

- Requirement review You send us drawings, specifications and, if available, photos of the current condition. We confirm feasibility and recommend a machining plan.

- Incoming inspection Each part is checked visually and dimensionally to determine the required material removal, finish and slot work.

- Fixturing and alignment The commutator is mounted and aligned to its reference surfaces so all corrections are made relative to the true running axis.

- Rough and semi-finish cuts Where needed, controlled passes remove heavy damage or deep grooves while staying within agreed stock-removal limits.

- Finish machining Light passes, using the defined speeds and feeds, bring the surface to its final diameter and roughness range.

- Undercutting and edge preparation Insulation between segments is recessed below the copper level, and bar edges are chamfered and deburred to avoid sharp corners that could chip brushes.

- Final inspection and cleaning We re-measure critical dimensions and surface quality, then clean each part to remove chips and fine dust before packing or further processing.

Because programs and parameters are stored, the same part number can be run again later with matching results.

Quality assurance for every machined commutator

Quality in this process is measured, not assumed. At XDC we:

- Align finishing targets for the brush track with widely accepted practice unless you specify otherwise.

- Monitor roundness and taper so the track is truly cylindrical within the agreed tolerance band.

- Verify insulation undercut depth and bar edge chamfer against internal standards.

- Use calibrated gauges and controlled procedures so every technician follows the same workflow.

If your project demands tighter tolerances or a special roughness range, we can adjust the machining parameters and inspection plan accordingly.

Contact us for commutator turning services

If you need reliable, data-driven commutator turning services from a specialist in China, XDC is ready to support you.

When you contact us, please provide:

- Technical drawing

- Target dimensions after machining

- Requirements for insulation undercutting, beveling and chamfering

- Preferred surface roughness range for the brush track

- Expected batch size and delivery schedule

Our engineering team will review the information, choose the optimal machining route and provide a clear quotation and lead time.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ about commutator turning

Material removal is kept as low as possible to preserve segment integrity. In many cases we work within controlled ranges such as about 0.12–0.25 mm per side, split into several light passes. The exact value depends on the initial wear or damage and the final size you specify.

Yes. Our automatic equipment can store up to 100 sets of parameter programs. For recurring models, we fix the same speeds, feeds and target dimensions so future batches match your approved samples.

For most DC applications we target a copper surface roughness of roughly 1.0–1.5 µm Ra, which provides a good balance between fast brush seating and long-term stability. If your application needs a smoother or slightly rougher track, we can adjust finishing passes to hit your range.

XDC is a leading custom commutator manufacturer in China. We can supply complete, newly manufactured components finished in our factory, or provide machining as a standalone service for commutors you supply.

For production batches we combine stable PCD tooling, locked parameter sets and in-process checks. Sample pieces are measured at defined intervals, and any drift is corrected immediately, keeping every piece within your agreed specification.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…