Commutator Replacement: A Deep, Practical Guide to Saving Your DC Motors

If a motor in your plant or workshop is misbehaving, the commutator is often the quiet villain in the background. It’s small, hidden, and usually ignored…right up until the day you smell burning insulation or see a spray of sparks under the brush rigging.

This guide is written so that non-motor-specialists (maintenance managers, reliability engineers, serious DIYers) can talk to motor shops and vendors from a position of real understanding—not guesswork and Google fragments.

We’ll walk through what a commutator actually does, when it can be repaired vs when it must be replaced, what replacement involves, what it costs, and how to avoid needing it again any time soon.

Table of Contents

1. First Things First: What Is the Commutator, Really?

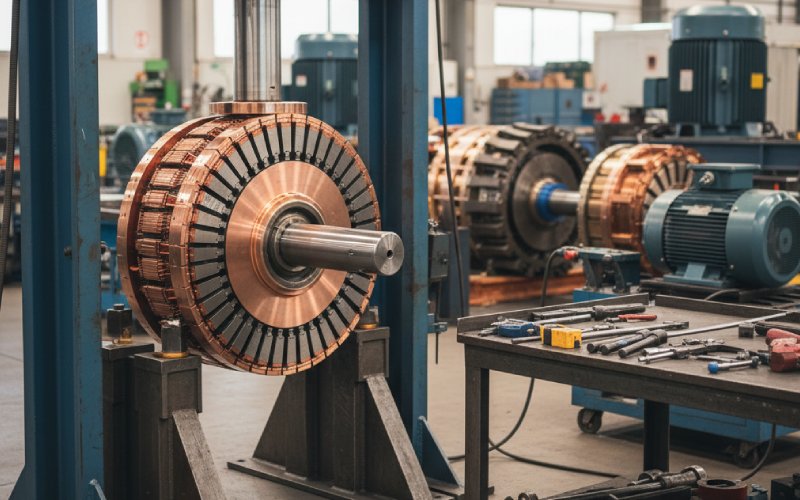

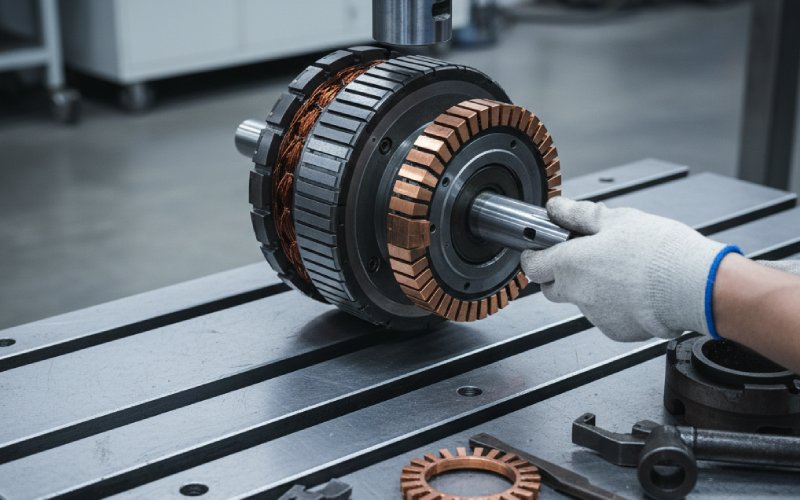

In a brushed DC motor, the commutator is the copper cylinder on the rotor that the carbon brushes ride on. It’s made of many copper bars (segments) insulated from each other and connected to the armature windings. Its job is to reverse current in the windings at exactly the right time, so torque keeps pushing in the same direction and the motor spins smoothly.

When the commutator is healthy, you barely think about it. When it isn’t, everything else suffers—brushes burn up, windings overheat, and vibration skyrockets.

Key roles of the commutator:

- Keeps torque in the same direction by reversing current at the right rotor position

- Provides the sliding electrical contact surface for the brushes

- Strongly influences brush life, heat generation, and overall motor efficiency

2. Is Your Commutator Actually the Problem? Key Symptoms to Look For

You don’t need to be a motor guru to spot commutator trouble. A flashlight, some patience, and your senses go a long way.

Common visual symptoms described in industrial repair literature include:

- Grooving – smooth circular trenches along the brush path

- Streaking – thin dark lines in the brush track

- Threading – ultra-fine lines that look like threads, often linked to rapid brush wear

- Photographing – broad dark tracks as wide as the brush face

- Marking / Burning of bar edges – every few bars darkened or burnt, often pointing to uneven current or misaligned brushes

- Copper drag / smeared copper – the surface looks like it’s been melted and wiped

Operational symptoms that often accompany those visuals:

- More sparking than usual at the brushes

- Ozone or “burnt” smell near the motor

- Noticeable drop in torque or speed under the same load

- Excessive brush dust, frequent brush changes

- Rising motor temperature or tripped overloads

Quick Symptom–Cause–Action Table

Below is a compact decision aid you can adapt straight into your blog or maintenance manual:

| Symptom on Commutator | What It Looks Like | Likely Root Causes | Typical Action (If Caught Early) | When Replacement Becomes Likely |

| Grooving | Smooth circular grooves along brush path | Wrong brush grade, low spring pressure, dry/dirty environment | Correct brush grade & pressure, light machining and undercut | If diameter now below minimum or bars badly weakened |

| Streaking | Thin, dark stripes | Contamination, high humidity, low load, low pressure | Clean, optimize load & environment, adjust brushes | If streaking comes with deep pitting or burning |

| Threading | Very fine “thread-like” lines | Brush dust, poor surface finish, vibration | Machine commutator, rebalance rotor, check bearings | If threads deepen into cracks or severe wear |

| Photographing | Dark tracks as wide as brush | Condensation under brushes, electrical spikes, shocks | Fix moisture source, surge protection, re-surface commutator | If bars are cracked, overheated, or loosened |

| Bar edge burning / slot marking | Alternate bars dark/burnt | Uneven current distribution, bad interpoles, winding faults | Investigate & fix electrical cause, recondition surface | Often accompanies internal armature faults – replacement of commutator and/or rewind |

| Copper drag | Smeared, rippled copper surface | Overheating, overloads, poor cooling | Reduce load, improve cooling, machine & undercut | If segments have softened, lifted, or distorted |

This table is your “don’t panic yet” tool: a lot of ugly-looking commutators can be repaired by machining, undercutting insulation, and correcting brush issues—before a full replacement is necessary.

3. Repair vs Replacement: A Simple Framework That Actually Works

Not every damaged commutator has to be replaced. In many cases, it’s more economical to recondition it (turn it on a lathe, undercut the mica, and rebalance the rotor). Industrial service centers routinely do this as long as the underlying copper and insulation are still structurally sound.

When deciding whether to repair or replace, think in three layers:

- Mechanical condition

- Is the commutator still round? (Runout within spec?)

- Is there enough diameter left after machining?

- Any lifted bars, cracked segments, or loose risers?

- Electrical condition

- Insulation between segments still intact?

- Any evidence of shorted bars or armature faults?

- Interpoles and field circuits healthy?

- Economic & strategic factors

- Age and criticality of the motor

- Downtime cost vs cost of new motor

- Availability of identical replacement motors

- Plans to upgrade to brushless or different drive technology

A reliable rule of thumb used by motor shops:

- If the commutator can be cleaned, lightly machined, and undercut while staying above minimum diameter and within runout tolerance—and the armature tests good—repair is usually preferred.

- If bars are loose, cracked, deeply burnt, or the diameter is already close to the limit, replacement is the safer long-term choice, especially on critical production equipment.

Questions to Ask Before Approving Commutator Replacement

- How many times has this commutator already been machined down?

- After machining, will it still meet the OEM minimum diameter spec?

- Are there any signs of lifted bars or looseness in the shell?

- Did surge / bar-to-bar tests on the armature show any winding faults?

- What’s the estimated remaining life of the motor after repair vs after full replacement?

- How does that compare to the cost of a new or modernized motor?

These questions turn the conversation with your repair shop from “Just fix it” into a strategic decision.

4. What Actually Happens During Professional Commutator Replacement

For anything beyond a small low-voltage hobby motor, commutator replacement is not a bench-top quick fix. It’s a precision operation with presses, lathes, and high-voltage test equipment, and it usually requires disassembling the motor and removing the rotor or shaft.

A typical professional commutator replacement process looks like this:

- 1. Incoming inspection & documentation

- Photos of lead connections, brush positions, and nameplate data

- Tests on windings (insulation resistance, surge tests, bar-to-bar)

- 2. Mechanical stripping

- Motor is fully disassembled; rotor removed

- Old commutator is pressed off the shaft or separated from the core

- 3. Shaft & hub preparation

- Shaft journals inspected and measured

- Any wear, scoring, or deformation corrected

- Keyways and fits verified so the new comm sits dead concentric

- 4. Installing the new commutator

- New comm (often custom-built for molded units) pressed onto shaft/hub with specific interference fit

- Risers or tangs aligned to match existing armature coil connections

- 5. Reconnecting armature windings

- Coils soldered or welded to commutator risers / tangs

- Joints cleaned and inspected to avoid dry joints and hot spots

- 6. Machining, undercutting & profiling

- Commutator turned on a lathe to final diameter and roundness

- Insulation between bars undercut to proper depth (often ~0.5–1 mm)

- Surface “stoned” or polished to achieve a brush-friendly finish

- 7. Balancing & final tests

- Rotor dynamically balanced to reduce vibration

- High-voltage tests repeated, plus functional run test with brushes in place

- 8. Reassembly & alignment

- Bearings, seals, and brush gear reinstalled or renewed

- Brush grade, spring pressure, and neutral plane set according to spec

What matters to you, the owner, is that:

- The mechanical fit is correct (no runout, no looseness)

- The electrical connections are solid and properly insulated

- The brush system is tuned for the new surface, not just “put back together”

If your repair quote simply says “commutator replaced” with no detail, that’s a hint to ask more questions.

5. Is Commutator Replacement Expensive? Yes, No, and “It Depends”

Short answer: it depends heavily on the motor size and application.

Industry articles aimed at large industrial users report that commutator replacement on big DC machines (heavy machinery, power generation, etc.) can run from roughly $2,000 to $10,000, depending on size, complexity, and local labor rates.

For smaller motors (automotive, small tools, fractional horsepower units), the part cost can be modest—but labor, balancing, and testing still add up.

Cost drivers you should be aware of:

- Type & size of motor

- Big industrial machines cost more in both parts and handling—cranes, special jigs, etc.

- Labor intensity

- Disassembly, press work, careful reconnection, machining, balancing, and test time are all labor-heavy.

- Additional repairs discovered

- If a failed commutator is just the symptom of armature winding faults, bearing damage, or core problems, those costs get added on.

- Downtime

- Sometimes, the biggest “cost” is lost production while the motor is out of service. It can easily dwarf the invoice from the repair shop.

When Replacement Is NOT Worth It

There are situations where replacing the commutator is a bad investment:

- The motor is cheap and easily replaceable as a whole unit

- Efficiency and performance are outdated, and production already wants to move to modern drives

- The rest of the motor (stator, frame, bearings) is at the end of its life

- You can replace the application with a brushless DC (BLDC) or AC drive that eliminates the mechanical commutator entirely

In those cases, it may be smarter to put the money into upgrading rather than resurrecting.

6. How to Avoid Needing Comm utator Replacement Again Anytime Soon

Here’s where you can really help your readers: show them how good habits dramatically extend commutator life.

Most authoritative repair guides agree that commutator failure is often the last step in a chain of smaller, preventable issues—brush mistakes, contamination, wrong duty cycle, etc.

Core maintenance practices:

- Use the right brush grade

- Different applications need different carbon/graphite mixes. The wrong grade can groove or burn the commutator quickly.

- Set spring pressure correctly

- Too low = arcing, streaking, and poor contact.

- Too high = rapid brush and commutator wear.

- Keep things clean

- Regularly blow out carbon dust (safely), wipe away oil and contamination, and check cooling paths.

- Avoid prolonged light-load operation

- Some DC motors at very low load can develop streaking and unstable film on the commutator.

- Watch ambient conditions

- High humidity, corrosive fumes, and conductive dust all attack the commutator film and insulation.

- Monitor brush wear and commutator visually

- Build a simple monthly inspection into your PM plan. Snap phone photos for trend comparison over time.

7. Should You Jump to Brushless and Forget Commutators Forever?

You’ll often hear: “Let’s just get a brushless motor and be done with all this commutator drama.”

Brushless DC (BLDC) motors replace the mechanical commutator and brushes with an electronic controller that switches currents in the stator windings instead. No sliding contacts, far less wear, and often higher efficiency—especially where precise speed control is important.

Upgrading from brushed DC to BLDC or AC drive can be a great move when:

- You’re redesigning an entire machine or line

- Precise control and high efficiency are priorities

- Maintenance access is difficult, making brush service a pain

- Lifecycle cost matters more than lowest first cost

But for many applications—existing cranes, mills, legacy DC drives, special torque-speed profiles—keeping the brushed DC motor and doing smart commutator work is still the most economical path.

Final Thoughts (You Can Adapt as Your Blog’s Conclusion)

Commutator replacement sounds like a niche technical topic, but for anyone who lives with DC motors, it’s directly tied to downtime, safety, and budget.