Electric Motor Commutator

The commutator in an electric motor is a rotary electrical switch mounted on the rotor (armature). It periodically reverses the current in the armature windings so that the electromagnetic torque continues to act in the same direction. In simple terms, the commutator in motor is what turns pulsating electrical input into smooth mechanical rotation.

Each commutator in a motor is made of copper segments (bars) insulated from each other by mica or high-temperature resin. Carbon brushes ride on these segments, feeding current into the armature winding. The commutator of motor therefore directly affects:

- Torque stability and startup performance

- Brush wear and commutation sparking

- Motor efficiency, heat and noise levels

Electric Motor Commutator Manufacturer in China

As a leading electric motor commutator manufacturer in China, XDC supplies high-precision, long-life commutators for DC motors, universal motors and automotive starter and traction motors. From miniature fan motors to high-current industrial drives, our motor commutator portfolio is engineered for stable torque, low sparking and reliable operation in demanding applications.

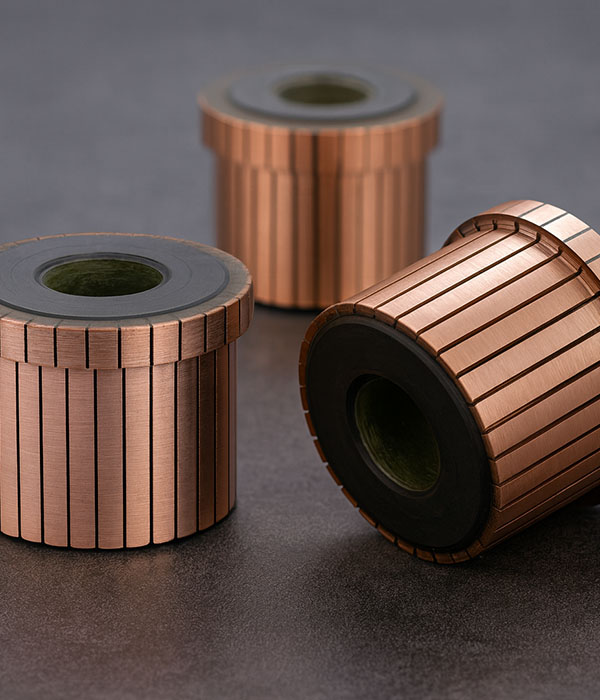

Electric Motor Commutator Manufactured by XDC

Experience the versatility of XDC’s Electric Motor Commutators. We excel at producing components strictly according to your provided diagrams. Our process ensures confidence by starting with test units before scaling up to bulk manufacturing. Check out the diversity of our past work here, and directly send us your drawings to get a quote.

Reinforced 10-Segment Commutator

Molded with high-stability thermoset resin, this 15mm unit ensures superior dielectric strength between its 10 bars. Engineered to maintain structural integrity under thermal stress and heavy loads.

3-Bar Fusing-Optimized Commutator

The right-angle tang geometry creates an ideal surface for electrode contact during the fusing process. This ensures consistent, low-resistance electrical joints, critical for maximizing motor efficiency.

14-Bar Stable-Contact Commutator

The 14-segment geometry significantly reduces the mechanical “polygonal effect” relative to the brushes. This ensures continuous, bounce-free contact and prevents physical wear caused by brush vibration.

High-Capacity 3-Bar Commutator

The 3-segment configuration on this 7.6mm unit maximizes the copper surface area per bar. This physical design supports higher current densities and robust thermal endurance for heavy-load motor applications.

Bi-Directional 5-Bar Commutator

The 5-segment geometry provides symmetrical switching properties, making it superior for reversible motor applications. This 7mm unit ensures consistent torque and speed control in both clockwise and counter-clockwise rotations.

High-Precision 5-Segment Micro Commutator

Engineered with exacting molding tolerances, this 5.6mm unit maintains consistent insulation width between the 5 bars. This precision prevents inter-segment shorting, ensuring long-term reliability in miniature motor applications.

Metal-Brush Optimized Micro Commutator

Designed specifically for micro motors utilizing metal-finger brushes. The ultra-smooth surface finish minimizes mechanical friction and contact noise, preserving the integrity of delicate brush systems.

EMI-Optimized 6-Slot Commutator

The 6-segment architecture inherently generates lower voltage spikes during switching compared to 3-slot designs. This physical characteristic aids significantly in reducing Electromagnetic Interference (EMI), facilitating easier EMC compliance for your motors.

Engineering Advantages of XDC Commutator Electric Motor Designs

XDC focuses on performance and reliability at the heart of the commutator electric motor interface:

High-conductivity copper segments

Reduced I²R losses and lower heat in the commutator of motor, improving overall efficiency and power density.

Precision machining and tight runout control

Accurate ID/OD and roundness keep vibration low, even at high rpm, preventing brush bounce and uneven wear.

Optimized surface finish

Carefully controlled commutator surface roughness minimizes arcing and extends both commutator and brush life.

Thermal and mechanical robustness

Advanced resin systems and mica insulation allow the commutator in motor to withstand high temperatures and rapid thermal cycling.

Consistent commutation performance

Proper segment geometry and layout are tuned to your armature winding, neutral plane and interpole design, ensuring smooth torque and reduced electromagnetic noise.

Custom Sizes and Segment Ranges

Across all families, XDC can tailor motor commutator designs to your drawing:

- OD range: approx. 2.5 mm to 150 mm

- Segment count: from about 8 bars to 96

- Materials: pure copper or silver-copper alloys, mica or engineered polymer insulation

- Motor types: brushed DC motor, universal motor, traction motor, starter motor, generator

If you need a specific commutator in an electric motor design for a new platform, our engineering team can co-develop a prototype based on your armature winding and performance requirements.

Why Choose XDC as Your Electric Motor Commutator Partner?

As a dedicated Chinese manufacturer of motor commutator products, XDC offers a complete value package:

Focused Expertise

We specialize in the commutator in an electric motor field – not as a side product. Our engineers understand armature windings, interpoles, carbon brush grades and how each element affects commutation.

Wide Product Portfolio

From an 8-segment micro motor armature commutator for fans to multi-segment traction designs, XDC can support your entire motor line, simplifying your supply chain.

Customization and Co-Design

Share your shaft size, armature drawing and electrical requirements, and our team will tailor the commutator of a motor that meets your torque, speed and life targets.

Competitive Cost

Our location in China lets us combine advanced manufacturing with cost-effective production, giving you a reliable electric motor commutator source with strong price-performance.

Typical Applications for the Commutator of a Motor

XDC electric motor commutator products are running in millions of machines worldwide:

Household appliances

vacuum cleaners, mixers, blenders, fans

Power tools

drills, grinders, saws, sanders

Automotive systems

starter motors, wiper motors, window lifts, fuel and oil pumps

Industrial equipment

DC drives, small traction motors, pumps and blowers

Consumer products

toys, fitness devices, small personal care appliances

Contact XDC – Talk to Our Motor Commutator Experts

Looking for a new commutator in motor design or a second source for an existing motor line?

- Send us your motor armature commutator drawing (PDF/CAD) and expected annual volume.

- Our sales and engineering team will respond with a proposal covering design, tooling, samples and lead times.

Partner with XDC, and ensure the commutator of motor in your product is as reliable as the rest of your design.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Understanding the Role of Commutator in Electric Motor

The role of commutator in electric motor is to reverse the direction of current in the armature winding at precisely the right moment. This keeps the electromagnetic torque acting in a constant direction so the rotor continues to spin smoothly. Without a properly designed commutator in an electric motor, you would get poor starting, strong vibration and heavy sparking at the brushes.

A commutator in a motor is segmented; each copper bar connects to a different armature coil and is used to switch DC current direction. Slip rings are continuous rings, typically used in AC machines, to transfer power or signals without commutation. If your application needs a commutator electric motor (brushed DC or universal motor), slip rings cannot simply replace the commutator of a motor.

You should consider replacing the motor armature commutator when:

- Segments are heavily burned, cracked or loose

- The surface is deeply grooved beyond what turning can correct

- Mica insulation is damaged or lifting

- There are repeated shorts between segments

In these cases, fitting a new electric motor commutator from XDC will often restore performance and extend motor life more cost-effectively than repeated repairs.

To select the correct commutator of motor, you should confirm:

- Shaft diameter (commutator ID) and required OD and height

- Number of segments and connection type (hook, groove, slot)

- Motor voltage, speed and current

- Application duty cycle (intermittent, continuous, traction, starter)

Share this information with XDC and we will recommend or design the best motor commutator structure and materials for your project.

Yes. The geometry, surface finish and material of the commutator in an electric motor have a direct impact on brush life, sparking and electrical noise. A well-designed commutator in motor from XDC, matched with the correct carbon brush grade, can dramatically reduce maintenance and improve user experience.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…