Commutator in DC Motor Manufacturer in China

XDC is a leading commutator manufacturer in China, specialising in the commutator in dc motor assemblies used in power tools, appliances, automotive and traction drives. A commutator in dc motor converts the fixed DC supply into a reversing current in each armature coil, so that the motor produces smooth, continuous torque. Choosing the right dc motor commutator is critical for performance, efficiency and brush life in every commutator dc motor application.

Product Overview – From Mini Motors to Transmissions

Our commutator for dc motor range covers the typical industry envelope:

- Outer diameters from about 2.5 mm up to around 150 mm

- Standard and customised bar counts from 7 to 96 segments

- Hook, slot, riser and shell types to suit different armature winding methods

- Options for universal motors (AC/DC) and pure dc electric motor commutator designs

Whether you need a miniature commutator of dc motor for a seat actuator or a high-segment traction collector, XDC provides a complete commutator in dc solution.

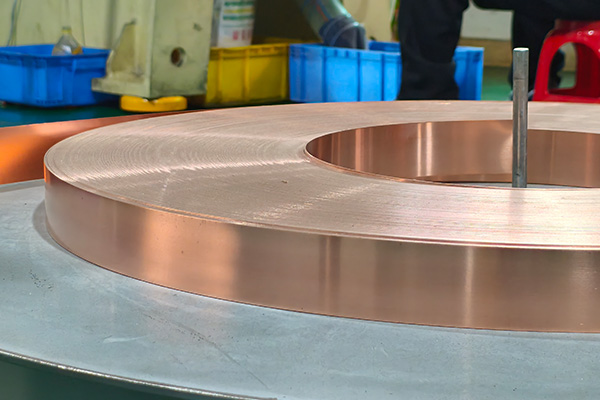

Commutator in DC Motor Manufactured by XDC

Explore XDC’s dedicated showcase of commutators for DC motors. We specialize in translating your engineering drawings into reality, supporting your project from initial sample verification to high-volume mass production. Whether for automotive or industrial DC applications, our quality matches your specifications. View our portfolio below and directly send us your drawings to get a quote.

3-Bar Hook Type Commutator

Equipped with robust bent hooks, this 3-segment unit ensures secure wire retention and reliable welding. Optimized for high-efficiency assembly in micro DC motor manufacturing.

11.4mm 14-Bar Hook Commutator

Featuring 14 precision-cut segments and an 11.4mm OD, this commutator is optimized for smooth rotation and reduced electrical noise, ensuring extended operational life for professional motors.

Micro 3-Segment Commutator

Engineered for miniature applications, this 3-bar unit features a 2.9mm OD. Its high-precision insulation ensures reliable commutation in compact motor designs, offering a ready-to-use solution for your needs.

Right-Angle 3-Slot Commutator

The distinctive right-angle tang design on this 3-bar unit facilitates superior winding securement. Engineered for motors requiring robust electrical connections and resistance to mechanical stress.

6-Segment Commutator

The 6-bar configuration on this 6.5mm unit significantly reduces commutation sparking and torque ripple compared to 3-slot standard models. Ideal for precision motors requiring smooth, quiet operation.

5.6mm 5-Bar Commutator

Engineered with a 5.6mm OD, this 5-segment design minimizes torque ripple and ensures reliable motor startup compared to 3-slot equivalents. Ideal for micro actuators requiring consistent output.

15mm 10-Bar Commutator

The 10-segment architecture effectively distributes voltage drop, reducing brush arcing and electromagnetic interference (EMI). With a 15mm OD, it supports stable current transmission for demanding industrial motor specifications.

Heavy-Duty 20mm 10-Bar Commutator

With a substantial 20mm OD, this 10-segment unit offers increased surface area for superior heat dissipation and high current capacity. Optimized for thermal management in powerful DC motors.

Why Choose XDC

1. Deep Engineering Experience

Our team understands the commutator in dc motor function in real machines – armature reaction, neutral plane, brush shifting and sparking control. We collaborate with your engineers on dc motor commutator design so that coil grouping, segment count and brush layout work together for sparkless commutation.

2. Customisation Without Complexity

Provide us with drawings, samples or basic parameters (OD, ID, height, bar count, type), and we recommend or develop the right commutator for dc motor configuration. From miniature 7-bar units to large traction collectors, XDC adapts geometry, materials and insulation to your application.

3. Stable Quality & Traceability

Each commutator in dc motor we produce follows controlled processes for copper forming, molding, machining and balancing. Batch records and process checks support long-term consistency, so your commutator dc motor platforms remain stable across production years.

4. One-Stop Supply for OEMs

Because our portfolio spans hook, slot, riser and shell types, XDC can act as your single source for dc motor commutator components across different product families: tools, appliances, automotive and industrial drives.

Materials & Construction

Each dc electric motor commutator is engineered for conductivity, mechanical strength and stable commutation:

- High-conductivity copper segments, with optional silver-bearing copper grades for demanding current densities

- Mica or engineered insulation between bars for high dielectric strength and thermal stability

- Molded bases using bakelite powder or engineering plastics with reinforcement rings and ceramic beads to keep segments locked at speed

- Precise hook or slot geometry for secure connections to armature winding in lap or wave patterns

This construction ensures that every commutator for dc motor integrates cleanly with armature cores, carbon brushes and brush holders.

Electrical & Mechanical Performance

To support robust commutator dc motor applications, our designs can be engineered and tested to:

- Withstand typical bar-to-bar and bar-to-ground test voltages in the hundreds to thousands of volts

- Maintain insulation resistance in the tens of megaohms range under test conditions

- Pass overspeed and thermal tests at high rpm and elevated temperatures, with minimal radial growth and run-out

Combined with correct brush grade and spring pressure, this yields a dc motor commutator that runs with low sparking, low noise and long brush life.

Quality, Inspection & Testing

XDC places strong emphasis on dc motor commutator inspection and dc motor commutator testing to ensure reliability in the field:

Dimensional checks

OD, ID, total and copper height, concentricity, run-out and bar alignment

Insulation tests

Bar-to-bar and bar-to-ground withstand voltage, insulation resistance across the commutator body

Mechanical testing

Overspeed tests at elevated temperature to verify that the commutator in dc motor remains stable under worst-case conditions

Visual and surface inspection

Verifying copper surface finish, undercut quality and absence of cracks or voids

Typical Application Scenarios

XDC supports a wide variety of commutator of dc motor applications:

Automotive

starter motors, seat and window actuators, water pumps, and auxiliary drives.

Smart Home

automated curtains, smart locks, robotic vacuum cleaners, and home automation actuators.

Power Tools

drills, grinders, saws, sanders, and polishers using universal motors with hook-type commutators.

Robotics

servo motors for joints, drones, and precision drives for service robots.

Transmission Industry

high-durability commutators for gearmotors, industrial actuators, and drive systems.

Contact Us Now

Looking for a reliable partner for your next commutator in dc motor platform or a customised commutator for dc motor series?

XDC – China Commutator Manufacturer Share your drawings, samples or basic parameters (OD, ID, height, bar count, motor type), and our team will recommend the optimal commutator dc motor solution for your application.

Contact us today to discuss your project and receive a tailored quotation for your dc electric motor commutator requirements.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Technical Questions Our Customers Ask

The function of a commutator in a dc motor is to reverse the current direction in each armature coil as the rotor turns, so the electromagnetic torque always acts in the same rotational direction. In simple terms, the commutator in dc motor converts the fixed DC supply into a sequence of switched currents that keep the rotor turning smoothly.

The commutator function in dc motor performance directly affects efficiency, brush life and noise. A well-designed commutator in dc motor with the right bar count and brush geometry reduces sparking, limits temperature rise and delivers consistent torque over the full speed range.

The commutator in dc motor function depends on the copper segments, the carbon brushes and the armature winding working in sync. Brushes press on the segments, feeding DC current into selected armature coils; as the rotor turns, the commutator switches the connections so the magnetic field and torque stay aligned.

The purpose of commutator in dc motor tools and appliances is to provide high starting torque, adjustable speed and compact size. By using a properly engineered commutator on dc motor universal motors, devices like drills, grinders, blenders and vacuums deliver strong performance from a relatively small package.

The use of commutator in dc motor traction and starter systems is to handle very high starting currents and repeated start–stop cycles. High-segment commutator of dc motor traction units and starter collectors must manage both electrical and mechanical stress while maintaining reliable switching between bars.

Our engineers work with you on dc motor commutator design from the concept stage. We help define bar count, commutator diameter, hook or riser type, insulation system and brush arrangement so your dc electric motor commutator meets torque, speed, lifetime and cost targets.

XDC’s dc motor commutator inspection includes dimensional measurement, bar alignment checks, surface finish evaluation and verification of the insulation system. We ensure every dc motor commutator meets drawing specifications before moving to final testing and packing.

Our dc motor commutator testing covers electrical withstand tests, insulation resistance measurement and, where required, overspeed and thermal testing. This confirms that each commutator in dc application can operate safely under its specified voltage, current and speed conditions.

Latest from Blog

Our blog content will provide you with a wealth of information and inspiration. They not only reflect our expertise and experience, but also encourage you to explore and discuss relevant topics with us.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…