Commutator in DC Machines

DC machine commutator is a rotary electrical switch mounted on the armature. It consists of copper segments (bars) separated by mica insulation, with carbon brushes riding on the commutator surface. In a commutator in DC machines design, these segments reverse current in the armature winding at exactly the right instant so that the torque in a commutator in dc motor remains unidirectional, and the output of a commutator in dc generator becomes smooth DC instead of raw AC.

Commutator in DC Machines Manufacturer in China

At XDC, China’s premier commutator manufacturer, we design and build every DC machine commutator to keep your motors and generators running efficiently, quietly and reliably. When OEMs, maintenance teams and rewind shops search for a commutator in DC machines, they need hardened engineering, not generic catalog parts. Whether you call it a commutator DC unit, a motor commutator or a generator commutator, XDC delivers industrial-grade performance tailored to your application.

Commutators in DC Machines Manufactured by XDC

Explore XDC’s specialized portfolio of commutators for DC machines. We focus on manufacturing high-precision components based on your unique designs, seamlessly guiding projects from initial sampling to full mass production. Whether for industrial or automotive DC motors, we ensure exact compliance. Review our specific cases below, and directly send us your drawings to get a quote

Custom Hook Commutators

Precision 14-segment hook commutator featuring 11.4mm OD. Expertly customized for motor applications. Existing molds are available to save tooling costs for this specific dimension.

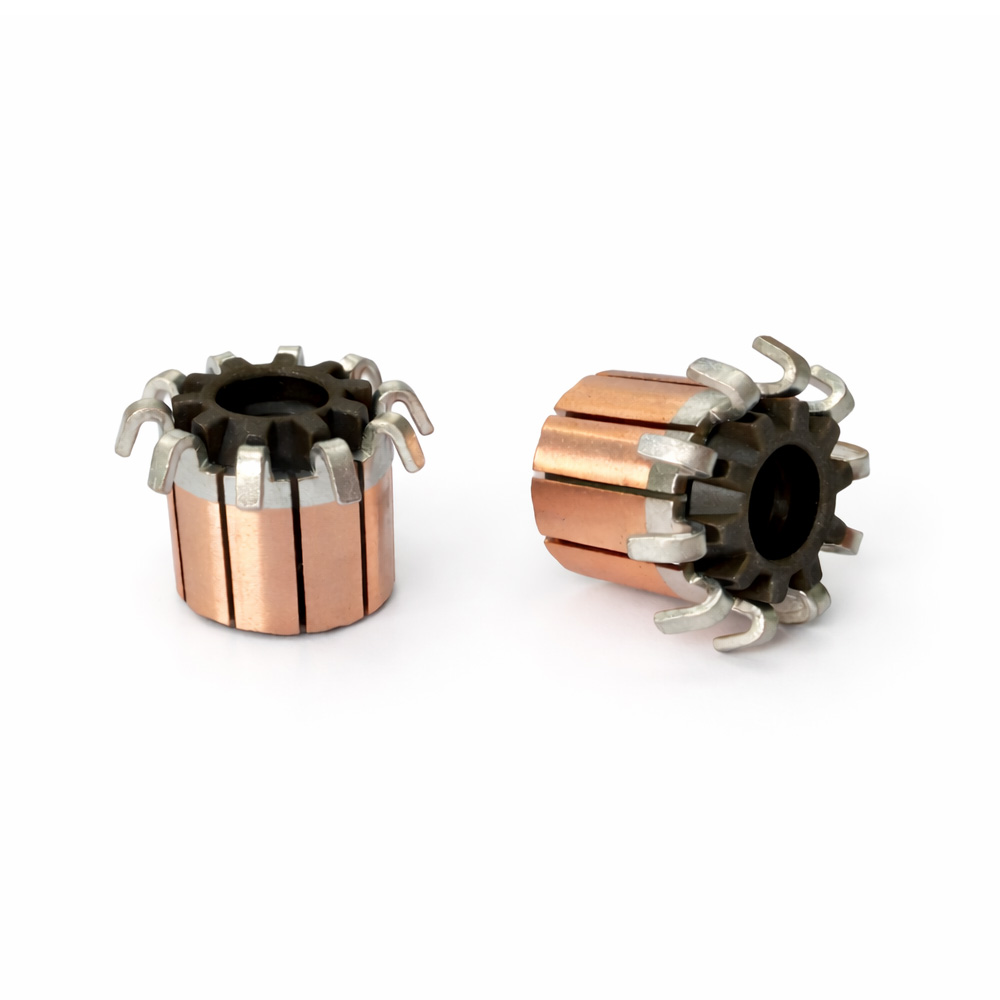

10-Segment Hook Type Commutator

Engineered with a 15.2mm OD and 10 segments, this hook-type unit ensures superior conductivity and structural integrity. Ideal for high-performance DC motor manufacturing and custom assembly.

3-Segment Right-Angle Commutator

Featuring a specialized 3-bar configuration with right-angle tangs for secure wire bonding. Designed for high-speed micro motors requiring compact dimensions and reliable electrical transmission.

7.6mm 3-Segment Hook Commutator

Designed with a 7.6mm OD and 3 segments, this component provides excellent high-speed stability. It ensures efficient current commutation and is compatible with various micro DC motor assemblies.

15mm 10-Segment Hook Commutator

Precision-engineered with a 15mm OD, this 10-slot unit offers exceptional dimensional stability. It is designed to handle high rotational speeds while ensuring minimal sparking and extended motor life.

Miniature 2.9mm Hook Commutator

Featuring an ultra-compact 2.9mm OD, this 3-segment component is precision-crafted for micro and coreless motors. It delivers stable performance in the smallest electromechanical applications.

6-Slot Compact Hook Commutator

Featuring a 6.5mm OD and 6-segment design, this component offers excellent rotational balance and thermal stability. Built to ensure consistent contact and longevity in diverse DC motor applications.

7mm 5-Slot Hook Commutator

With a standard 7mm OD and 5-bar configuration, this commutator delivers a perfect balance of torque and speed. Constructed for high mechanical endurance in demanding motor environments.

DC Machine Commutator Details

XDC manufactures commutator in DC machines solutions across a very wide dimensional range, from compact power-tool units to large industrial and traction sizes.

Dimensional specs we work with

For every commutator DC model we define and control:

• OD, ID and total height

• Copper/segment height

• Bar number and bar pitch

• Type: hook, riser, shell or slot-type commutator

Provide us with your old commutator in DC machines sample or drawing (OD, bore, length, segment count) and XDC will design a precise equivalent or upgrade.

Copper alloy & silver content

We use high-conductivity copper bars, often with 0.03–0.08% silver content, to stabilize resistance and mechanical strength at elevated temperature. That means your commutator DC unit handles surge currents and overloads without softening or deforming.

Insulation and mechanical base

Each DC machine commutator uses:

• Mica insulation between copper segments

• High-strength plastic or molded base for slot-type designs

• Solid hub/bush construction to lock segments in place

This construction is ideal for high-speed commutator in dc motor designs in power tools, universal motors and compact industrial drives where overspeed and vibration are unavoidable.

Thermal performance & duty life

During manufacture, each DC machine commutator assembly is baked at high temperature (around 200–232 °C depending on design) to stabilize copper, mica and resin systems. For continuous-duty cranes, hoists, rolling mills or DC generators in harsh process environments, an XDC commutator DC unit provides the thermal headroom your machine needs.

Usage scenarios & applications

XDC supplies commutator in DC machines solutions for:

- Light & medium-duty: power tools, household appliances, window lift motors, small starter motors, universal motor drives

- Heavy industrial: mining motors, industrial DC motors, DC generators on test benches, rolling mills, cranes and hoists

- Traction & automotive: traction motors, truck DC motors, electric flatbed trucks and starter-generator systems

In every case, the DC machine commutator is dimensioned for your shaft diameter, keyway, OD and stack length, and matched to the armature winding and load profile.

Why Choose Us – XDC Advantage

At XDC, we don’t just sell a commutator in DC machines and walk away. We build parts that make your life easier on the shop floor. If your project depends on a reliable DC machine commutator, XDC is the team you call when you want it done right the first time.

We’ve probably already made what you need

Various commutator DC designs in our library. Send us your size and segment count, and we’ll match or tweak it fast.

Machining that keeps brushes happy

We keep run-out tight and the surface smooth, so brushes sit well, spark less and last longer.

Good materials, no shortcuts

High-purity copper (with 0.03% - 0.08% silver content), solid mica insulation and resin that can handle heat and high speed. Your DC machine commutator is built to work, not just look good.

Stable quality and clear delivery

Every batch of commutator DC products is tested and recorded. You know what you’re getting, and when you’re getting it.

Contact Us

Ready to upgrade or replace your commutator in DC machines?

XDC – China’s Premier Commutator Manufacturer

- Send us your drawing

- Please let us know any additional requirements you have for the commutator

- Receive a clear technical proposal, price and lead time for the right commutator DC solution

Reach out via email or phone, or upload your specifications through our online form. XDC is ready to support your motors, generators and universal machines with industrial-grade commutators that keep your DC drives running at their best.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

XDC Commutator - FAQ

The commutator function in DC machine operation is to:

- Reverse the current in each armature coil as it passes the magnetic neutral axis

- Maintain unidirectional torque in a commutator DC motor

- Rectify the internally induced alternating EMF into a usable DC output in a generator

In practice, this means a properly engineered commutator in DC machines gives you stable torque, lower sparking, longer brush life and cleaner DC for your load. At XDC we tune segment geometry, surface finish and copper grade so your DC machine commutator supports sparkless commutation even at high load and high speed.

To define commutation in DC machine engineering terms: commutation is the brief period during which the current in an armature coil is forced to reverse while it is short-circuited by a brush bridging two commutator segments. Poor commutation causes arcing, brush wear and burnt commutator bars; good commutation gives quiet operation and long life.

Our DC machine commutator design supports clean commutation using:

- Optimized bar shape and segment pitch

- Precise alignment with the magnetic neutral axis

- Compatibility with commutating pole (interpole) systems and compensating windings

For new projects or replacement commutator DC assemblies, XDC designs around your magnetic circuit to keep commutation under control.

Yes. Send us basic data for your DC machine commutator—OD, ID (bore), total length, number of segments, photos, and (if possible) the old drawing or sample. Our engineers will reverse-engineer the design and propose a fully compatible replacement or an upgraded commutator DC unit.

Typically, our MOQ is 100 units. Tooling lead time is 40–45 days, and production lead time is 15 days (depending on order volume).

For common DC machine commutator sizes from our existing library, lead times are usually shorter and minimum order quantities are flexible for OEMs and MROs. Custom commutator DC designs may require additional engineering and tooling time. After we review your specs, we’ll confirm a realistic lead time and MOQ together with the technical proposal.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…