What is commutator film and why is it important?

Commutator film is the ultra-thin, copper-oxide–rich layer that sits between your brushes and the copper bars. When it is stable, your DC machine runs quietly, wears predictably, and keeps its commutation under control. When it is not, everything else you do is mostly damage control.

Table of Contents

A definition that actually matches what you see in the field

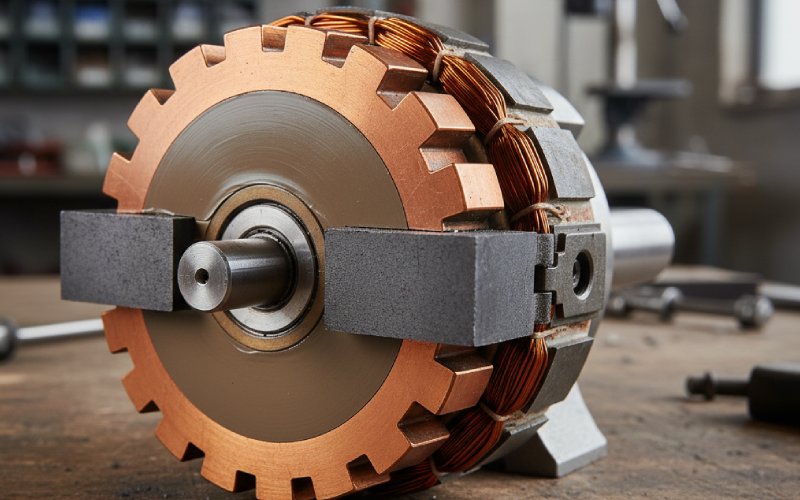

The documentation usually calls it an “oxide film” on the commutator. Strictly speaking, that is only the core of it. In practice, the film is a tribolayer: mostly copper oxides, plus graphite from the brushes, plus absorbed water and trace contaminants such as sulfates and chlorides from the air.

Under a carbon brush, that mix is constantly being created, compacted, sheared and re-formed. You never get a static coating. You get a moving equilibrium that lives in the top few micrometres of the surface. An accepted rule of thumb is that a commutator turned to a roughness around 35–60 microinch helps this layer form properly; if you polish the copper too smooth, the film struggles and the brush just skates and erases what little film is trying to grow.

Without this film, a carbon brush would wear almost like chalk on a slate. That is not exaggeration; it shows up directly in classic test data from brush manufacturers.

Why such a thin layer ends up running the show

You already know the copper, the windings, the core steel. They are big decisions. Still, during day-to-day operation of a DC motor or generator, the commutator film quietly dictates several things at once. It sets the effective contact resistance between brush and bar. It controls friction levels. It affects local temperature near the brush face. It shapes how current transfers from segment to segment at the instant of commutation and whether you see sparking or a clean transfer.

Because all of these depend on a layer only a few microns thick, the machine can look mechanically solid and electrically correct on paper yet behave badly in the real world if the film is wrong for the duty and environment. That is why experienced maintenance people sometimes talk more about “getting the film right” than about anything else on the rotating side.

A more awkward truth: you never fully control the film. You only influence it. Brush grade, commutator surface, atmosphere, loading pattern. Those four levers, pulled together, nudge the layer toward a stable state that suits your machine. Or push it into a pattern of constant change and complaints.

What a healthy commutator film really looks like

Most practical guides end up here: “thin, uniform, brown/grey patina”. That is the standard description, and it is not wrong. It is just incomplete. In reality you read film quality from a combination of color, texture, and pattern across the full circumference.

Here is a compact view you can map to what you see during inspections:

| Film appearance | Likely condition | Typical underlying situation | Suggested mindset / action |

|---|---|---|---|

| Light, even brown-grey, slightly satin, no streaks | Stable film, good brush contact, normal commutation | Surface roughness in a reasonable band; brush grade matched to duty; environment not too dry or corrosive | Treat as the reference state. Record photos. Do not “improve” it with unnecessary polishing. |

| Slightly darker chocolate tone, still uniform and smooth | Often acceptable on high-load, lower-voltage machines; film carrying more graphite | Higher current density, brush grade on the softer or more graphitic side | Keep an eye on temperature and wear; if stable over time, leave it alone. |

| Very dark or black, patchy or sooty, sometimes with matte islands | Film contaminated; risk of selective brush action and sparking | Sulfur-bearing atmosphere, high humidity, other reactive gases, sometimes inadequate ventilation | Investigate the environment first, not just the commutator. Cleaning and a more abrasive brush grade can be justified if the source cannot be removed. |

| Bright metallic copper with almost no visible patina | Film stripped or never formed; brushes running directly on copper | Over-aggressive cleaning, brand new commutator with inappropriate surface finish, or frequent stop–start duty that prevents film stabilization | Allow controlled run-in with correct loading and brush grade. Avoid solvent cleaning during this phase. |

| Discrete darker bands under some brush paths, lighter under others | Unequal current sharing; local film break or uneven brush pressure | Variations in spring pressure, brush grade mixing, or film damaged in some tracks | Measure voltage drop per brush arm; correct pressure and alignment; avoid mixing brush grades on one polarity. |

| Streaks, radial scratches, ridges, or copper drag | Mechanical distress of the surface; film cannot stabilize | Brush chatter, incorrect spring pressure, commutator out-of-round, or abrasive particles embedded in brushes | Address the mechanical source. Do not expect a new film to mask significant runout or vibration. |

This table is deliberately short on small variations. In practice, you will see blends of these states. That is normal. Machines rarely live in textbook conditions for long.

How the film forms, step by step (even though it never really stops)

When you start a machine with new or freshly turned copper, contact between brush and bar is mostly metal-to-carbon. Each pass of the bar under the brush generates local heating and micro-arcing. Copper on the peaks oxidizes, some of it transfers into the brush face, some of it compacts back into the commutator surface. In parallel, graphite from the brush smears and reacts at the same interface, and water from the air adsorbs into this porous layer.

After enough revolutions under stable conditions, those three ingredients settle into a relatively consistent layer. Not fixed, but self-maintaining. The brush constantly removes a little material while the electrical and mechanical contact constantly rebuilds it. That dynamic balance is what you actually want.

If you change any of the surrounding conditions abruptly, that balance can shift in a few minutes. A different brush grade, a big change in loading, a move to a much drier or more humid atmosphere or a resurfacing of the commutator can all reset the film process almost back to the beginning. The machine may then behave as though it just left the factory, even if the windings are decades old.

Why the environment matters more than the datasheet suggests

Manufacturers repeatedly note that commutator film is extremely sensitive to atmosphere, especially moisture level. In dry air the film tends to become too resistive and can fragment; in damp or contaminated air it can go soft, streaky or conductive in patches. You see this as a shift in sparking behavior, brush wear pattern, and even audible noise long before you see dramatic electrical failures.

Industrial sites with sulfur-bearing fumes, or coastal plants with salt-laden air, often end up with darker, sometimes nearly black films. These carry reaction products that do not give you the controlled, slightly semiconducting interface you rely on. They also drive “selective action”, where a subset of brushes carries disproportionate current and wears faster than others.

The practical conclusion is simple but easy to miss. You are not just maintaining copper and brushes; you are managing a chemical surface system that is open to the room air. Ventilation, filters, and even where the machine sits in a building are part of film control, whether the drawings show it or not.

Brush grade and film: a two-way negotiation

The usual story is that brush grade affects film. That is true. Softer, more graphitic grades tend to build film faster and darker. Harder grades with more metallic content tend to clean the surface and leave a thinner, lighter film.

But the reverse is also real: the film you already have affects how a given brush behaves. A brush that performs well on one machine can act abrasive on another because the existing film is different. In that sense, selecting a brush grade is always a negotiation with the film that is already there.

This is why many manufacturers recommend removing the old film from the brush tracks when changing to a significantly different brush grade. The goal is to avoid running a new grade on top of a film tuned for another material and operating pattern.

You end up with a workflow like this, whether written down or not: assess the existing film, decide whether to keep or reset it, choose brush grade and spring pressure accordingly, then give the system enough running time under realistic load to settle. If you change several variables at once, the film usually tells you, and not kindly.

Cleaning, resurfacing, and the temptation to overdo it

Most plants tend to over-clean commutators. Solvent wipe, abrasive paper, sometimes aggressive stone work. It feels like good practice because the copper looks bright afterwards. Unfortunately, that “like new” shine means you just removed the functional part of the interface.

Technical notes from both OEMs and repair shops warn against using common abrasives such as aluminum-oxide emery cloth on commutators, because conductive particles can embed in the film and cause arcing. They recommend garnet paper, proper stones, or specially designed cleaning brushes when in-place cleaning is unavoidable.

The subtle part is deciding when cleaning is truly unavoidable. Dark but uniform film with acceptable brush wear often does not need to be removed. Black, patchy film that correlates with visible sparking, selective brush loading, or local heating almost always does. You match the decision to the pattern, not only to the color.

Reading problems through film patterns

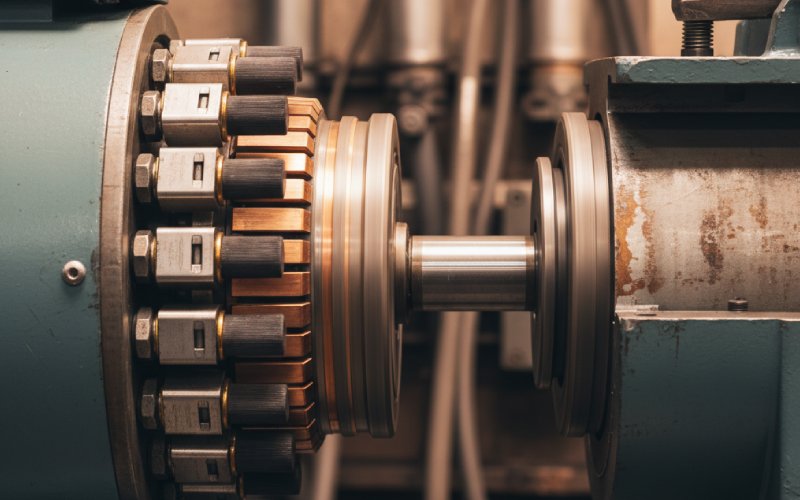

If you walk up to a motor and the film looks uneven, you can usually narrow your diagnosis to just a few causes before touching a tool. Uneven banding along the circumference often traces back to non-uniform brush pressure or slight eccentricity in the commutator. Localized bright areas in otherwise well-filmed surfaces often point to a specific brush that is chattering or running with too low pressure, wiping the film away in its path.

When film breaks in one track of a multi-brush arm, that brush path can end up with a higher voltage drop, carrying more current and heating more. That in turn stops the film from re-establishing, which gives you a self-reinforcing hot spot. Several maintenance guides describe this exact loop and suggest checking voltage drop per brush arm to catch it early.

The nice part is that once you start treating film appearance as a live indicator, not just a cosmetic detail, you get earlier warning of commutation problems than you do from insulation resistance tests or vibration alone.

How to improve the film without chasing it every week

If you want the film to be stable, the machine has to be allowed to live in a relatively stable world. That sounds obvious but is easy to forget in real operation. Frequent start–stop cycling, large swings in load, rapid environment changes, constant grade changes on brushes: all of these keep the interface in a permanent “running in” state. That usually shows up as inconsistent color, variable wear between brushes, and a need for frequent cleaning or resurfacing.

A more sustainable approach is usually quieter: pick a brush grade that is appropriate for your voltage, current density, and duty cycle; confirm commutator geometry and roughness are within the ranges that your brush supplier recommends; verify that cooling and filtration keep the atmosphere around the commutator reasonably stable; then let the machine put operating hours on itself without constant interference.

You will still intervene, of course. But the interventions become slower and more deliberate. You change one thing at a time, then watch what the film does over days, not minutes. That is closer to how the interface actually behaves.

When is film no longer the problem?

One last point that often gets lost in film-centric discussions. Sometimes the film is only reflecting a deeper issue. Significant mechanical runout. Loose windings. Poor commutation design margin for the load dynamics. In those cases, you can spend months changing brush grades and cleaning routines and never get to a stable film because the root cause makes the interface unstable by design.

A rough rule: if the film keeps reverting to a damaged or uneven state in the same spots despite careful, single-variable changes, start checking the underlying geometry and electrical design again. Slot bar burning, recurring ridges, and repeated film loss at identical angular positions usually belong to that deeper category.

At that point, treating the film as “the problem” is like blaming the thermometer for the temperature. The film is just showing you what the system is doing.

Closing thoughts

Commutator film is not a cosmetic layer or a minor detail from the brush catalog. It is a live, microns-thin interface that sits exactly where your machine transfers current between rotating and stationary parts. It is made from copper, carbon, water and whatever the local air provides. It records how you actually operate the motor, not just how it was specified.

If you treat that film as something to understand and influence – rather than polish away – you get longer brush life, cleaner commutation, and fewer surprises after start-up. It is a small thing on the drawing that turns out to be a large thing in practice, and your inspections should match that reality.