Commutator Cleaning Stick: Small Tool, Big Effect On Brush Life

Used properly, a commutator cleaning stick simply refreshes the copper, keeps the graphite film honest, and gives new brushes a clean, dimensionally safe surface to work with. That’s it. If you ask it to fix deeper electrical or mechanical faults, it will quietly disappoint you.

Table of Contents

What a commutator cleaning stick is really for

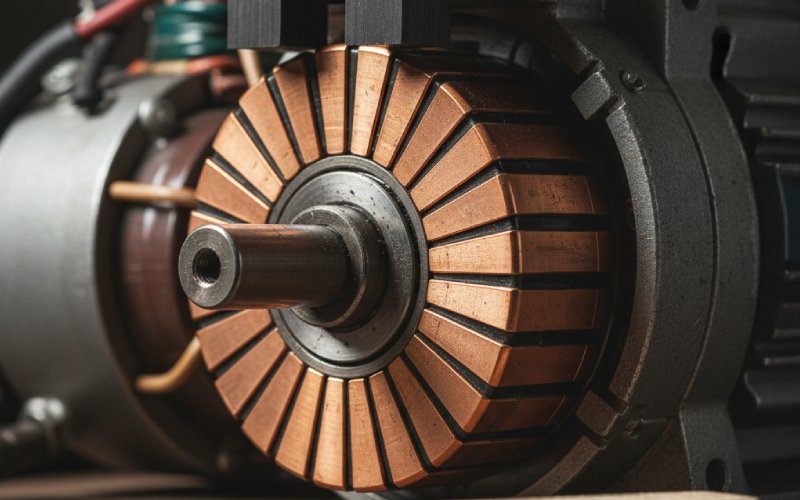

Manufacturers describe these sticks as very fine, non-contaminating abrasives designed to “refresh” the commutator surface just before or after carbon brush work. They’re meant to remove light carbon build-up and minor spotting without cutting the bars down or changing the mechanical properties of the surface.

In other words, this is a finishing and housekeeping tool, not a rescue tool. It shines when: the bars are still round, the mica is already undercut correctly, and the machine only shows light streaking or contamination. On that kind of commutator, a short session with the stick can noticeably extend the life of the next brush set by improving contact and reducing localized hot spots.

If the surface is badly grooved, bars are loose, or you’re seeing bar edge burning, copper drag, or signature slot-bar marking, the stick is the wrong tool. Those patterns normally point to brush alignment, spring pressure, or winding issues that require machining, brushgear adjustment, or outright repair, not cosmetics.

Read the commutator before you touch it

A lot of commutators get “cleaned” that should have been left alone. Experienced techs read the film first.

Carbon brush and motor manufacturers consistently point to a uniform light-to-medium brown film as the ideal state for good brush and commutator life.That thin layer of copper oxides and graphite acts as a dry lubricant and stabilizes contact resistance. When it’s even, the machine is usually happy. Removing it just because the copper doesn’t look pretty is a step backwards.

Technical guides go so far as to say that if the machine is performing well and the commutator isn’t wearing progressively, you should leave it alone, even if the surface looks a bit patchy or not “copy-book smooth.” The cleaning stick is for when that film is contaminated, uneven, or about to meet a fresh set of brushes that deserve a fair chance.

So the first question isn’t “Which grit?” but “Does this actually need to be touched?”

How to use a commutator cleaning stick without ruining the film

You already know the lock-out, tag-out routine and how to expose the commutator safely, so this skips straight to what usually gets glossed over: how the stick actually meets the copper.

On small motors used in hobby or light industrial work, a common sequence is to wash the commutator with motor spray or contact cleaner, let it dry, then apply the stick while turning the shaft. RC guides describe exactly this: spray from several angles, dry, then hold the square end of the stick gently on the commutator while rotating the shaft, often followed by a finer “polishing” stick. That basic geometry works almost everywhere.

For industrial sticks like the ones sold into DC machine maintenance, the manufacturer’s own instructions say the same thing in different words: present the stick in the direction of rotation, use moderate pressure, and sweep left and right across the track while the commutator turns. Think of it as hand-dressing, not grinding. You’re trying to wipe off high-resistance spots and compact minor surface roughness, not flatten the world.

A few details matter more than people admit:

You want the lightest pressure that still produces a consistent matt finish on the track. Leaning in harder just makes heat, risks softening the copper surface, and encourages copper drag, where metal smears across the slots.

You want motion. Holding the stick in one place while the rotor spins under it will carve a localized band and disturb the film pattern. Walking the stick gently around the circumference or across the track spreads the work and keeps the film more even.

You really want to clean afterward. Technical guides on commutator and brush seating insist on blowing or vacuuming out every trace of abrasive and copper debris once the operation is done, especially from the mica gaps. A cleaning stick is less aggressive than a grinding stone, but the dust is still abrasive, and you don’t want it packed into the slots.

If you’re tempted to mount the stick in a power tool to “speed things up”, pause. Sticks are formulated to be gentle when used by hand or against a normally running rotor. Adding a high-speed spindle changes the whole thermal picture and makes it easier to overheat sections of the commutator surface.

Choosing the stick, not just grabbing one

Most industrial suppliers offer several diameters and profiles of cleaning stick so you can actually reach the commutator while the motor stays in place. That’s not just about convenience; if the stick can’t sit flat in the track, it tends to polish the crown of the bars and ignore the edges, which is exactly where you need stable contact.

Behind the marketing language, you’re usually choosing between:

A relatively soft, fine abrasive bonded in a resin or similar matrix. The stick should be softer than the copper bars, so it wears instead of the commutator when you overdo it a little.

A composition that doesn’t leave conductive residue. EASA’s guidance on commutator and slip-ring cleaning calls out aluminum-oxide emery cloth as a poor choice because its conductive particles can embed in the surface and cause arcing. Commercial commutator sticks are formulated specifically to avoid that problem; they’re designed to clean without changing the electrical behavior of the track.

On small motors in hobby use, you’ll often see color-coded sticks: coarser for cleaning, finer for polishing. On larger DC machines, the choice tends to be diameter and length first, then grade. In either case, if you find yourself taking more than a very thin frosting of material off, you’re into commutator stone territory rather than cleaning sticks.

Where the cleaning stick actually fits among other methods

Here’s a compact comparison that shows what your stick is good at, and where other methods make more sense.

| Method | Material / Tool | Typical use case | Risk to copper & mica | Effect on brush film | Downtime & effort | When it’s the wrong choice |

| Commutator cleaning stick | Fine, non-contaminating abrasive stick | Light carbon build-up, pre-brush-change clean, minor spotting | Very low if used briefly with light pressure | Disturbs film slightly, usually evens it out | Short; can be done with motor in place | Deep grooving, loose bars, heavy burning, severe out-of-round |

| Commutator stone | Hand stone or in-place grinding stone | Removing minor ridges after machining, correcting uneven wear | Moderate; can remove metal quickly if overused | Can reset film completely, needs controlled run-in | Medium; more setup, more cleanup | Routine “between-runs” cleaning on otherwise healthy surfaces |

| Silicon-carbide / garnet paper | 150–200 grit paper or cloth | Final finish after turning, setting surface roughness | Moderate; safe if grit and time are controlled | Resets film; helps first film form uniformly | Higher; normally done during overhaul | Quick touch-ups in situ where dust removal is difficult |

| Common emery / sandpaper | Aluminum-oxide abrasive cloth/paper | General metalwork, not really intended for commutators | High; conductive grit can embed and cause arcing | Tends to damage film, raises risk of tracking | Misleadingly low; problems appear later | Any commutator or slip ring, unless the manufacturer explicitly approves it |

| Solvent / contact cleaner only | Contact cleaner or alcohol | Oil, dust, or moisture contamination with good film present | Very low; no abrasive | Leaves a sound film mostly intact | Very short; first step in most workflows | Burnt, scored, or uneven surfaces that need actual material removal |

| Cleaning carbon brushes | Brushes designed to clean while running | Removing localized burn spots and contamination during service | Low if used temporarily; they do wear the film | Can strip and rebuild film in a controlled way | Done under load, minimal extra downtime | Long-term use as “normal” brushes, or on already undercut film |

This is where the cleaning stick earns its keep: when you want less disruption than a stone, more than solvent, and a method that doesn’t require pulling the rotor or setting up a lathe.

Using the stick around brush replacement

Most suppliers who sell commutator sticks also quietly recommend the same simple rule: clean the commutator whenever you replace brushes. That’s especially true for appliance motors and fractional-horsepower drives where mechanical tolerances are small and carbon build-up has a noticeable effect on torque.

A practical sequence, stripped of ceremony, tends to look like this:

Brushes out. Springs relaxed. Existing dust blown or vacuumed away so you can actually see the film and the bar edges. If the film is healthy and uniform, cleaning might be limited to a solvent wipe and light stick work on any obvious high-resistance patches.

Stick applied with controlled pressure while the rotor is slowly turned. You’re aiming for a consistently dull, even track where the brush will run, not spotless bright copper everywhere. Once you reach that appearance, you stop; extra passes don’t bring extra benefit.

A careful cleanup to remove the fine abrasive and copper dust that every technical guide warns about. At this point, inspecting the mica undercut and checking for debris bridging the gaps is quick and cheap compared to coming back after tracking has started.

Then the new brushes go in, seated and run in according to the brush maker’s instructions, with spring pressure set in the recommended range for the application. Helwig’s commutator condition guides make it very clear that incorrect spring pressure is one of the main causes of brush and commutator failure, right up there with poor brush grade and poor surface condition. Cleaning the commutator but ignoring the springs is only half a job.

Mistakes that quietly undo good cleaning work

The cleaning stick is fairly forgiving, which is probably why it gets abused. A few habits tend to undo the benefits:

Removing every trace of film because “shiny copper looks better.” Film assessment charts from multiple manufacturers treat a medium brown film as the goal, not a defect.Stripping it back to bare metal every time forces the brushes to rebuild it from scratch and can shorten brush life.

Using the stick as a substitute for machining. If you can feel ridges with a fingernail, if the bars are visibly out of round, or if you’re seeing repeat patterns like heavy streaking or bar edge burning, the problem is no longer cosmetic. Guides on commutator wear link those patterns to load, brush alignment, and electrical issues, not just dirt.At that point, the stick only makes the surface look better while the underlying fault stays.

Pairing the stick with unsuitable abrasives. It’s common to see someone reach for generic emery cloth “for a quick touch-up” before using the stick. EASA’s advice against aluminum-oxide cloth is blunt: conductive grit left behind can cause arcing and damage. The whole reason the cleaning stick exists is to avoid that trap.

Skipping the cleanup. Technical documents spend a surprising amount of space reminding you to blow out abrasive and carbon dust after any dressing or seating operation. A commutator can look perfect and still have conductive sludge bridging mica gaps and sitting under the brushes. The cleaning stick didn’t fail there; the cleanup did.

So where does that leave the commutator cleaning stick?

The stick is a small, very specific tool: it lets you correct light surface issues, refresh the track for new brushes, and keep a decent film honest without dragging the machine back to a lathe every time. It works best when you respect its limits, read the film before touching anything, and treat the cleanup phase as part of the job instead of an afterthought.

Do that, and the commutator cleaning stick becomes less of a novelty accessory and more of a routine instrument: something that quietly keeps motors efficient, brushes predictable, and overhauls less frequent, one short and slightly dusty maintenance window at a time.