Commutator Arcing: Reading The Sparks Before They Destroy Your Machine

If you can easily see bright, persistent sparking at the brushes, the machine is already operating outside its safe comfort zone. Arcing is rarely “just the brushes”; it is the whole electromechanical system expressing stress at one very small interface. Read that interface well and you can fix problems upstream, not just polish them off the copper.

You already know what a commutator is, what commutation voltage is, and you’ve seen the diagrams in the standards. So this is not a tutorial. Think of it as field notes from someone who has stared at too many sparking machines and then measured what was really going on.

Table of Contents

What counts as “normal” arcing?

Total absence of visible sparks is nice on paper, but most working DC machines live with a faint, localized orange glow at the trailing edge of the brush. That’s acceptable. Many manufacturers and motor OEMs classify spark severity from essentially invisible up to “ring fire”, with the lower grades allowed for continuous operation and the upper grades treated as faults that demand a shutdown.

A useful way to think about it: if the commutator surface stays uniformly brown or light gray, any sparking you see is probably within design assumptions. Once you start getting black tracking, etched bars, or periodic dark and light segments, the arcs are doing mechanical and thermal work, not just carrying current for a few microseconds.

A quick visual reference table

The table below compresses several industry “spark level” schemes and common service practices into one view. It is not a standard; it’s a sanity check for technicians already familiar with OEM guidance.

| Observed arcing at brushes | Typical commutator appearance | Machine status in real life | Usual first action |

| No visible sparks, maybe a faint orange fuzz at the trailing edge | Uniform brown/bronze film, no black marks | Good. Run without special concern. | Log condition, keep existing maintenance interval. |

| Intermittent tiny sparks along part of brush edge | Very light tracks that wipe off easily, brushes clean | Still usually fine for continuous duty. | Inspect brush seating and spring pressure during next planned stop. |

| Continuous granular sparks along most of the brush width | Black marks that clean off with solvent, slight brush edge darkening | Borderline. Motor will run, but copper and carbon are eroding fast. | Schedule a stop, check load, brush grade, neutral position, commutator runout. |

| Thick bright sparks, sometimes “tails” wrapping around a bar or two | Localized burning, small pits, slot bar discoloration | Fault condition. Risk of flashover rises quickly with load steps. | Reduce load or stop. Inspect commutator geometry, undercut, interpole condition, and contamination. |

| Arc forms an almost continuous ring, or jumps to nearby metalwork | Heavy burning, melted edges, possibly cracked bars | Serious failure. Often called ring fire or flashover. | Trip the machine, determine cause before any attempt to restart. Plan for machining or major repair. |

If you habitually run at the third row or worse, you are trading copper and carbon for short-term production. That trade eventually fails on its own schedule, not yours.

Fast triage when you actually see the arc

When someone calls you to “come look at the sparking motor,” time is already being lost. The temptation is to stare at the commutator and adjust brushes until it looks nicer. That approach fixes symptoms, sometimes. But arcing is a symptom of either contact geometry, surface condition, magnetic conditions, or current waveform. Usually more than one.

A practical sequence, done with the covers off and the motor just long enough online to observe safely, tends to be: watch the pattern of the sparks relative to rotation; note whether they sit at the leading or trailing edge, or appear mostly at certain bars; watch what happens when load or speed changes; and listen for brush chatter. That short observation tells you whether to blame mechanics, magnetics, or the supply before a screwdriver ever comes out.

If the arc intensity rises sharply with speed but not with torque, commutator out-of-round, poor seating, or brush bounce move higher on the list. If it tracks torque or field weakening instead, commutation voltage and armature reaction are usually the main actors.

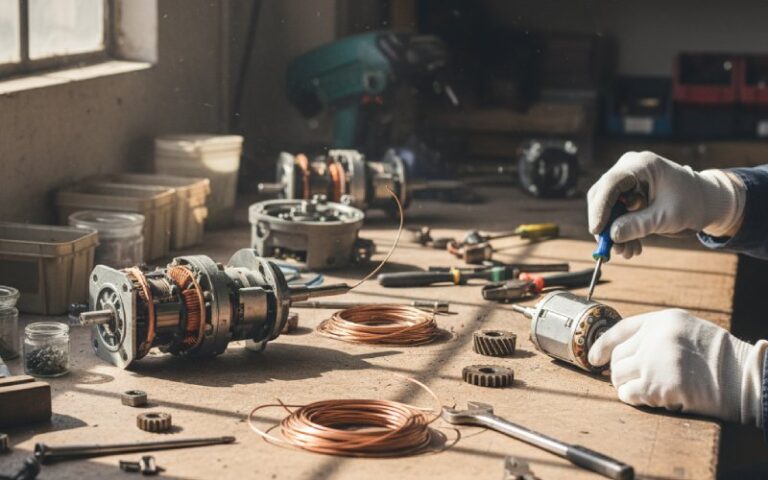

Contact mechanics: when the interface itself is wrong

The physical contact between brush and commutator is often blamed first, and often correctly. But it helps to split the problem.

One pattern is worn brushes producing low and uneven spring pressure, so the real contact area collapses into a few high-current spots. Those hot spots ignite arcs on every commutation event, and the commutator starts to show patchy track marks. Field experience and manufacturers both point to incorrect brush pressure as one of the common causes of visible arcing and eventual ring damage.

Another pattern is poor seating. New brushes that were never properly bedded, or old ones that have worn into a skewed wedge because the holder is misaligned, will ride on edges rather than a uniform film. That edge concentrates current, again raising local voltage across the part that actually lifts off the bar, and you get grainy, persistent sparking.

Brush holders set too far from the commutator let the brush tilt and vibrate. Too close, and carbon dust packs into the gap and causes friction and binding instead. Classic service guidance keeps holder faces in the range of roughly 1/16–1/8 inch from the commutator, depending on frame size; outside that, arcing complaints are very common.

Out-of-round commutators and poor dynamic balance add another layer. At speed, the brush is effectively riding a cam. It loses contact at the high spots, re-impacts, and every loss of contact is an invitation for an arc. Machining the commutator back to true on a lathe, followed by proper undercutting and polishing, is almost always recommended once pitting and uneven wear go beyond a very shallow roughness.

Surface condition, contamination and insulation details

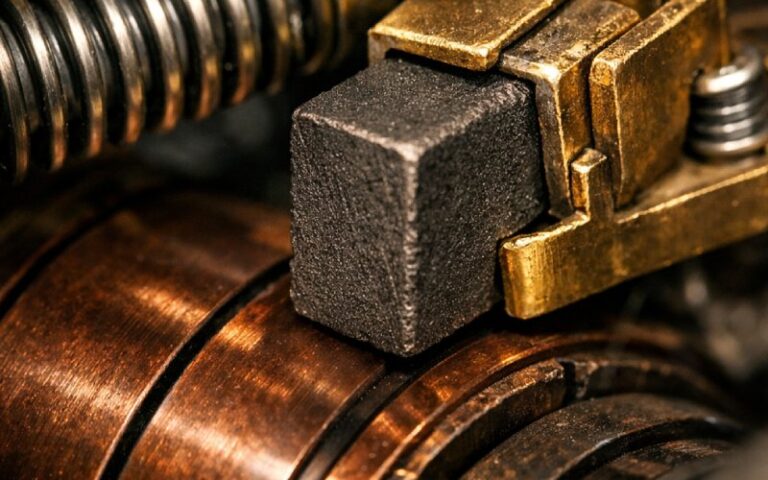

In practice, many bad arcs originate in the slots, not the surface you can easily see. Carbon dust, copper fines, oil mist and general debris pack into the undercut. That creates leakage paths between bars, which shift the effective commutation point and promote bar-to-bar arcing and sometimes ring fire.

High mica is another slow burner. When mica isn’t undercut adequately, its fins ride up to the brush path. The brush bumps on the mica instead of resting on copper, so contact is intermittent and the film never stabilizes. The result is vibration, sparking and often a regular pattern of burnt bars. Cutting back the mica and cleaning up copper burrs is usually enough to calm the arc, assuming the rest of the system is sound.

It is easy to underestimate contamination on the surface itself. A very thin oil film can improve brush life. A thicker or gummy film, sometimes produced by over-lubricated bearings or airborne process contaminant, drags under the brushes and creates uneven resistance around the circumference. Sparking follows the sticky spots. Systematic inspection of commutator films and careful cleaning are standard recommendations in maintenance bulletins for machines that live in dusty or oily atmospheres.

Electrical and magnetic causes hiding behind the sparks

Once the obvious mechanical and surface issues are ruled out, the remaining causes of arcing usually sit in how the magnetic circuit and the current waveform are interacting. The brush contact is just the observable boundary.

Field distortion and armature reaction are the classic explanations. At higher load, the armature’s own field distorts the main field and shifts the ideal commutation zone. Fixed brush gear then sits in the wrong place, so current reversal is incomplete and the trailing edge of the brush is still carrying significant current as it breaks contact. That’s voltage across a tiny gap, plus residual inductance, which draws an arc. Interpoles and compensation windings were invented to push back on this exact problem, keeping commutation spark-free across a range of loads.

Modern failure reports still show that weak or failed interpole windings, or incorrect field settings after rewinds, often present first as increased arcing at the commutator rather than as a neat resistance or insulation-test failure. In some studies, properly designed and healthy interpoles allow spark-free operation up to roughly 20–30% overload, while an identical machine without effective interpoles sparks much earlier.

Supply quality matters as well. DC drives with poor current regulation, mis-fired SCRs, or aggressive field-weakening programs create steep current edges and voltage spikes. Those spikes arrive exactly when brushes are transferring current between bars. The physics is simple enough: dI/dt is high, inductance is not zero, and the arc forms to satisfy the voltage requirement. Several motor service firms explicitly point to drive mis-settings and SCR faults as hidden causes behind “mystery” brush arcing and flashover on otherwise healthy machines.

When the arc level is tightly linked to field weakening or fast load steps from the drive, it is usually more productive to review drive parameters and field feedback than to change brush grades three times.

Environment, duty cycle, and the slow path to ring fire

Machines that live in mining, cement, pulp, or similar dusty environments tend to suffer from conductive films and packed undercuts. Over time this leads to leakage currents and arcs that can form almost continuous rings around the commutator. This “ring fire” is often triggered during a disturbance but built slowly by contamination and poor cleaning practices.

Repeated short-time starts, frequent reversals, and long idle periods under weak field can also promote arcing. Heat cycles and film disruption change brush contact conditions, and the armature never quite settles into a stable wear pattern. Some case studies on automotive and fuel-pump motors, for example, link accelerated brush wear under commutation arcs to high-frequency cycling even in benign atmospheres.

At the severe end sits flashover. Here, an arc either runs around the commutator face or from the commutator to nearby metal parts or brush gear. It is helped by contamination, high dv/dt, bad alignment, and often overloaded duty. Service organizations sometimes add sacrificial grounded metal near the commutator, giving an intentional low-impedance path for an arc to hit instead of burning brushboxes and copper to destruction.

Designing and specifying against arcing

If you are specifying or rebuilding machines rather than just maintaining them, a few design levers matter more than others.

Brush grade selection is usually decided from OEM data, but in practice many field retrofits switch grades to reduce arcing under a particular duty. Harder grades carry current well but can be unforgiving of commutator runout or contamination. Softer grades tolerate imperfect surfaces but may dust more and need tighter cleaning control. Application notes from brush manufacturers repeatedly highlight the trade between contact resistance, film-forming ability, and arcing tendency under different loads.

Commutation aids in the magnetic circuit—interpoles and compensation windings—are the second major lever. Correctly proportioned and connected, these windings generate a local EMF that opposes the armature’s reactance voltage during commutation. That reduces both the voltage across separating contacts and the drawn-arc energy. If a machine is being rewound for a new duty with more frequent reversals or deeper field weakening, revisiting interpole design data is often more effective than chasing brush wear afterward.

Mechanical accuracy is the third. Round commutators, true journals, correctly located brush gear, and reasonable balance are unglamorous, but they move the needle for arcing more than exotic brush grades in many cases. Industry guidance repeatedly stresses that once surface damage goes beyond very light marking, machining and undercutting are the proper cure; topical sanding without restoring geometry just resets the countdown for another failure.

Maintenance habits that actually change outcomes

Day-to-day practice often matters more than design for how much arcing you live with. Routine inspection of brush length, spring condition, commutator film, and undercut cleanliness sounds basic. In real plants it is often skipped until someone notices sparks or smell.

Service notes from several OEMs and repair houses highlight a few recurring patterns. Short brushes with weak springs cause both arcing and erratic torque. Neglected undercuts fill with carbon and copper dust, creating parallel paths between bars and encouraging ring fire. Abrasive paper is fine for very light film touch-up, but coarse paper or aggressive hand work can leave trenches and burrs that start the arcing problem you thought you were fixing.

Cleaning practices deserve more thought than they usually get. Dry compressed air alone tends to blow conductive dust deeper into crevices. Vacuuming with non-conductive tools, followed by careful wiping and inspection of slot bottoms, better supports stable, low-arc operation. In some industries, scheduled undercut cleaning is treated like lubrication: not optional, not cosmetic.

If a particular machine shows a steady trend from “almost no sparks” to “continuous granular sparking” over months, you are being given early warning long before insulation test results change. That is the phase where minor machining, brush replacement and drive checks are cheapest.

Diagnostics beyond “it’s sparking”

Experienced technicians rarely trust only their eyes. They combine visual assessment of arcing with a few quick measurements or tools.

A stroboscope lets you freeze the apparent position of sparks around the circumference and link them to specific bars, slots or geometric irregularities. This is especially useful for diagnosing slot bar marking or localized heating related to the first or last conductors in a slot passing under the brush at the wrong point in the commutation field.

Infrared checks of the commutator face and brushgear can identify areas where arcing is dumping extra heat, even when the sparks themselves are hard to see through covers. Trend plots of brush temperature or commutator surface temperature over time often show the onset of trouble before obvious sparking appears.

On larger industrial machines, temporary sensors on the brush arms (for current and vibration) can give a surprisingly direct view of commutation quality. Irregular brush current, high-frequency chatter, and sudden spikes at specific shaft positions correlate well with visual arc grading and with later findings during teardown in published studies on arcing and brush wear.

Bringing it together

Arcing at the commutator is not a standalone fault. It is how mechanical alignment, surface condition, magnetics, drive behavior, and environment show themselves in one narrow region of copper and carbon. When you look at the sparks, you are really looking at all of that.

If you treat every arcing complaint as “brushes again”, you will replace a lot of brushes and still see repeat failures. If you instead read the pattern of the arc, relate it to load and speed, verify geometry and cleanliness, and only then adjust brush grade or pressure, you will usually solve the underlying problem and stop seeing the same motor back in the shop.

That is the quiet target: not a perfectly clean commutator for a photograph, but a machine whose brushes run with only trivial, controlled sparking for years at a time. The sparks are your early-warning system. Use them before they choose their own shutdown date.