Cleaning Electric Motor Commutator Manufacturer in China

As China’s premier commutator manufacturer, XDC designs and produces high-precision commutators engineered to make cleaning and maintaining electric motor commutator surfaces faster, safer, and more predictable in your plant. Our commutators are widely used in DC motors, universal motors, traction motors and industrial generators, where reliable brush–commutator performance is critical.

Precision Components: Cleaning Electric Motor Commutators

Explore our comprehensive range of high-performance commutators designed specifically for cleaning electric motors. From compact hook types for handheld vacuums to robust multi-segment designs for industrial floor scrubbers, we provide precision solutions for every application. Engineered for durability and optimal conductivity, our cleaning electric motor commutators ensure efficient operation in demanding high-speed appliances. Contact us for custom specifications.

11.4mm OD 14-Bar Hook Commutator

Precision-engineered hook type commutator featuring a 14-segment design and 11.4mm outer diameter. Built for reliable conductivity and structural durability in DC motor applications.

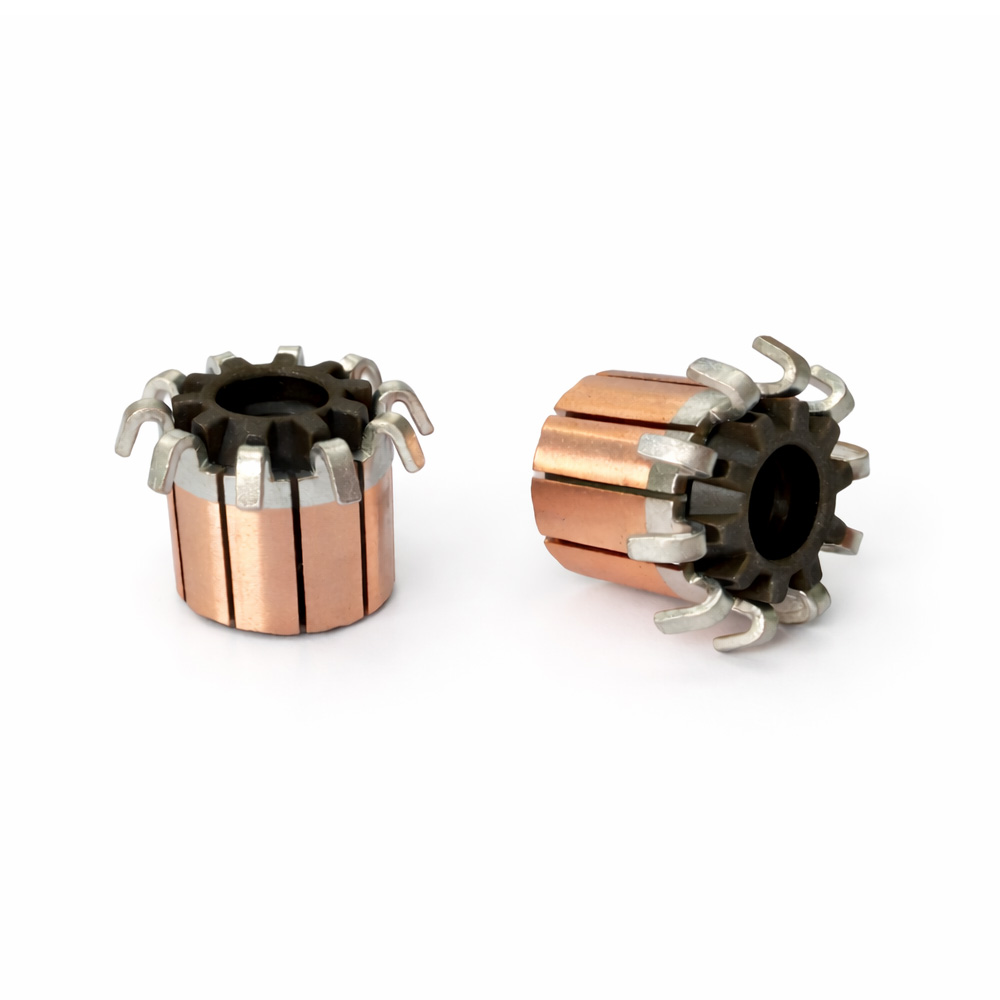

15.2mm 10-Bar Hook Commutator

Robust hook-style commutator featuring a 15.2mm outer diameter and 10 copper segments. Engineered for optimal electrical contact and durability in DC motor assemblies.

2.9mm 3-Bar Micro Commutator

Micro-sized hook commutator designed for miniature DC motors. Features a precision 2.9mm outer diameter and 3-segment construction, ensuring stable electrical transmission in compact assemblies.

3-Bar Right Angle Commutator

Specialized 3-segment commutator featuring a right-angle connection design. Precision-molded for specific micro-motor configurations requiring perpendicular wire termination and stable conductivity.

5.6mm 5-Bar Hook Commutator

Precision-crafted commutator featuring a 5.6mm outer diameter and 5-bar design. Ensures stable conductivity and long service life for small-scale DC motors.

7.6mm 3-Bar Hook Commutator

Durable hook-style commutator with a 7.6mm outer diameter and 3 copper segments. Designed for consistent electrical transmission in compact DC motor assemblies.

7mm 5-Bar Hook Commutator

Precision hook-style commutator featuring a 7mm outer diameter and 5-segment configuration. Designed for reliable conductivity and efficient performance in DC motor applications.

6.5mm 6-Bar Hook Commutator

Standard hook-style commutator featuring a 6.5mm outer diameter and 6-segment structure. Engineered for stable performance and reliable conductivity in small DC motor applications.

Precision Commutator Solutions for OEM Motor Manufacturers

As an OEM, you need every commutator to install easily, run smoothly and pass your outgoing inspection without rework. XDC focuses on the details that matter inside your production line:

Tight mechanical tolerances

We control commutator runout to ≤ 0.002 inch, helping you achieve smooth rotation, low brush vibration and consistent torque. This stability supports long-term brush performance and reduces the risk of sparking.

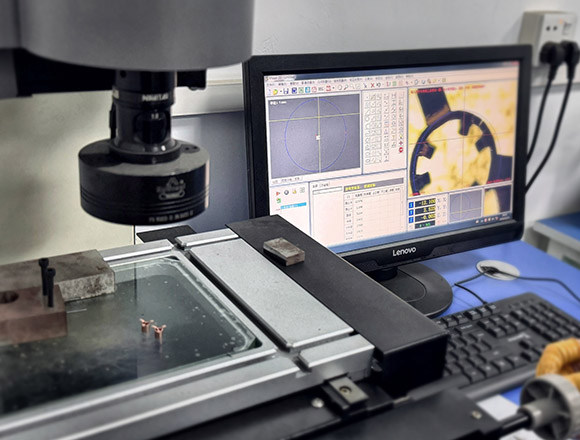

Uniform commutator bar geometry

Each commutator bar and commutator segment is machined using CNC equipment and verified for width, height and angle, ensuring even current distribution across the armature.

Optimized mica insulation and slot design

We precisely undercut and deburr mica insulation and commutator slots, then thoroughly clean the assembly to remove all burrs and dust. This stable geometry supports quiet operation.

Controlled surface finish

The final surface finish is designed to quickly form a thin, uniform copper-oxide film during motor run-in. A stable film improves brush contact, reduces localized heating and keeps the surface easy to restore if your customer ever needs cleaning electric motor commutator surfaces in service.

Maintenance-centric design philosophy

We design from the viewpoint of your service team. Smooth surfaces, clean slots, and stable geometry mean less time with garnet paper and commutator stones, and more time with your DC motors in operation.

Consistent quality across batches

Our quality system is built so that the commutator you receive next year matches the performance of the one you install today. This consistency is essential for fleet maintenance, where cleaning procedures must behave the same way on every unit.

Broad application coverage

XDC produces commutators for:

- Industrial DC motors and generators

- Universal motors for power tools and appliances

- Traction and heavy-duty electric machinery

In each segment, we align our design with relevant IEC / NEMA-style requirements and leading OEM practices.

Engineering support from China’s premier commutator manufacturer

Our engineers can advise on:

- Matching commutator specifications to your carbon brush grade

- Optimizing geometry for your cooling and dust-collection environment

- Setting inspection points that keep cleaning and visual checks straightforward

Complete In-Factory Testing

Every production batch is checked using a combination of mechanical and electrical tests:

- Runout measurement – confirming the ≤ 0.002 inch limit on finished commutators.

- Bar-to-bar testing – verifying that each commutator segment carries current consistently.

- Insulation resistance – confirming robust isolation between copper bars and the core.

By the time an XDC commutator reaches your assembly line, it has already passed the key checks that support stable motor performance and straightforward commutator cleaning procedures if required in the field.

Contact Us

Ready to source high-precision commutators from China’s premier commutator manufacturer?

Contact XDC today to discuss your drawings, technical requirements and annual volume:

- Request engineering support for a new DC motor or generator project

- Match an existing commutator sample with an equivalent XDC design

- Plan a long-term supply program tailored to your maintenance schedule

Our team will respond promptly with technical feedback, pricing and lead-time information so you can confidently specify XDC commutators in your next cleaning electric motor commutator-focused project.

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – XDC Commutators & Maintenance

Here you will find answers to the most common questions regarding our manufacturing processes, ordering details, and quality standards. If you have a question that isn’t listed here, please contact our sales team directly.

XDC commutators are manufactured with tight runout tolerances, carefully undercut mica and smooth bar edges. This makes it easier for your team to wipe the surface clean, use light non-conductive abrasives when needed, and re-establish a stable running film without deep rework.

Yes. As a dedicated commutator manufacturer, we can customize diameter, bar count, slot design, insulation system and mounting interfaces to match your motor design and your preferred commutator cleaning practices.

Our products are engineered for applications where dust, moisture or process contamination demand regular commutator maintenance. Robust bonding of commutator bars, controlled copper hardness and precise slot geometry help the surface withstand repeated cleaning and inspection.

XDC builds its process around widely recognized DC motor repair and overhaul specifications for runout, mica undercutting, bar chamfering and electrical testing, while applying our own FMEA-based improvements to reduce high-risk failure modes such as grooving and copper drag.

We regularly collaborate with OEMs and repair centers worldwide. Our engineers can provide guidance on inspection intervals, suitable tools and recommended surface conditions that are compatible with XDC commutators, helping you formalize a clean, repeatable maintenance standard.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…