Carbon Commutator Solutions for Fuel Pump and DC Motors

As China’s premier commutator manufacturer, XDC delivers high-reliability carbon commutator systems engineered for modern fuel, automotive, and industrial environments. Our designs are optimized for in-tank fuel pump motors, compact DC motors, and ethanol-compatible applications where conventional copper commutators struggle with corrosion, wear, and electrical noise.

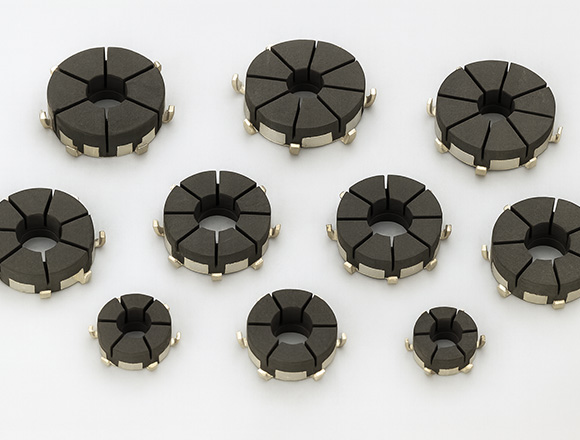

Carbon Commutator Manufactured by XDC

We excel at transforming your design specifications into high-performance components, prioritizing initial trial pieces for your approval before commencing high-capacity orders. Investigate our specialized carbon-based solutions below, and directly send us your drawings to get a quote.

Precision 10-Bar Carbon Commutator

The high-density 10-segment carbon surface delivers superior arc-quenching performance. This 23.2mm component is engineered with an optimized carbon-copper interface to ensure structural integrity and low-ripple commutation.

16.2mm 8-Segment Carbon Commutator

Featuring a high-performance carbon contact surface, this 16.2mm unit ensures superior wear resistance and EMI suppression. Ideal for fuel pumps and applications requiring chemical compatibility and minimal arcing.

8-Bar Carbon Commutator

Engineered with carbon segments for superior thermal stability, this 23.2mm unit resists electrical pitting during high-current switching. It delivers a robust contact solution for extended motor durability.

12-Segment Carbon Commutator

Featuring a 12-segment layout on a 23.2mm OD, this carbon unit optimizes thermal load distribution. It ensures ultra-smooth current transition and precise commutation for high-performance DC motors.

Key Features & Benefits

Each XDC carbon commutator is engineered as an integrated system with the armature winding and carbon brush set:

Corrosion-resistant design

Carbon or carbon-surfaced segments resist aggressive gasoline and ethanol fuels that rapidly attack copper commutators.

Optimized for fuel environments

Geometry, segment count, and undercut dimensions are tuned to stabilize arc duration and minimize surface damage depth under real fuel-pump loads.

Lower wear, longer life

By pairing the right carbon grade with the commutator and brush holder design, we help customers stay near the low-wear regime demonstrated at 5–7 A instead of the high-wear region near 10 A.

High-speed stability

XDC designs support demanding spin-test RPM and temperature requirements for automotive in-tank fuel pump modules.

Reduced electrical noise

Carbon contacting surfaces and optimized commutation improve EMI/RFI behavior compared with many copper commutator solutions.

Cost-effective upgrade

Component-level cost is a fraction of total pump value, allowing you to offer E10/E85-compatible, long-life products with a manageable BOM increase.

Technical Snapshot

We can tailor designs around ranges such as:

- Outside diameter: ~20–30 mm (fuel pump class); custom sizes on request

- Segment count: typically 6–12 segments for small DC motors and fuel pumps

- Carbon material: tailored resistivity, hardness, and bending strength based on your load and environment

- Operating currents: optimized from low-current efficiency applications up to high-current, high-inductance fuel-pump duty cycles

- Compatible brush types: carbon, metal-graphite, or hybrid brush grades with optimized spring forces

Share copper commutator drawing, and we will recommend an XDC carbon commutator configuration that meets your life and cost targets.

Why Choose XDC

As China’s premier commutator manufacturer, XDC combines advanced materials engineering with large-scale production capability:

Customized engineering support

Our team works with your engineers on bar count, OD/ID, insulation class, run-out tolerance, and brush specification to ensure that the carbon commutator and carbon brush set achieve the required life and efficiency targets.

Strict quality control

100% visual inspection, spin testing at specified RPM and temperature, and bar-to-bar dielectric tests help ensure consistent performance in every batch.

Cost-optimized manufacturing

Using high-volume, automated molding and machining for molded commutator segments, we offer competitive pricing while maintaining tight dimensional tolerance and stable electrical properties.

Global supply capability

With robust export experience, XDC supports automotive, industrial, and aftermarket customers worldwide with reliable lead times and comprehensive documentation.

Typical Applications

XDC supplies carbon motor commutator solutions and assemblies to OEMs and Tier-1 suppliers worldwide in applications such as:

Automotive in-tank fuel pump motor

Motorcycle and ATV pumps

Compact DC motors for small appliances

Specialty pumps for corrosive

Custom DC motor projects

Contact Us

Ready to upgrade your fuel pump motor or DC motor platform with advanced carbon commutator technology?

XDC – China’s Premier Commutator Manufacturer

- Share your drawings

- Please let us know any other requirements you have for this product.

- Arrange a technical meeting between your engineering team and our commutation specialists.

Get in touch today and let XDC design and manufacture the next generation of reliable, ethanol-compatible commutators for your global applications.

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

XDC Commutator - FAQ

In many cases, yes—but we recommend a design review. A carbon commutator behaves differently from copper in terms of contact resistance, filming, and wear. We typically adjust brush grade, spring force, and sometimes bar count or diameter to ensure stable commutation and long life in fuel.

Independent automotive sources report fuel pumps using carbon-surfaced segments achieving up to around 10× longer life in gasoline compared with conventional copper designs, along with lower power consumption. Actual life depends on your current, inductance, fuel chemistry, and pump duty cycle; we can help you model and test this.

High-alcohol fuels such as E10 and especially E85 are more conductive and corrosive than pure gasoline. Industry practice is to adopt carbon-surfaced commutator segments in E85-capable pumps to prevent accelerated corrosion and erratic commutation. For global platforms, many OEMs choose carbon technology even for regular gasoline to simplify sourcing and improve robustness.

Yes. To fully exploit the benefits of a carbon commutator, we work with your team on brush selection, armature inductance, commutator geometry, and testing protocols. Our goal is to deliver a complete commutation system, not just a single component.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…