Car Commutator Manufacturer in China

As China’s premier commutator manufacturer, XDC specializes in high-performance car commutator solutions for OEM and aftermarket customers worldwide. Every car commutator we produce is engineered for stable current switching, low brush wear, and long-term reliability in demanding automotive environments.

Custom Car Commutator Solutions

If your project requires more than a catalog part, XDC offers fully customized car commutator development:

- Optimized copper segment geometry for special torque or speed ranges

- Customized mica insulation thickness and undercut depth

- Specific brush grades and spring forces matched to your car commutator design

- Armature–commutator assembly supply to simplify your supply chain

From initial concept to PPAP and mass production, we provide engineering support and testing reports that reflect true automotive standards.

Car Motor Commutators by XDC

Explore our car commutator range for brushed DC motors used in automotive systems. We supply copper commutators in multiple outer diameters and segment counts, with common terminal styles such as hook and tang for secure winding connection. Options cover micro to larger motor sizes and support stable commutation in compact assemblies. Custom specifications are available for OD, segments, bore, and terminal form to match your motor design requirements.

5.6mm 5-Segment Commutator

5-segment micro commutator with 5.6 mm outer diameter. Copper segments on an insulated hub with hook terminals, built for compact brushed DC motors and consistent current switching.

370 Motor Commutator

Commutator designed for 370-size brushed DC motors. Copper segments on an insulated sleeve with tang terminals for coil connection, providing reliable current switching in compact motor assemblies.

7.6mm 3-Segment Commutator

3-segment commutator with 7.6 mm outer diameter. Copper segments on an insulated hub with coil terminals, suited for small brushed DC motors requiring stable commutation.

7mm 5-Segment Commutator

5-segment commutator with 7 mm outer diameter. Copper segments on an insulated hub with hook terminals for winding connection, designed for compact brushed DC motor commutation.

6.5mm 6-Segment Commutator

6-segment commutator with 6.5 mm outer diameter. Copper segments on an insulated hub with hook terminals, engineered for smooth commutation in small brushed DC motors.

2.9mm 3-Segment Commutator

Ultra-compact 3-segment commutator with 2.9 mm outer diameter. Copper segments on an insulated sleeve with tang terminals, suited for miniature brushed DC motors and tight assemblies.

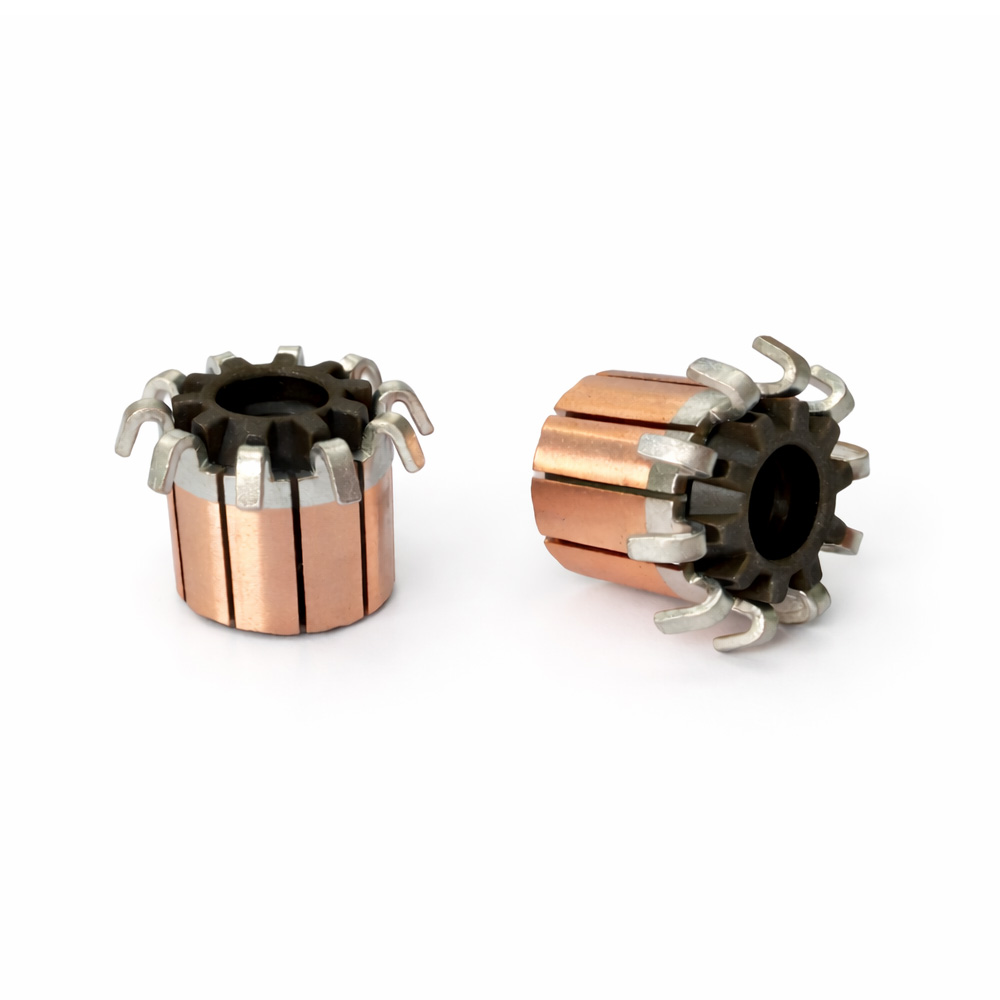

15mm 10-Segment Commutator

10-segment commutator with 15 mm outer diameter. Copper segments on an insulated hub with multiple hook terminals, designed for higher pole-count brushed DC motors and stable commutation.

15.2mm 10-Segment Commutator

10-segment commutator with 15.2 mm outer diameter. Copper segments with welded tang terminals on an insulated hub, suitable for brushed DC motors needing secure winding connections and stable commutation.

Precision Car Commutator Design & Specifications

At XDC, the car commutator is treated as a critical precision component, not a consumable accessory. Our engineering team designs each car commutator around your motor’s armature, brush system, and load profile to ensure optimal performance and long service life.

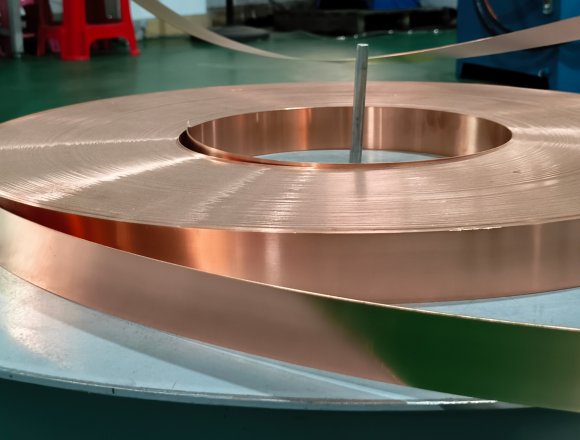

High-purity copper segments

Each car commutator uses oxygen-free copper bars with tightly controlled conductivity and hardness. We manage bar geometry and surface roughness so that carbon brushes seat quickly and run with minimal arcing.

Mica insulation & slot integrity

Between commutator segments, we use high-grade mica insulation and precise undercutting to maintain consistent dielectric strength and stable commutation, even at high current densities.

Controlled wear & erosion benchmarks

In endurance testing, we track commutator segment erosion depths in the range of 45–75 µm over standardized test runs. This data-driven limit helps ensure that every car commutator maintains a clean, round contact surface over its designed life, rather than developing grooves or bar-edge burning.

Brush–commutator pairing expertise

We select and validate carbon brush grades specifically for our car commutator designs. Internal testing shows that using optimized brush materials and finishes can significantly reduce wear and arc duration, particularly in high-current DC starter motors and fuel pump motors.

Automotive-specialized engineering team

Our R&D team focuses on automotive commutator design – from starter motor commutators to blower and wiper motor units. We understand how armature winding layout, brush holder geometry, and load profiles interact with the car commutator, and we design accordingly.

Advanced machining & finishing

Each car commutator is machined on specialized commutator lathes with strict control of:

- Outside diameter and concentricity

- Segment height tolerance

- Runout and roundness

After turning, we use dedicated polishing stones and gauging equipment to deliver a smooth, consistent surface finish that promotes stable brush contact and low sparking.

Robust quality control

Our quality system for car commutator production includes:

- 100% electrical testing on critical batches: continuity across segments, insulation resistance to shaft/core, and high-voltage withstand tests.

- Dimensional checks on OD, ID, length, and bar count to match your armature design exactly.

- Dynamic balancing of armature–commutator assemblies where requested, reducing vibration and improving brush life.

This ensures that each car commutator leaving the XDC plant meets your drawing and functional requirements, not just nominal catalog specs.

OEM, aftermarket & custom flexibility

Whether you need an OEM starter motor commutator, a replacement car commutator for aftermarket kits, or a fully customized design for a new platform, XDC can support:

- Low-volume prototypes and validation samples

- Medium-volume production for niche models

- Large-scale series for high-volume passenger cars and commercial vehicles

Our tooling and process team can quickly adapt to new designs without compromising control over quality.

Manufacturing & Quality Control for Every Car Commutator

We structure every car commutator project around a clear production and testing plan.

Material traceability

All copper, mica, and resin materials in your car commutator can be traced back to approved suppliers with full documentation. This is vital for consistent performance in automotive electrical systems.

Process stability

Critical processes for each car commutator—such as bar pressing, soldering/brazing, resin curing, and turning—are monitored using SPC (statistical process control). Deviations are flagged before they affect finished components.

Life and wear evaluation

Instead of relying only on visual checks, we measure:

- Brush wear rate against the car commutator

- Surface roughness and circularity before and after test runs

- Arc behavior at specified current and voltage conditions

This allows us to tune the design and process until the car commutator demonstrates stable behavior over the intended operating window.

Contact Us – Partner with XDC for Your Next Car Commutator Project

Ready to source a reliable car commutator from a dedicated Chinese manufacturer?

XDC’s technical and sales teams are available to support:

- New platform development

- Localization of existing car commutator designs

- Cost-optimized alternatives without sacrificing performance

- Long-term supply agreements for OEM and aftermarket programs

Contact us today with your drawings, samples, or target specifications, and we will provide a tailored car commutator proposal with clear lead times, tooling plans, and quality documentation.

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Car Commutator & Automotive Commutator Questions

Here you will find answers to the most common questions regarding our manufacturing processes, ordering details, and quality standards. If you have a question that isn’t listed here, please contact our sales team directly.

Our automotive commutator designs for starter motors use high-conductivity copper bars, robust mica insulation, and precisely controlled runout. We validate each starter-style car commutator under high-current test conditions, monitoring brush contact, temperature rise, and surface condition to ensure reliable cranking performance.

Yes. We regularly supply starter motor commutator and blower motor commutator solutions based on customer drawings or samples. Our engineers can adjust bar count, outer diameter, bore, and keyway dimensions, and we can recommend brush materials that match your car commutator requirements.

As a specialized commutator manufacturer, XDC applies strict incoming material checks, in-process inspection, and final 100% testing on critical electrical parameters. Each car commutator batch is traceable, and we maintain detailed inspection records, from dimensional data to electrical test results.

Absolutely. We supply car commutator products for OEM starter motors, blower motors, and wiper motors, as well as aftermarket replacement parts. Our production system can handle both high-volume OEM schedules and flexible aftermarket orders.

Simply send us your motor drawings, photos, or a sample car commutator, along with your performance targets. Our technical team will review the data, propose a matching or improved design, and advise on materials, dimensions, and test methods to ensure your car commutator meets its intended application.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…