Brushed Motor Commutator Manufacturer in China

As China’s premier commutator manufacturer, XDC designs and produces a complete brushed motor commutator range for industrial DC drives, traction motors, universal motors, power tools, starter motors and compact gear motors. We combine advanced materials, precision machining and data-driven engineering to reduce sparking, extend brush life and improve reliability in your DC machines.

What Makes an XDC Brushed Motor Commutator Different?

At XDC, we don’t treat the commutator as just a copper ring with slots. Every design starts from the complete brush–commutator–armature system:

- Optimized copper segments and mica insulation to ensure stable commutation at high speed.

- Careful matching of carbon brush grade, brush holder geometry and spring pressure.

- Tight control of commutator surface finish and runout to minimize friction, noise and brush dust.

Brushed Motor Commutators by XDC

Our product range covers cylindrical and flat commutators in multiple diameters and segment counts, suitable for micro to medium DC motors. Copper segments with molded insulation and hook or riser designs support stable current transfer and reliable coil termination. Options fit applications such as power tools, household appliances, automotive components, and small precision devices. Designs can be adapted to match specific rotor dimensions, performance requirements, and assembly methods.

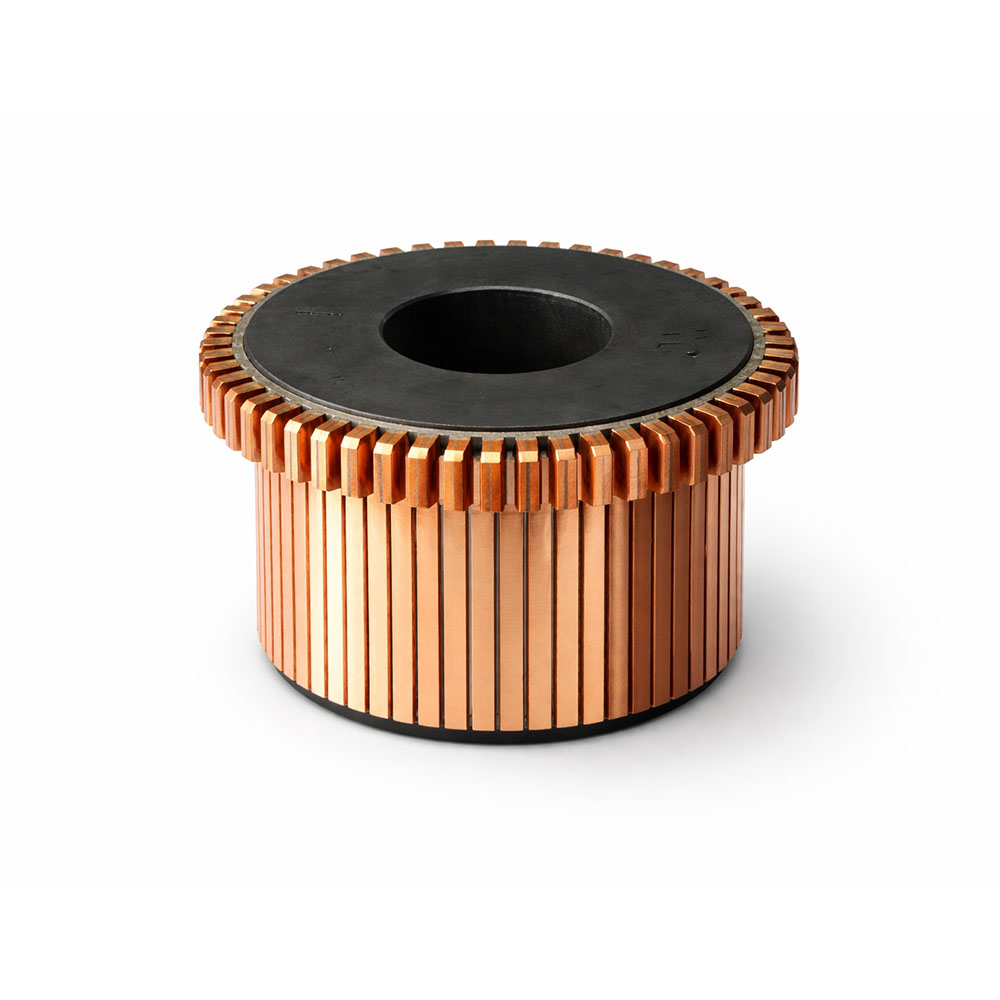

95.4mm 57-Segment Motor Commutator

Segmented copper commutator for DC machines; 95.4 mm outer diameter and 57 bars provide stable current transfer, good balance, and reliable performance in medium-size motors and generators.

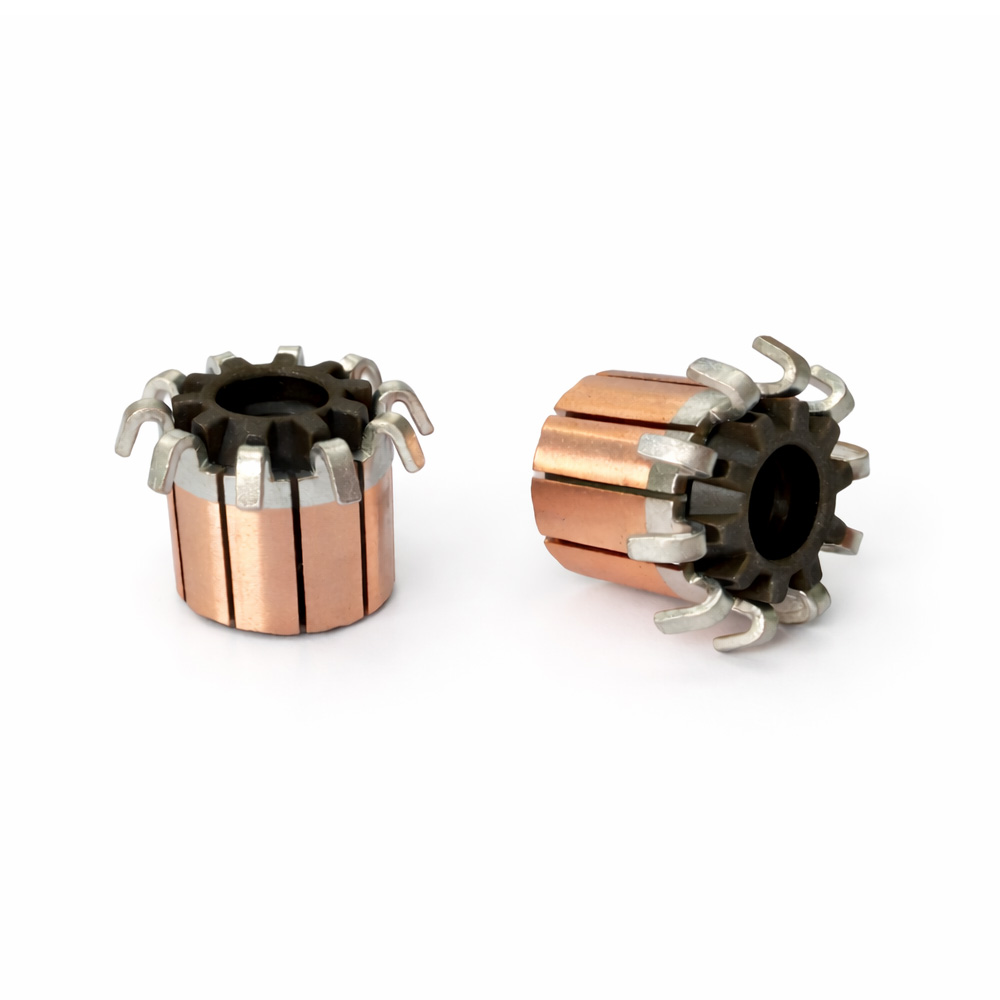

15.2mm 10-Segment Hook Commutator

Compact copper hook-type commutator with 15.2 mm outer diameter and 10 segments, suitable for small DC motors requiring reliable current transfer and easy coil connection.

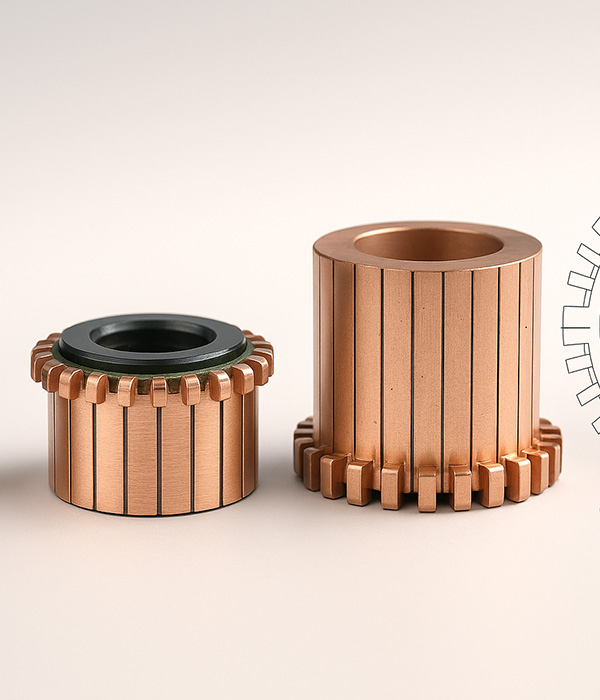

370 Motor Cylindrical Copper Commutator

Molded plastic hub with copper segments, designed for 370-size DC motors, providing stable commutation in compact power tools, toys, and automotive applications.

15mm 10-Segment Hook Commutator

Compact hook-type copper commutator, 15 mm outer diameter with 10 segments, for small DC motors requiring stable current transfer and convenient coil connection.

47.6mm 16-Segment Hook Commutator

Flat copper hook-type commutator with 47.6 mm outer diameter and 16 segments, suitable for medium DC motors requiring reliable commutation and convenient coil termination.

23.2mm 12-Segment Hook Commutator

Disc-type hook commutator, 23.2 mm outer diameter with 12 segments and molded insulation, suited for compact DC motors needing stable commutation and straightforward coil termination.

7.6mm 3-Segment Hook Commutator

Miniature copper hook-type commutator, 7.6 mm outer diameter with 3 segments, for micro DC motors needing stable current transfer in limited space.

6.5mm 6-Segment Hook Commutator

Ultra-compact copper hook commutator, 6.5 mm outer diameter with 6 segments, suitable for micro DC motors requiring precise commutation in space-constrained designs.

Standard for XDC Commutator Machining

Each brushed motor commutator from XDC is engineered using these proven ranges as design anchors, then customized for your specific load profile, environment and duty cycle.

Surface roughness control

- Commutators are finished to about 0.9–2.0 μm Ra, with a targeted profile of roughly 100 peaks per centimetre.This range supports fast formation of a stable carbon film without excessive friction. Too smooth (below ~0.4 μm) or too rough (above ~2 μm) is avoided because both lead to abnormal wear and commutator sparking.

Geometric precision (ovality and runout)

- XDC production lines hold commutator TIR to ≤0.05 mm and bar-to-bar height deviations to strict internal limits, reducing the risk of flashover and uneven brush wear.

Why Choose Us – XDC, China’s Premier Commutator Manufacturer

When you choose XDC, you’re choosing a partner that understands both theory and real-world constraints.

Deep engineering know-how

Our team is fluent in armature reaction, commutation theory and practical FMEA (Failure Mode and Effects Analysis) for DC machines. We design to recognized industry practices and can manufacture to align with common standards such as IEC 60034 and relevant NEMA guidelines on request.

Precision manufacturing and testing

• CNC machining and dedicated commutator lathes for tight cylindricity and balance.

• Surface roughness and roundness measured on every batch, not just first-off samples.

• Electrical tests including bar-to-bar resistance checks, insulation resistance and high-potential tests to verify insulation integrity.

Optimized materials for long life

• Premium copper alloys and high-quality mica insulation for thermal stability.

• Multiple carbon brush compatibility options (electrographitic, resin-bonded, metal-graphite) to suit your operating envelope.

• Guidance on brush grade selection so your commutator and brushes work as a system.

Applications for Our Brushed Motor Commutator

Whether you’re replacing a worn dc motor commutator segment or developing a new platform for an OEM product, XDC can match dimensions, performance and life expectations—or improve them. XDC supplies custom and standard commutators for:

Industrial DC motors

Rolling mills, extruders, cranes, winches and hoists using series or compound DC machines.

Traction motor commutators

DC traction motors on locomotives, mining haul trucks and rail vehicles where high current density and shock loads are common.

Universal motors and power tools

Compact commutators for power tools, vacuum cleaners and small appliances with high-speed armature winding designs.

Starter motors and automotive DC motors

Robust commutators for starter motors, blower motors and auxiliary drives.

Hobby, RC and gear motors

Small-diameter units for RC brushed motors, low-voltage permanent magnet DC motors and precision gearmotors.

Contact Us

Ready to upgrade reliability, reduce downtime and optimize your brushed motor commutator design?

Get in touch with XDC, China’s premier commutator manufacturer:

- Share your motor commutator drawings.

- Please provide us with additional information about this product, such as materials, quantity, etc.

- Request a quotation for prototypes, small batches or large-scale production.

Contact us today to discuss how XDC can support your next DC motor, traction system or power tool platform with precision-engineered commutator solutions.

WhatApps

+86 17820674273

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Brushed Motor Commutator Basics

A light, intermittent “ring” of very small sparks is common in many DC motors. However, continuous bright arcs, ring fires or sparking that grows with load or speed indicate a problem—often related to brush grade, spring pressure, contamination, poor surface finish or excessive runout. XDC designs commutators and recommends brush combinations that keep sparking within safe, predictable limits.

Our standard finishing targets a roughness range of approximately 0.9–2.0 μm Ra for most industrial and traction commutators, with tighter ranges available for small high-speed units. This supports a stable graphite film, fast run-in and low wear for both brush and copper segments.

Yes. With dimensions, drawings or samples, we can produce compatible replacements and often improve aspects such as commutator runout, surface roughness or bar insulation. For fleets, we can propose upgrades that reduce failure modes like pitting, grooving and flashover.

We regularly supply commutators for humid tropical climates, dusty mining operations and heavy-duty traction equipment. For hazardous locations, we work with your engineering and safety teams to select appropriate brush materials and ensure the commutator design supports your protection concept and local regulations.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…