Armature Commutator Manufacturer in China

XDC is a dedicated armature commutator manufacturer in China, focused on designing and producing high-precision commutator assemblies for DC motors, DC generators, and universal motors. Each armature commutator is produced in-house from selected copper and insulation materials, using controlled machining, armature–commutator alignment and inspection procedures to deliver stable commutation, low wear and reliable service life for your equipment.

Armature Commutator Design & Construction

XDC designs each armature commutator as a robust rotary electrical interface between the armature winding and the external circuit:

- Commutator segments (bars) High-conductivity copper segments machined to tight tolerances for uniform voltage drop and smooth current distribution.

- Insulation system Mica or advanced resin insulation between commutator segments and between the commutator hub and rotor shaft to withstand high thermal and electrical stress.

- Armature commutator connection Each segment is connected to armature coils (lap winding or wave winding) through brazed or welded risers, ensuring low-resistance paths and stable armature current reversal.

- Carbon brush interface Our commutators are optimized for carbon, metal-graphite, or silver-graphite brushes, with carefully controlled commutator diameter, length, and track width to maintain a stable brush contact pattern.

This construction enables the armature commutator to support unidirectional torque in DC motors and mechanical rectification in DC generators while minimizing sparking and wear.

Precision Armature Commutators by XDC

Explore our comprehensive range of commutators designed for diverse DC motor applications. We offer various configurations including hook, riser, and planar types, with diameters ranging from micro 5.6mm units to industrial 95.4mm components. Manufactured with high-conductivity copper segments and reinforced insulation, our selection supports automotive, power tool, and appliance industries. Whether for OEM manufacturing or armature repair, find the exact specification required for reliable motor performance.

49mm 16-Segment Planar Commutator

Face-type construction featuring 16 copper segments and 49mm outer diameter. Includes peripheral tangs for secure winding connections, designed for flat DC motor applications.

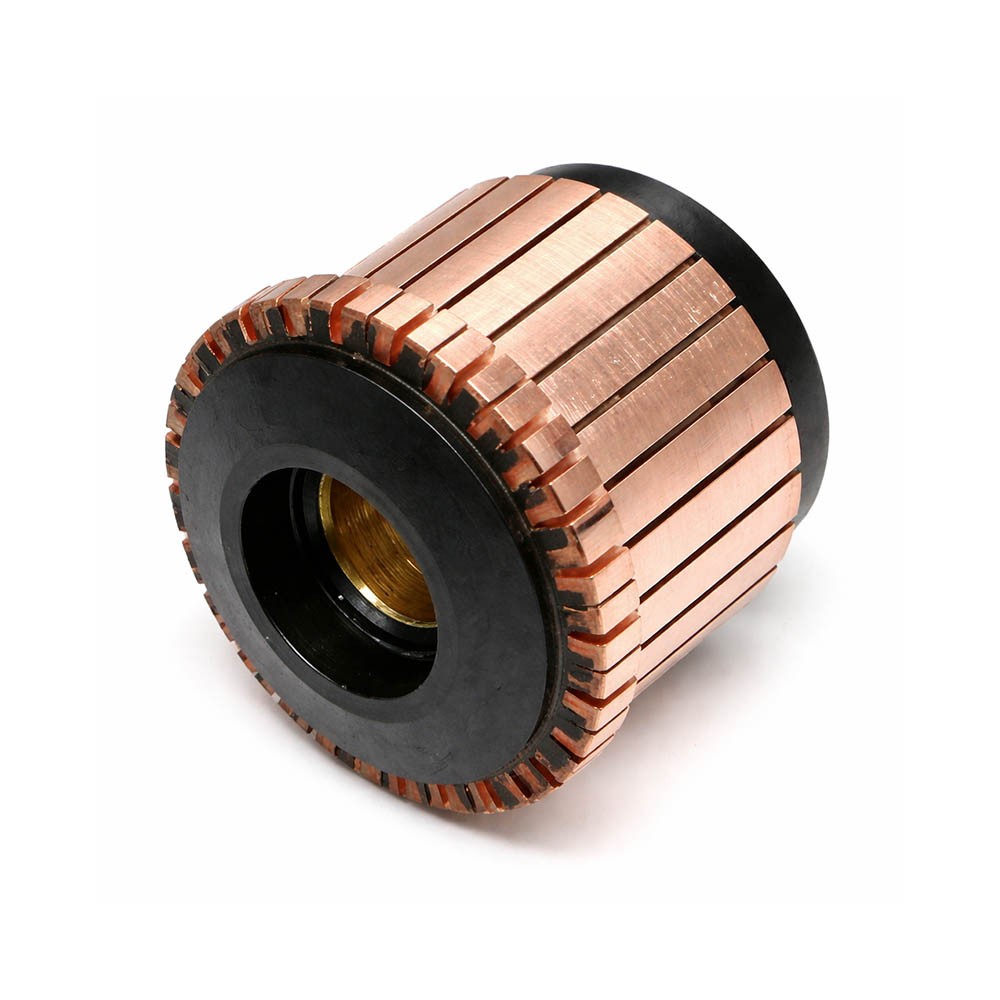

42mm 28-Segment Cylindrical Commutator

Barrel-type design featuring 28 copper segments and a 42mm outer diameter. Equipped with a reinforced brass bushing bore and slotted connections for precise armature winding.

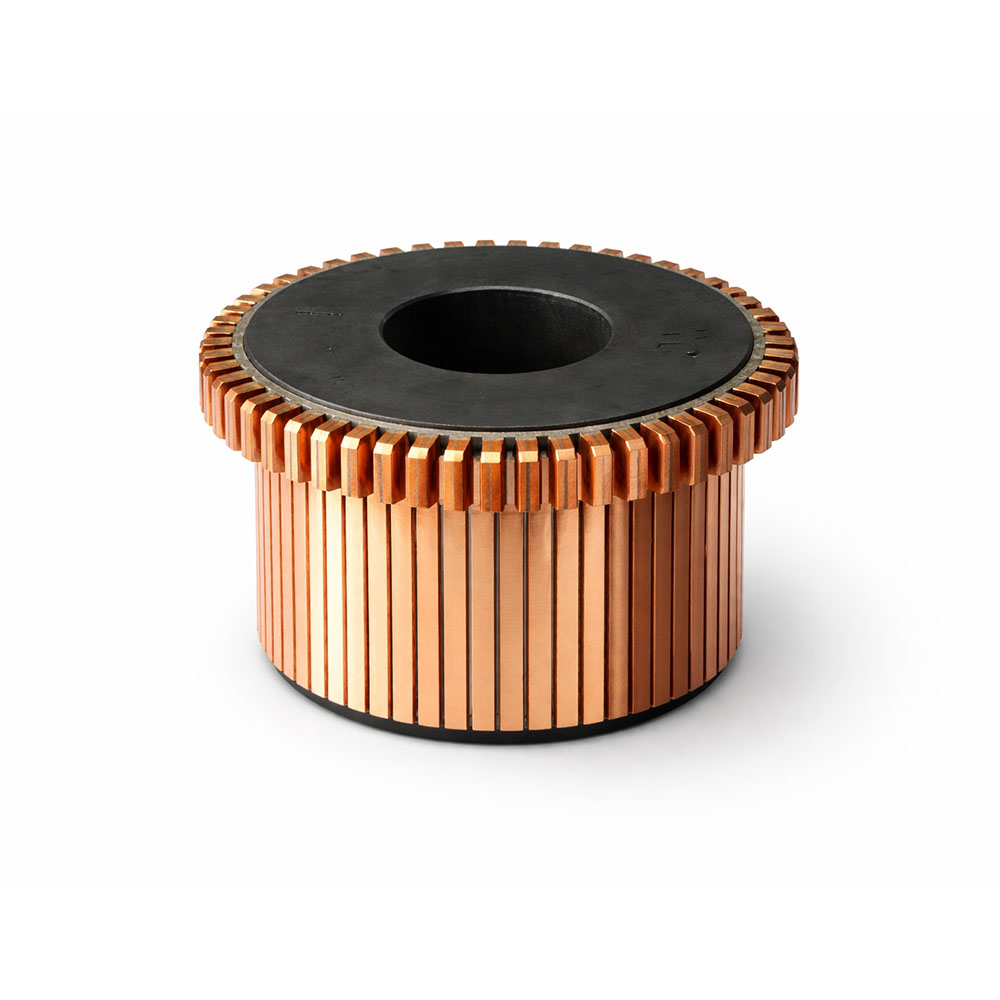

95.4mm 57-Segment Riser Type Commutator

Heavy-duty barrel construction with 95.4mm OD and 57 segments. Features stepped copper risers for robust welding connections, engineered for high-current industrial or traction motor armatures.

5.6mm 5-Segment Micro Hook Commutator

Miniature cylindrical unit with 5.6mm OD and 5 segments. Features extended radial tabs for winding connections, optimized for coreless or precision micro-motor armatures.

7mm 5-Segment Hook Type Commutator

Cylindrical design featuring 5 segments and a 7mm outer diameter. Incorporates integrated copper tangs (hooks) for reliable wire termination, suitable for compact DC motor applications.

7mm 5-Segment Hook Type Commutator

Cylindrical design featuring 5 segments and a 7mm outer diameter. Incorporates integrated copper tangs (hooks) for reliable wire termination, suitable for compact DC motor applications.

370 Series DC Motor Hook Commutator

Standard cylindrical armature commutator designed specifically for 370-size DC motors. Features integrated hook-type tangs for efficient winding and secure wire termination during motor assembly.

11.4mm 14-Segment Hook Type Commutator

Cylindrical unit featuring 14 copper segments and 11.4mm OD. Designed with robust hook-style tangs for secure wire fusing or welding, ideal for automotive and power tool DC motors.

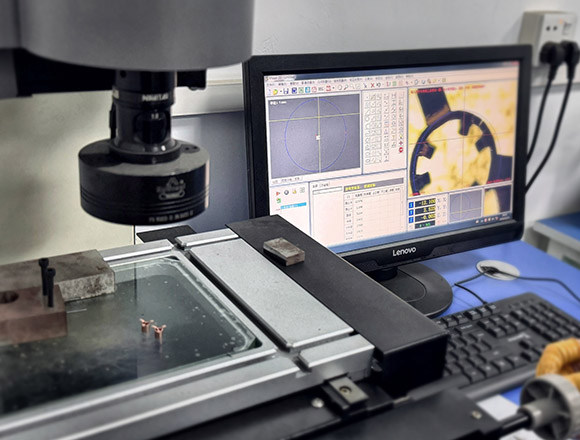

Manufacturing Process & Quality Control for Armature Commutators

To turn these specifications into reliable hardware, XDC applies a controlled, traceable manufacturing process for every armature commutator:

Segment manufacturing & assembly

Precision machining of copper bars and commutator hub for concentricity and minimal run-out. Controlled mica undercut and beveling tailored to your brush width and grade.

Armature and commutator alignment

The armature commutator is pressed and keyed to the rotor shaft, then dynamically balanced with the armature core laminations to reduce vibration and prevent bar-edge burning or copper drag during operation.

Electrical verification

Bar-to-bar tests and spanned-bar checks to detect unequal segment resistance or armature coil faults. Insulation tests to confirm mica and slot insulation integrity before impregnation.

Surface conditioning

Final armature commutator turning and fine dressing achieve the smooth profile and patina-ready surface required for proper brush film formation, reducing the likelihood of localized overheating and early commutation marks.

Data-backed engineering

Our designs are based on defined ranges for brush current density, peripheral speed and brush pressure, so every armature commutator is matched to your electrical and mechanical requirements instead of being built on trial-and-error.

Stable production and strict quality control

From segment machining and armature commutator turning to dynamic balancing and bar-to-bar electrical checks, we apply standardized processes and 100% inspection of key dimensions and resistance values. This helps keep run-out, bar height differences and contact surfaces within tight tolerances, ensuring consistent quality from samples to mass production.

Custom fit to your armature and winding

Whether your armature winding is lap or wave, and whether the machine is a DC motor, DC generator, traction motor or universal motor, XDC configures the armature commutator connection layout, segment count and riser structure to match your voltage, speed and current profile.

Contact Us for Custom Armature Commutator Projects

If you need a new armature commutator, an upgrade to an existing DC machine, or a matched commutator for a redesigned armature winding, XDC can support you from design review to volume production.

Contact Us (XDC – China):

- Please send us your product drawings.

- Please inform us of the quantity you require, the materials needed, or any special requirements for packaging, marking, or testing.

Our engineering team will respond with a manufacturable armature commutator proposal, complete with recommended materials and inspection items.

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Armature Commutator Applications & Maintenance

Here you will find answers to the most common questions regarding our manufacturing processes, ordering details, and quality standards. If you have a question that isn’t listed here, please contact our sales team directly.

Armature commutator turning is the precision machining of the commutator surface on a lathe to restore roundness, correct run-out, and remove surface defects such as grooves or bar-edge damage. At XDC, we allow for remachining allowances in the commutator design so that multiple light turnings can be performed over the life of the machine without compromising segment integrity.

An armature commutator connection links each commutator segment to one or more armature coils. XDC designs coil-end risers, brazed joints, and segment counts according to your chosen lap or wave winding, ensuring uniform current distribution and balanced magnetic fields across the armature. This reduces commutation imbalance and helps avoid surface patterns such as slot-bar marking.

For how to repair armature commutator assemblies, XDC recommends an engineering-led approach:

- Inspect run-out, bar lift, and mica undercut.

- Evaluate brush wear patterns and contact footprint.

- Decide whether corrective actions should be limited to light stoning, armature commutator turning, or full commutator replacement.

We can support you with repair drawings and machining limits so local service shops can work to XDC specifications.

In armature vs commutator terminology:

- The armature is the rotating assembly carrying the core laminations, armature winding, and shaft.

- The commutator is the segmented copper cylinder mounted on the same shaft that connects to the armature winding and interfaces with brushes.

XDC designs both the mechanical interface and electrical geometry so the armature and commutator work as a single, balanced system.

For cleaning armature commutator surfaces, XDC recommends only non-abrasive methods (lint-free wiping, vacuuming, and approved cleaning agents) during routine maintenance. Aggressive filing or sanding without respecting run-out and film requirements can damage bar edges and compromise commutation. For significant deposits or pattern defects, we advise controlled machining according to XDC’s specified turning limits rather than ad-hoc hand cleaning.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…