Angle Grinder Commutator for High-Speed Universal Motors

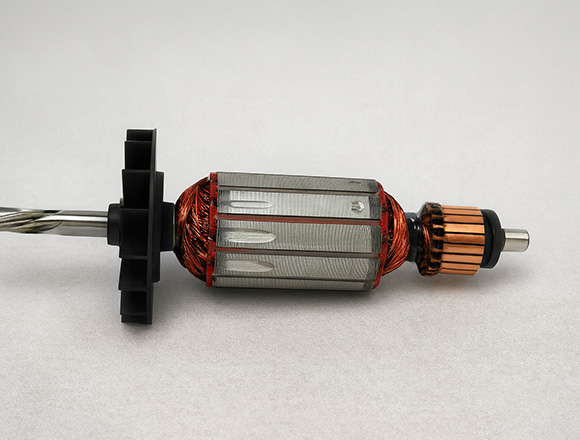

As China’s premier commutator manufacturer, XDC specializes in designing and producing the angle grinder commutator used in demanding, high-speed universal motors. Our products are engineered for power tools that routinely operate in the 4,000–16,000+ rpm range, where even minor imbalances in the commutator–armature system can quickly become noise, heat and premature wear.

Angle Grinder Commutator Manufacturer in China

From compact 4½-inch grinders to heavy-duty industrial tools, we support OEM and aftermarket customers worldwide with stable quality, tight tolerances and repeatable performance for every angle grinder commutator we ship. Angle grinders use compact universal motors where the commutator must maintain clean switching at high surface speed. Our designs focus on low electrical noise, controlled sparking and stable contact with the carbon brush system during rapid acceleration and deceleration.

Angle Grinder Commutators for Reliable, Long-Life Performance

Our angle grinder commutators are manufactured with high-conductivity copper and precise dynamic balancing to ensure stable torque, low sparking, and extended motor life. Available for a wide range of angle grinder models, we support OEM/ODM customization, strict quality inspection, and consistent batch reliability for your power tool production.

5.6mm OD 5-Bar Micro Commutator

Miniature 5-segment commutator (OD 5.6mm) with extended tabs. Designed for coreless and micro DC motors. Features high-conductivity copper for stable performance. Custom sizes and OEM specifications available.

6.5mm 6-Bar Hook Type Commutator

6-segment hook type commutator (OD 6.5mm) for small DC motors. Precision-engineered with reinforced copper hooks to ensure secure winding connections. Ideal for automotive actuators and appliances. OEM customization available.

15mm 10-Bar Hook Type Commutator

10-segment hook style commutator (OD 15mm). Features robust copper construction and precise hook geometry for automated welding. Ideal for automotive auxiliary motors (windows/seats) and household appliances. OEM/ODM services available.

11.4mm 14-Bar Hook Type Commutator

14-segment hook commutator (OD 11.4mm) for DC motors. Engineered with high-grade copper for thermal stability. Widely used in automotive window lifters and fuel pumps. Supports custom OEM production.

95.4mm 57-Bar Industrial Riser Commutator

Heavy-duty 57-segment commutator (OD 95.4mm) for industrial traction motors and forklifts. Robust riser design handles high current loads. Precision-machined silver copper ensures durability. Custom manufacturing for heavy machinery available.

25.5mm 31-Bar Fuel Pump Commutator

Specialized 31-segment commutator (OD 25.5mm) for automotive fuel pumps. Engineered with corrosion-resistant copper alloy to withstand fuel immersion. High-precision molding ensures low noise and long service life. OEM available.

17-Bar Slot Type Motor Commutator

17-segment commutator with precision-cut slots for secure wire connection. The odd-number bar design ensures reduced cogging torque and smooth operation. High-grade silver copper construction. Ideal for automotive and appliance motors. OEM supported.

36.5mm 36-Bar Reinforced Bushing Commutator

Robust 36-segment commutator (OD 36.5mm) featuring a reinforced metal hub for high-torque resistance. Designed for automotive starter motors and heavy-duty machinery. Silver-copper alloy ensures superior durability and conductivity. OEM specs welcome.

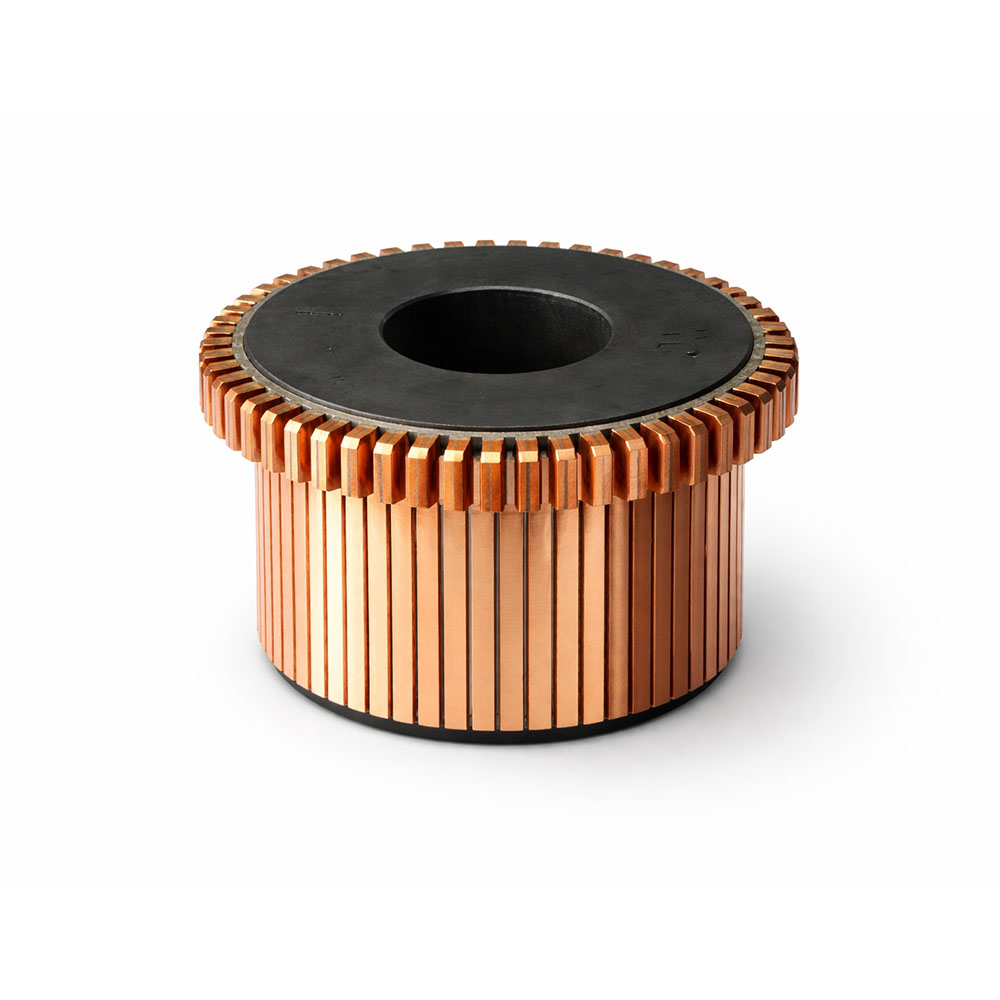

Angle grinder commutator specifications and design focus

At XDC, each angle grinder commutator is designed around the real operating conditions of a universal motor in dusty, high-load environments:

Critical geometric tolerances

To minimize bar-edge burning and vibration, we control commutator concentricity to high-speed standards.We align our machining and inspection processes around this level of precision, ensuring a stable interface between commutator, armature shaft and bearing housing.

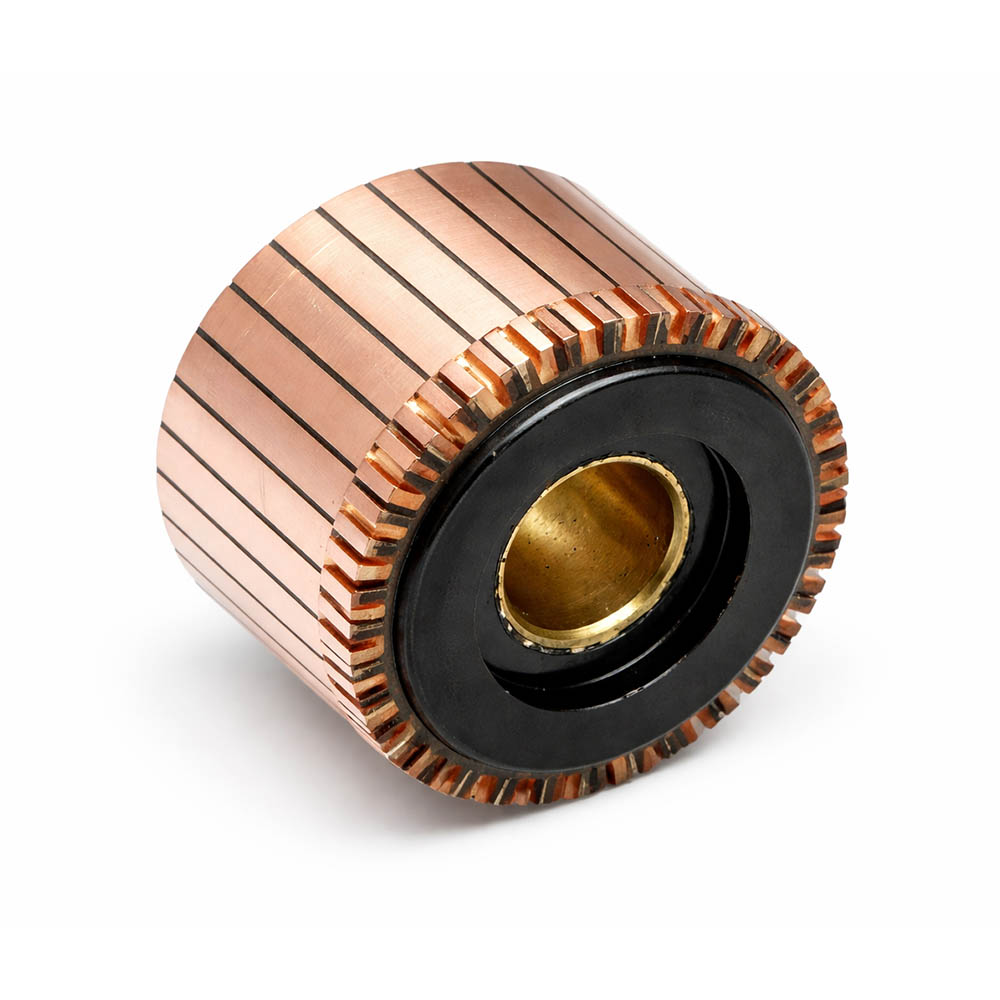

Optimized brush spring pressure (4–7 psi)

Brush pressure is a key factor in commutator and carbon brush wear. Too low, and contact becomes unstable and leads to arcing; too high, and mechanical wear accelerates. We design brush systems for a pressure in the 4–7 psi range, a band recognized as ideal for small, high-speed DC and universal motors. This balance supports smooth current transfer and longer commutator life.

Life driven by commutator, brushes and bearings

In universal motors, overall life is typically limited by commutator wear, bearing condition and the service life of several sets of brushes. Our angle grinder motor commutator designs, surface finishes and copper grades are chosen to work harmoniously with these maintenance patterns, helping your tool achieve reliable service across multiple brush changes.

Thermal and dust considerations

Universal motors generate significant heat at the commutator–brush interface, especially in grinders where load and duty cycle can be severe. XDC selects materials and insulation systems to handle elevated temperatures and abrasive dust from grinding discs, limiting carbon tracking and pitting even under tough real-world conditions.

Quality Control for XDC angle grinder commutator

Because the angle grinder commutator operates in a compact, intermittent-duty universal motor, our processes are tailored for:

- Tight control of slot insulation and riser formation for stable coil connections

- Precision alignment of commutator, armature laminations and shaft to reduce rotor-related failures

- Surface finishing optimized for fast brush seating, limiting initial sparking in new grinders

- Compatibility with common carbon brush grades used in portable power tools

The result is a robust commutator that supports clean switching, controlled sparking and long-term reliability in typical grinder duty cycles.

Why Choose Us – XDC Angle Grinder Commutator Solutions

Choosing XDC as your angle grinder commutator partner gives you:

Specialization in power-tool commutators

Our core focus is commutators for universal motors in tools like angle grinders, drills and sanders. This specialization means our team understands grinder-specific challenges such as abrasive dust, side-load, high RPM and frequent start/stop operation.

Flexible OEM and aftermarket support

Whether you need a custom grinder commutator replacement for an existing platform, or a new design for a next-generation series, we can adjust segment count, dimensions and materials to suit your motor and housing constraints.

Consistent quality from China’s premier commutator manufacturer

As XDC, we combine modern production lines with rigorous QA, ensuring batch-to-batch consistency for customers selling into Europe, North America, Asia and beyond.

Contact Us

Ready to discuss your next angle grinder commutator project?

Contact the XDC sales and engineering team with your:

- Please send us your product drawings.

- Please inform us of the quantity you require, the materials needed

- Special requirements for packaging, marking, or testing.

We will provide technical recommendations, prototype lead times and a stable production plan to support your tool program.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ – Angle Grinder Commutator & XDC Manufacturing

In many universal-motor applications, overall life is influenced by commutator wear, bearings and several sets of brushes. Typical brush-limited life falls around 1,000–3,000 operating hours, with inspection every ≈50 hours suggested. Our commutators are designed to perform reliably within these service intervals when used with appropriate brushes and maintenance.

We focus on three key areas: precise concentricity (around 0.001 inch for high-speed rotors), correct brush spring pressure in the 4–7 psi band, and surface finishes matched to the selected carbon brush grade. Together, these factors help keep sparking controlled and extend commutator and brush life.

Yes. We supply angle grinder commutator solutions compatible with a wide range of OEM designs and can customize segment count, OD/ID, length and hook type for platforms similar to Bosch, Makita, DeWalt, Metabo, Milwaukee and many others.

We combine mechanical inspections (dimensions, runout, visual bar condition) with automated electrical tests inspired by methods that achieve >98% effectiveness in detecting shorted or broken commutator segments in universal motors. This multi-layer QA strategy enhances outgoing reliability.

Brushless angle grinders use electronic commutation and do not require a mechanical commutator. While our core business is commutators and universal-motor components, we can coordinate with your team to align commutator-based and brushless product families in a single supplier strategy if required.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…