AC Commutator

An ac commutator is a rotary electrical switch mounted on the motor armature that reverses current in the rotor windings while the motor runs on alternating current. By coordinating current reversal with rotor position, an ac commutator motor produces unidirectional torque at high speed using a simple single-phase supply. This makes the technology ideal for universal motors in drills, grinders, mixers, hair dryers, vacuum cleaners, pumps and many other devices where high starting torque and high speed are critical.

Compared with a generic dc commutator, an ac version is optimized for operation on ac or ac/dc universal duty. The copper segments, insulation system and mechanical construction are carefully tuned to manage higher dv/dt, brush sparking and thermal stress on ac supply, while keeping vibration and noise low in demanding portable power tools and domestic appliances.

AC Commutator Manufacturer in China

As a leading commutator manufacturer in China, XDC supplies high-precision ac commutator components solutions for power tools, home appliances, automotive motors and industrial equipment. Our engineering team helps you translate demanding torque, speed and lifetime requirements into reliable, mass-producible designs.

We focus on copper commutators for universal motors and ac series motors. From compact 3-segment parts for small appliances to large traction and pump motors with 50+ segments, XDC covers the full range of ac commutator applications.

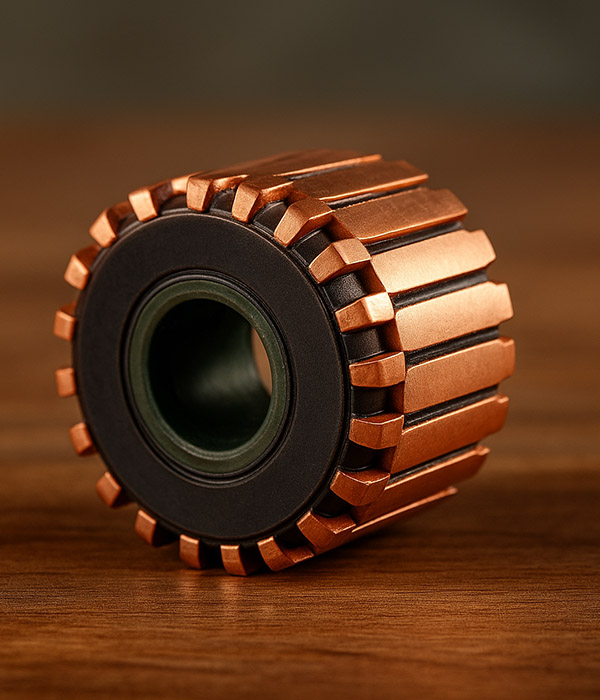

AC Commutator Manufactured by XDC

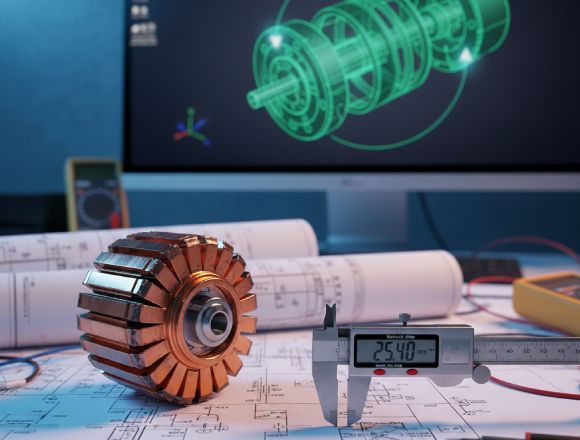

Discover our manufacturing solutions for AC commutators, widely used in high-speed universal motors. We tailor every component to your specific blueprints, ensuring perfect fit and function. Our workflow begins with rigorous prototype approval before transitioning to full-scale output. Examine our craftsmanship in the gallery below, and directly send us your drawings to get a quote.

Precision 5-Slot Micro Commutator

Offering higher switching resolution than 3-bar alternatives, this 5.6mm unit provides smoother control. Its design reduces electrical noise, making it ideal for sensitive electromechanical actuators and micro-drives.

Low-Inertia 3-Bar Commutator

With a minimal 2.9mm footprint, this 3-segment component offers exceptionally low rotational inertia. It allows for rapid motor acceleration and high responsiveness in precision micro-drive systems.

Smooth-Running 6-Slot Commutator

Delivers a significantly smoother torque curve than standard 3-segment counterparts. This 6.5mm unit minimizes mechanical vibration, making it the preferred choice for precision handheld instruments.

3-Segment Right-Angle Commutator

Engineered for automated production, the right-angle tang profile supports high-speed winding. It facilitates precise wire positioning and minimizes defects, optimizing manufacturing efficiency for high-volume motor lines.

14-Slot Precision Control Commutator

Engineered to minimize magnetic cogging, this 14-segment, 11.4mm unit enables superior low-speed control. It is the ideal component for servo motors requiring high-resolution positioning accuracy.

High-Concentricity 10-Bar Commutator

Manufactured with strict run-out tolerances, this 15mm, 10-slot unit guarantees constant brush contact. It minimizes mechanical vibration, ensuring reliable operation in industrial-grade motor applications.

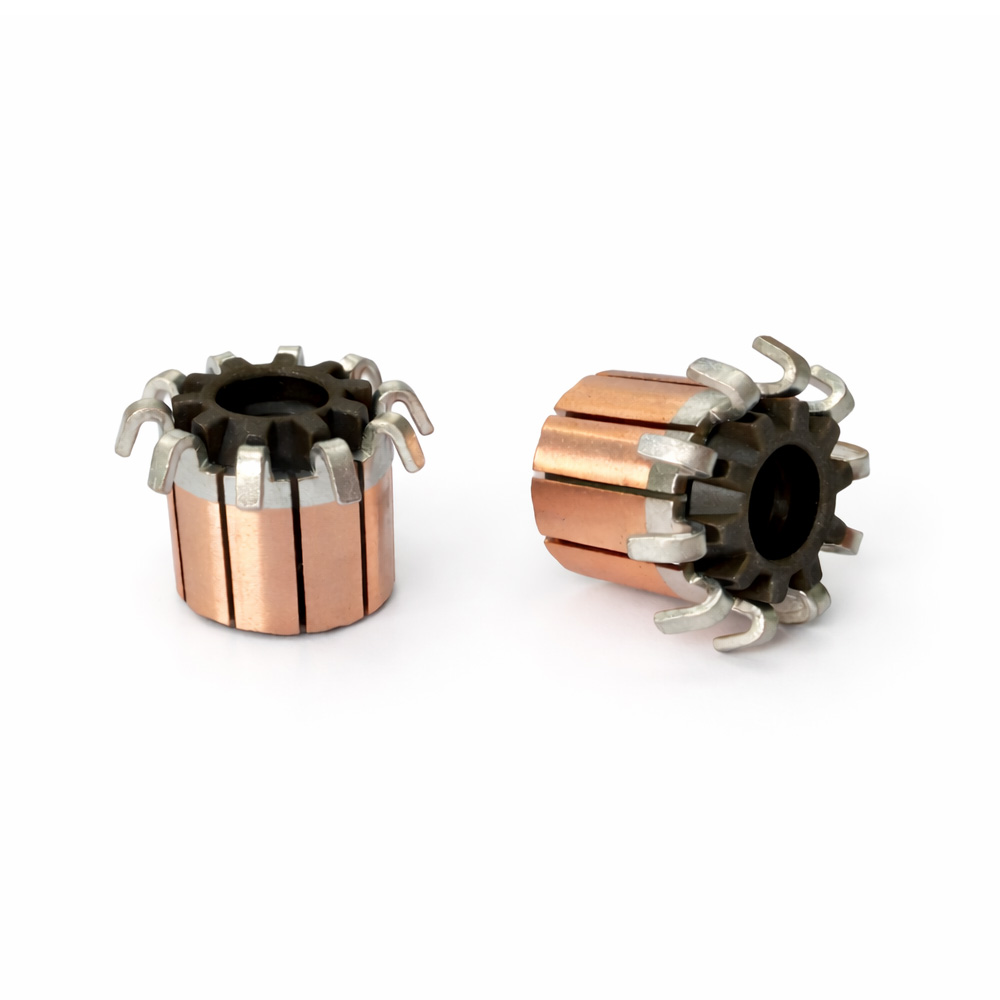

3-Segment Bent-Hook Commutator

The specialized bent hook geometry provides superior mechanical interlocking for armature windings. Designed to withstand high centrifugal forces, it effectively prevents wire detachment and ensures reliable fusing connections.

12.5mm Actuator Commutator

Specifically sized for electromechanical actuators. The 10-bar design provides stable torque output and ensures excellent durability during frequent start-stop cycles in automotive or industrial systems.

Key Features

Construction types

Hook, riser, shell and planar styles for universal motors, single-phase ac commutator designs and special rotor geometries.

Segment material

High-conductivity electrolytic copper or silver-copper (AgCu) alloys for low resistance and excellent heat dissipation at high current density.

Insulation system

Mica or high-performance resin insulation between segments, with V-ring or string-band constructions for larger industrial and traction units to ensure high dielectric strength and mechanical stability.

Mechanical performance

Tight control of concentricity and radial deviation (down to 0.015 mm), high hardness, good abrasion resistance, low angular error of segments and stable structure to reduce brush wear and commutator noise.

Customization & Engineering Support

Every ac commutator has unique needs based on torque, speed, duty cycle, acoustic targets and cost. XDC offers end-to-end engineering support:

- Selection of segment count and bar geometry for smooth torque and low commutation ripple in your universal motor.

- Optimisation of copper grade and insulation system (mica vs engineered resins) for your temperature class and environment.

- Definition of OD, ID, height and shaft fit to match existing armatures or to create new rotor platforms.

- Guidance on brush material and spring pressure to minimise sparking and brush wear on ac supply.

- Support for prototype builds, PPAP / first-article approval and validation testing for new ac commutator platforms.

Share your drawings, 3D models or physical samples with us, and our engineers will propose a matching or improved design, complete with test data and manufacturing feasibility analysis.

Quality, Testing & Reliability

Reliable operation of an ac commutator depends on both the commutator itself and the way it is manufactured. XDC integrates multiple quality steps:

- Incoming inspection of electrolytic copper, AgCu alloys, mica and resin materials.

- Precision machining of segment profiles, risers and hooks to ensure uniform current distribution.

- Molding, curing and undercutting processes controlled to maintain insulation thickness and dielectric strength.

- Dynamic balancing and run-out checks to keep vibration within strict limits.

- Electrical testing, including hi-pot, insulation resistance and spin tests at elevated temperature and speed.

This quality framework ensures that each unit leaving our factory is ready to integrate into your single-phase ac commutator or universal motor without additional rework.

Why Choose XDC as Your AC Commutator Partner?

As a specialised commutator manufacturer in China, XDC offers a combination of engineering know-how, flexible manufacturing and customer-focused service:

Complete portfolio

From tiny 2.5 mm OD shell types to 150 mm OD V-ring traction commutators, we support virtually every size of ac commutator used in tools, appliances, automotive and industrial applications.

Custom engineering

We work from your drawings or samples to define OD/ID, height, segment count, hook or riser style, insulation thickness, shaft interface and balancing requirements. Our engineers can also recommend changes to improve manufacturability or performance.

Quality & traceability

Each unit is produced under strict process controls with dimensional inspection, dynamic balancing, hi-pot and insulation resistance testing. Batch numbers and material certificates ensure full traceability from copper and insulation through to finished part.

High-volume capability

With automated production and rigorous in-line inspection, we can support multi-year supply programs for global brands in power tools, home appliances and automotive components.

Typical Applications of XDC AC Commutators

Our products are used across a wide range of industries and devices:

Power tools

Angle grinders, electric drills, sanders, circular saws and other portable power tools rely on universal motors with the commutator to deliver high starting torque and high RPM in a compact package.

Household appliances

Vacuum cleaners, blenders, mixer grinders, coffee grinders, food processors and hair dryers use single-phase universal motors where the ac commutator enables variable speed and powerful suction or mixing performance.

Pumps and blowers

Deep-water pumps, circulation pumps and small blowers use mid-size commutators for robust starting under load and reliable continuous duty.

Automotive & motorcycle motors

Window lift motors, small pumps, HVAC blowers and motorcycle motors use specialised designs, tuned for low noise and high torque.

Toys & fitness equipment

Small universal motors in toys, exercise machines and door drives use miniature assemblies with carefully selected copper and insulation systems.

Industrial & traction

Larger platforms and dc series motor systems in legacy traction and industrial machinery employ high-segment commutators that XDC can manufacture with tight process control.

Contact Us Now

Ready to develop or source your next ac commutator or ac commutator platform from a trusted manufacturer in China?

Reach out to XDC with your drawings and specifications. Our engineering and sales teams will respond with a clear technical proposal, sample plan, lead time and quotation, helping you bring reliable universal motors and ac series motors to market faster and more competitively.

XDC – Your specialist partner for ac commutator technology.

WhatApps

+86 17820674273

Address

Taixing Science and Technology Park, No. 3 Taixing Road, Dongguan City, Guangdong Province

XDC Precision Customer Feedback

What we appreciate most about XDC is how fast they reply. If there’s ever a delay or any issue, they tell us directly instead of hiding it. That makes planning on our side much easier. Their attitude is very straightforward and cooperative.

We tried a few suppliers before, but either the price was too high or the quality was unstable. XDC gave us a very reasonable price, and the commutators are performing well in our tools. Our failure rate in testing has clearly gone down since we switched to them.

During a new motor project, XDC helped us adjust the design of the commutator several times. They gave practical suggestions instead of just doing exactly what we asked. That saved us time and a lot of trial and error. We’re very satisfied with the technical support from their team.

We’ve placed some urgent orders with XDC, especially before peak season. They managed to deliver on time and kept us updated on the production schedule. This helped us avoid shortages and kept our production line running smoothly.

We’re based in Europe and were a bit worried about the time difference at first. But the XDC sales team arranges calls at times that work for us, and emails are answered quickly. The communication has been very smooth, so the distance hasn’t been a problem.

FAQ

A dc motor uses a commutator designed only for direct current, while an ac motor uses a commutator optimized for single-phase ac or universal (ac/dc) operation. The ac design manages higher voltage reversals, additional losses and brush sparking associated with ac supply, so it needs different insulation systems, segment geometry and sometimes compensating windings.

Yes. If you already have a universal motor design, we can match your current commutator using drawings, specifications or samples. We will replicate key parameters such as OD, ID, height, number of segments, hook style, insulation system and shaft interface, and can also recommend improvements for lifetime or cost.

For a new ac commutator, we typically ask for target voltage and frequency, power and speed, required torque, duty cycle, approximate motor frame size, preferred brush grade and any specific standards you need to meet. From there, we propose segment count, material selection and detailed dimensions for the commutator.

An ac series motor with a commutator generally offers higher starting torque and much higher speed in a smaller frame than a comparable induction motor. This is why these motors are widely used in drills, grinders, mixers and vacuum cleaners where compact size and strong acceleration are important, even though brushless and induction solutions exist.

Brush wear and commutator life depend on brush material, spring pressure, surface finish, segment geometry, operating temperature, speed and supply waveform. Good contact pressure, correct brush seating, smooth surfaces and appropriate copper and insulation choices all help extend life and reduce maintenance.

Yes. For development projects we can provide lower-volume prototype lots, while our standard production lines monthly outputs in the hundreds of thousands or more. This allows you to start small and scale to full mass production with the same supplier.

Related Resource

At XDC, we share our deep insights into commutators, manufacturing processes, and industry experience on our blog. We invite you to explore these articles to learn more about our expertise.

What Is a Commutator? A Guide for DC Motor Buyers & Engineers

1. Quick Overview: Why Commutators Matter in Real Projects If you buy or design DC motors or DC geared…

Why Your Power Tool Motor Sparks at the Commutator (Focus on Tool Specifics)

Most of the sparks you see through those vent slots are either perfectly normal or a quiet warning that…

Future of Commutator Motors in a Brushless-Dominated Market

If you spend any time around electric drives today, it feels like everything is going brushless. New specs ask…